Wine aging method

An old-fashioned, wine technology, applied in the preparation of alcoholic beverages, etc., can solve the problem of large consumption of wine, and achieve the effect of increasing the aroma of wine, softening the taste, and reducing spiciness.

Inactive Publication Date: 2016-10-12

辽宁慧能通机电科技有限公司

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, alcohol consumption is high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0032] The aging method of a kind of wine described in embodiment two is basically the same as embodiment one, and its difference is: the water pressure in the soft isolation bag 8 is 55-100Mpa.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

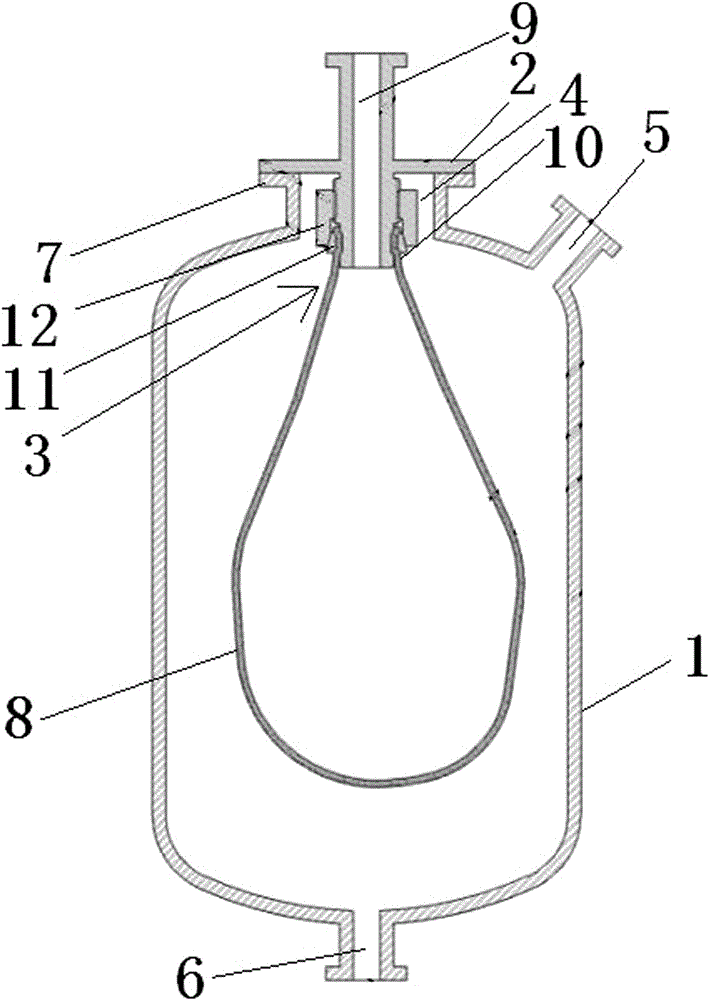

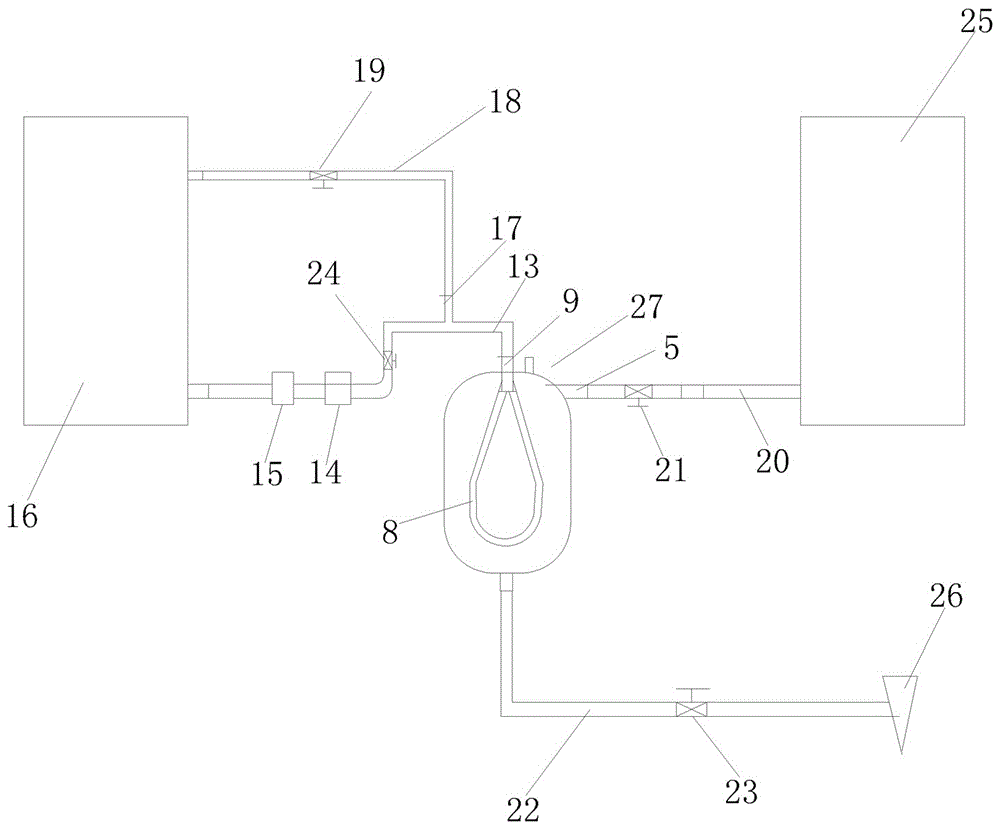

A wine aging method adopts an autoclave with a soft isolation chamber inside. The method is as below: pumping the wine inside the autoclave, closing a valve on a wine transportation pipeline, starting a water pump to pump water in a water storage tank into a soft isolation bag by a pressure booster, holding the pressure at 20-440mpa for 20 min to 1 h, opening a valve on a water return pipeline, returning water in the soft isolation bag back to the water storage tank, closing the valve on the water return pipeline, and sending the wine to aseptic filling equipment by a discharging pipe. The invention has the advantages that the sterilization rate is lower than the national standard, and is lower than the European Union standard, so as to improve the quality of the wine; the quality guarantee period of the wine is improved by 10 to 15 days; the nutritional composition of the wine is improved, which is convenient for the human body to absorb; and the taste is good. The wine is not processed by a high pressure pump, and is isolated from a pressurization medium to avoid secondary pollution.

Description

technical field [0001] The invention relates to a wine brewing process, in particular to a wine aging method. Background technique [0002] Wine is an alcoholic beverage that Chinese people like to drink very much. Whenever there are holidays, especially gatherings of relatives and friends, wine is often a must-have item on the table. Therefore, alcohol consumption is high. [0003] After the wine is brewed, it needs to be stored for a period of time to make the wine taste soft, the aroma increase, and the wine body become harmonious. [0004] Slow chemical changes can also occur during the storage of wine to generate new product esters, which can endow the liquor with an ester aroma. [0005] Because the storage period of wine is long, a large amount of storage containers and capital turnover will be taken. Contents of the invention [0006] The object of the present invention is to provide a method for aging wine, which can accelerate the aging process of wine, improv...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C12H1/22

CPCC12H1/22

Inventor 刘斌杨猛

Owner 辽宁慧能通机电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com