Plant enzyme environment-friendly laundry detergent sheet and preparation method thereof

A technology of plant enzymes and production methods, applied in chemical instruments and methods, detergent powder/flakes/sheets, detergent materials, etc., can solve the problems of easy waste of large packages, environmental pollution of detergents, and difficulty in carrying laundry detergents, etc. , to achieve the effect of enhancing the stimulating effect and improving the decontamination ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

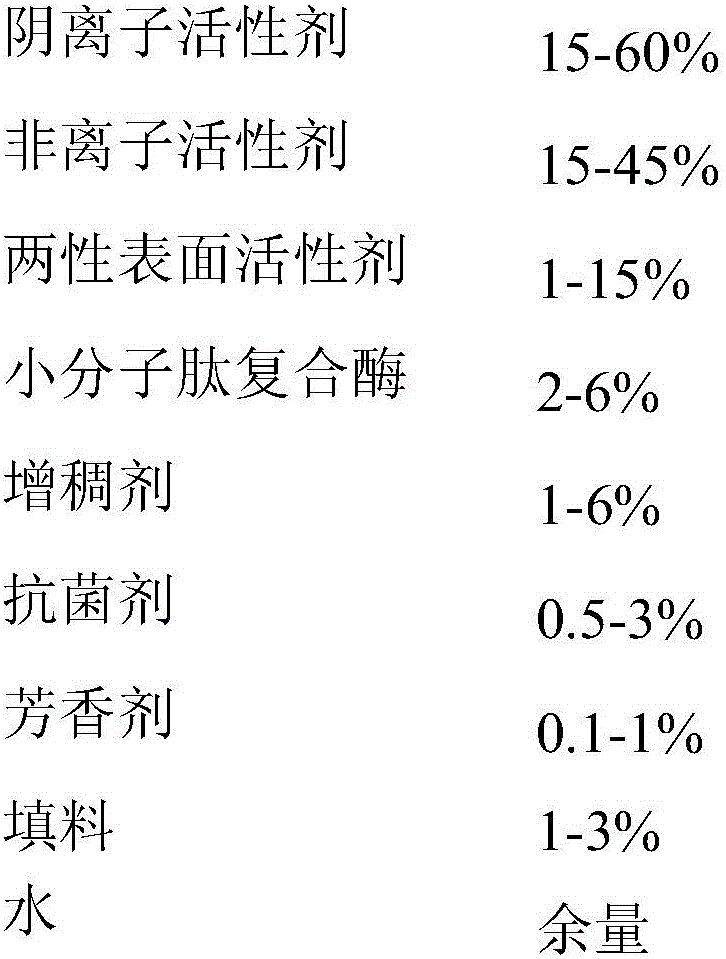

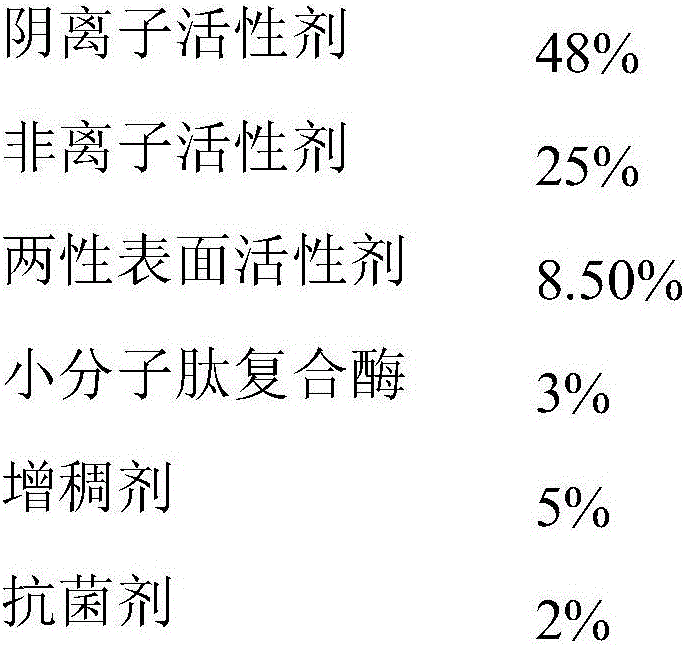

Method used

Image

Examples

Embodiment 1

[0031] A plant enzyme laundry tablet, which is prepared by the following method;

[0032] Step S001, get 45 grams of anionic active agent sodium lauryl glutamate, 31 grams of non-ionic decyl glucoside, 5 grams of amphoteric surfactant dodecyl dimethyl sulfopropyl betaine, put into the preparation container and stirring constantly;

[0033] Then take 3.8 grams of thickening agent xanthan gum, 2.5 grams of antibacterial agent sodium hydroxymethyl glycinate, 2 grams of filler corn starch, 0.5 grams of aromatic essence, and an appropriate amount of deionized water, also put them into the preparation container, and keep stirring. Homogenize and mix the components fully to obtain the raw materials for liquid plant enzyme laundry tablets;

[0034] Step S002, placing the raw material for making the liquid plant enzyme laundry tablet prepared in the above step S001 in a drying device for water evaporation, and intelligently controlling the thickness of the liquid plant enzyme laundry ...

Embodiment 2

[0041] A plant enzyme laundry tablet, which is produced by the following method;

[0042] Step S001, mixing 8 grams of anionic active agent sodium lauryl glutamate, 6 grams of sodium lauroyl sarcosinate, and 14 grams of potassium lauryl glycinate, thereby forming a total mass of 28 grams and a mixing ratio of 4:3:7 mixed anionic active agent;

[0043] Mix 20 grams of non-ionic active agent decyl glucoside and 22 grams of N-acyl glutamic acid diester to form a mixed non-ionic active agent with a total mass of 42 grams and a mixing ratio of 10:11;

[0044] The amphoteric surfactant coco imidazoline (CAMA for short) 6 grams, cocamidopropyl dimethyl betaine (CAB for short) 8 grams are mixed, thus the composition total mass is 14 grams, and the mixing ratio is 3:4 mixed amphoteric surfactants;

[0045] Put the above-mentioned mixed anionic active agent, nonionic active agent and amphoteric surfactant into the preparation container and keep stirring, then get 3 grams of the mixtur...

Embodiment 3

[0056] A kind of plant enzyme laundry tablet, this plant enzyme laundry tablet is made by following method;

[0057] Step S001, mixing 21 grams of sodium lauryl glutamate and 35 grams of sodium lauroyl sarcosinate to form a mixed anionic active agent with a total mass of 56 grams and a mixing ratio of 3:5;

[0058] 4 grams of non-ionic active agent glycerol monopyrrolidone carboxylate, 6 grams of N-acyl glutamic acid diester, and 14 grams of alkyl glycosides are used to form a mixed type with a total mass of 24 grams and a mixing ratio of 2:3:7 non-ionic active agent;

[0059] Put the above mixed anionic active agent and nonionic active agent into the preparation container and keep stirring, then take 7 grams of amphoteric surfactant decanyl dimethyl hydroxypropyl sulfobetaine, thickener xanthan 2.5 grams of the mixture of glue and sodium alginate, 0.3 grams of antibacterial agent sodium carboxymethylglycinate, 0.2 grams of fragrance essence, 1 gram of filler cornstarch, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com