Integrally-formed low-gram-weight composite air-laid paper

A dust-free paper, low-weight technology, applied in the direction of textiles and papermaking, non-woven fabrics, adhesives, etc., can solve the problems of small fiber web gaps, easy SAP leakage, skin allergies, etc., and achieve the effect of improving dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

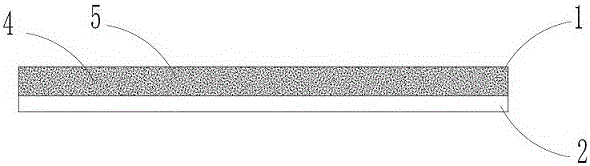

[0057] as attached figure 1 As shown, the surface layer of the once-formed low-grammage composite dust-free paper described in this embodiment is an air-formed dust-free paper layer 1 composed of fluff pulp fibers and ultrafine hot-melt short fibers, and the bottom layer is a non-woven fabric layer 2; An adhesive layer 3 is arranged between the non-woven fabric layer 2 and the air-formed dust-free paper layer 1 .

[0058]In this embodiment, the dust-free paper layer 1 is composed of fluff pulp fibers 4 and ultrafine hot-melt short fibers 5, the content of fluff pulp fibers 4 is 65%; the content of ultrafine hot-melt short fibers 5 is 35%, and the content of fluff pulp fibers The length of the fiber 4 is 2~3mm, and the width is 40μm; the superfine hot-melt short fiber 5 is a two-component ES fiber, the melting point of the outer layer is 135°C, the melting point of the inner layer is 155-160°C, and the square grams of fluff pulp Weight is 10g / m 2 , the square gram weight of u...

Embodiment 2

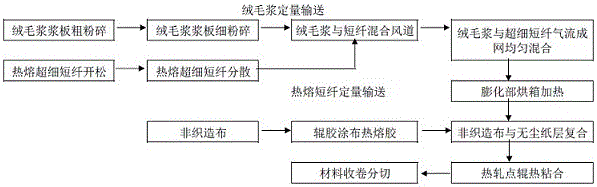

[0074] as attached figure 2 As shown, the one-time forming low-grammage composite dust-free paper structure described in this embodiment has an air-formed dust-free paper layer 1 composed of fluff pulp fibers and ultra-fine hot-melt short fibers on the surface layer, and a non-woven dust-free paper layer on the bottom layer. Cloth layer 2.

[0075] In this embodiment, the dust-free paper layer 1 is composed of fluff pulp fibers 4 and ultrafine hot-melt short fibers 5, the content of fluff pulp fibers 4 is 65%; the content of ultrafine hot-melt short fibers 5 is 35%, and the fluff pulp fibers The length of 4 is 2~3mm, and the width is 40μm; the superfine hot-melt short fiber 5 is a two-component ES fiber, the melting point of the outer layer is 135°C, the melting point of the inner layer is 155-160°C, and the square gram weight of fluff pulp 16g / m 2 , the square gram weight of ultra-fine hot-melt staple fiber is 9g / m 2 .

[0076] In this embodiment, the hydrophilic nonwove...

Embodiment 3

[0091] In this embodiment, the adhesive uses hot-melt pressure-sensitive adhesive of SBS system, the melting temperature is 2000-2600cps / 160°C, and the softening point is 70-80°C.

[0092] The manufacturing process parameters of the low-weight composite dust-free paper in this implementation case are as follows:

[0093] 1) The coarse crushing power of the fluff pulp board is 15kw, the electrode speed is 1400-1500r / min, and the crushing capacity is 200kg / min;

[0094] 2) The power of the fluff pulp fine pulverizer is 50kw, the electrode speed is 1400-1500r / min, and the defibrating capacity is 200kg / min;

[0095] 3) The power of the opening machine is 2kw, and the air volume of the negative pressure fan in the forming part is 8000-12000m 3 / h;

[0096] 4) The power of the mixed fan of fluff pulp fiber and ultrafine hot-melt short fiber is 20-30kw, and the processing air volume is 4000-8000m 3 / h;

[0097] 5) The air duct section of the oven adopts multi-stage heating, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Square gram weight | aaaaa | aaaaa |

| Square gram weight | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com