Drilling pile with a bar-reinforced squeezed branch-plate, and construction method thereof

A technology of supporting disk piles and reinforcement, which is applied to sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of weak shear resistance, unstable hole walls, and debris easily slumped, and improve the shear strength. , Avoid adverse effects, improve the effect of pile foundation bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

[0044] In the embodiment of the present invention, the construction technical requirements such as elastic film production, steel cage binding, drilling into holes, and support plate extrusion and expansion will not be described in detail, but the embodiment of the present invention will be explained in detail. The present invention will be further described below in conjunction with the accompanying drawings and examples. Detailed description, the description is not limited to the following examples.

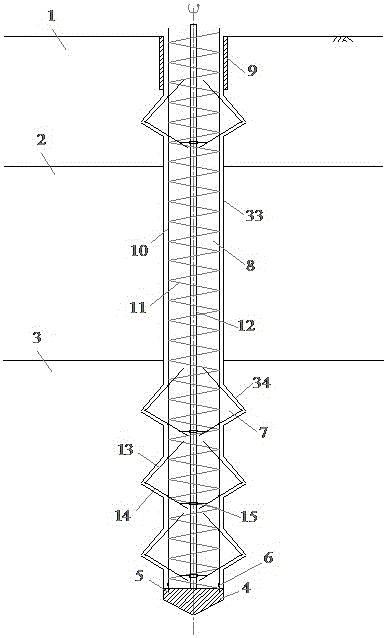

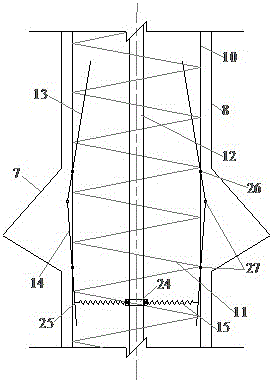

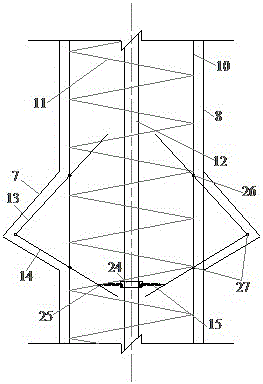

[0045] Such as Figure 1-10 As shown, the drilled and extruded reinforced abutment pile of the present invention includes a prefabricated pile tip 4, a pile body of equal section 8, a support disc body 7, a longitudinal main reinforcement 10, a spiral stirrup 11, an upper inclined reinforcement 13 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com