Low-carbon acid gas removal technique and system for high methane gas

A process method, methane-enriched technology, applied in gas fuel, petroleum industry, fuel and other directions, can solve huge environmental, industrial development disputes and restrictions, etc., to reduce atmospheric emissions, reduce construction investment and operation consumption, and economic benefits. obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

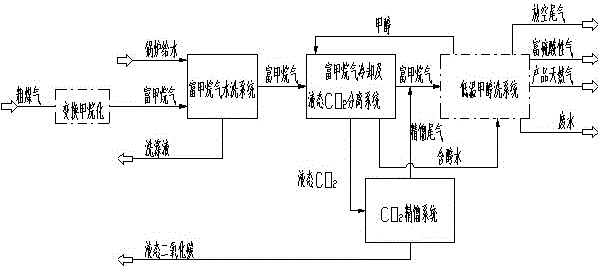

Image

Examples

Embodiment 1

[0023] see figure 2 , the crude gas produced by SHELL waste boiler process pulverized coal gasification technology enters the shift methanation system, the temperature of the crude gas is 167°C, the pressure is 3.8MPa (A), the CO content is 70.96% (dry basis, volume), H 2 The content is 19.97% (dry basis, volume), CO 2 The content is 7.58% (dry basis, volume). The crude gas reacts in the shift methanation system to produce CO rich 2 and CH 4 The methane-enriched gas is sent to the low-carbonic gas removal system of the present invention after cooling and gas-liquid separation treatment. The temperature is controlled at about 40°C, the pressure is about 3.0MPa (A), and the CO 2 The content is 69.49% (dry basis, volume), CH 4 The content is 28.20% (dry basis, volume).

[0024] In the present invention, the methane-enriched gas is firstly cooled to about 10°C through the 1# methane-enriched gas cooler 1, and then enters the methane-enriched gas water washing tower 2, and is...

Embodiment 2

[0026] see figure 2 , the crude gas produced by GE coal-water slurry gasification technology enters the shift methanation system, the temperature of the crude gas is 242°C, the pressure is 6.5MPa (A), the CO content is 41.77% (dry basis, volume), H 2 The content is 34.81% (dry basis, volume), CO 2 The content is 22.72% (dry basis, volume). The crude gas reacts in the shift methanation system to produce CO rich 2 and CH 4 The methane-enriched gas is sent to the low-carbonic gas removal system of the present invention after cooling and gas-liquid separation treatment. The temperature is controlled at about 40°C, the pressure is about 5.5MPa (A), and the CO 2 The content is 69.32% (dry basis, volume), CH 4 The content is 29.35% (dry basis, volume).

[0027] In the present invention, the methane-enriched gas is first cooled to about 15°C by the 1# methane-enriched gas cooler 1, and then enters the methane-enriched gas water washing tower 2, and is washed with boiler feed wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com