Special master batch for plastic weaving high-speed wire drawing machines and method for preparing special master batch

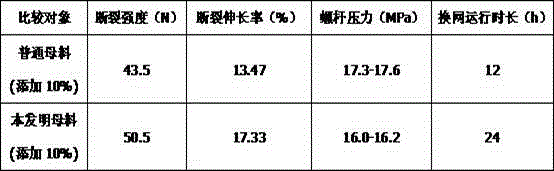

A wire drawing machine, high-speed technology, applied in the field of plastics, can solve the problems of poor flatness of woven bags, high automatic screen changing frequency, low peel strength, etc., and achieve the effect of less agglomeration, narrow molecular distribution, and improved product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: every portion is 1kg

[0016] A special masterbatch for plastic braided high-speed wire drawing machine, which is made of the following raw materials in parts by weight:

[0017] Polyethylene LLDPE 20 parts

[0018] Polyethylene LDPE 10 parts

[0019] Polyethylene HDPE 5 parts

[0020] Nano calcium carbonate 60 parts

[0021] Amphiphilic coupling agent 0.5 parts

[0022] Polyethylene wax 3.5 parts

[0023] The nucleating agent of β crystal form is 0.5 part of βNU-100

[0024] Grinding aid ZMF-01 0.2 parts

[0025] The preparation method of the special masterbatch for the above-mentioned plastic braided high-speed wire drawing machine comprises the following steps:

[0026] 1) Spray the grinding aid on the surface of calcium carbonate, and then transport it to the ring roller micro-powder mill for secondary crushing through the screw, and grind it to more than 2000 mesh to make a semi-finished product for use; 2) Add the semi-finished product to the ...

Embodiment 2

[0027]Embodiment 2: every portion is 500g

[0028] A special masterbatch for plastic braided high-speed wire drawing machine, which is made of the following raw materials in parts by weight:

[0029] Polyethylene LLDPE 10 parts

[0030] Polyethylene LDPE 3 parts

[0031] Nano calcium carbonate 15 parts

[0032] 65 parts of heavy calcium carbonate

[0033] Titanate coupling agent 1.5 parts

[0034] Polyethylene wax 3 parts

[0035] 2 parts paraffin

[0036] The nucleating agent of β crystal form is 0.3 part of βNU-100

[0037] Grinding aid ZMF-01 0.15 parts

[0038] The preparation method of the special masterbatch for the above-mentioned plastic braided high-speed wire drawing machine comprises the following steps:

[0039] 1) Spray the grinding aid on the surface of calcium carbonate, and then transport it to the ring roller micro-powder mill for secondary crushing through the screw, and grind it to more than 2000 mesh to make a semi-finished product for use; 2) Add t...

Embodiment 3

[0040] Embodiment 3: every portion is 30g

[0041] A special masterbatch for plastic braided high-speed wire drawing machine, which is made of the following raw materials in parts by weight:

[0042] 12 parts polypropylene

[0043] 83 parts of heavy calcium carbonate

[0044] 2 parts stearic acid

[0045] Polyethylene wax 2 parts

[0046] 1 part white oil

[0047] β crystal nucleating agent is βNU-100 0.1 parts

[0048] Grinding aid ZMF-01 0.05 parts

[0049] The preparation method of the special masterbatch for the above-mentioned plastic braided high-speed wire drawing machine comprises the following steps:

[0050] 1) Spray the grinding aid on the surface of calcium carbonate, and then transport it to the ring roller micro-powder mill for secondary crushing through the screw, and grind it to more than 2000 mesh to make a semi-finished product for use; 2) Add the semi-finished product to the In a high-speed mixer with a constant temperature of 110°C, divide the surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com