Sealing pad for engine of automobile and method for preparing sealing pad

A technology for automotive engines and gaskets, applied in the field of automotive sealing materials, can solve problems such as metal corrosion, swelling, and gasket sealing performance degradation, and achieve the effects of reducing swelling, good barrier properties, and excellent hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

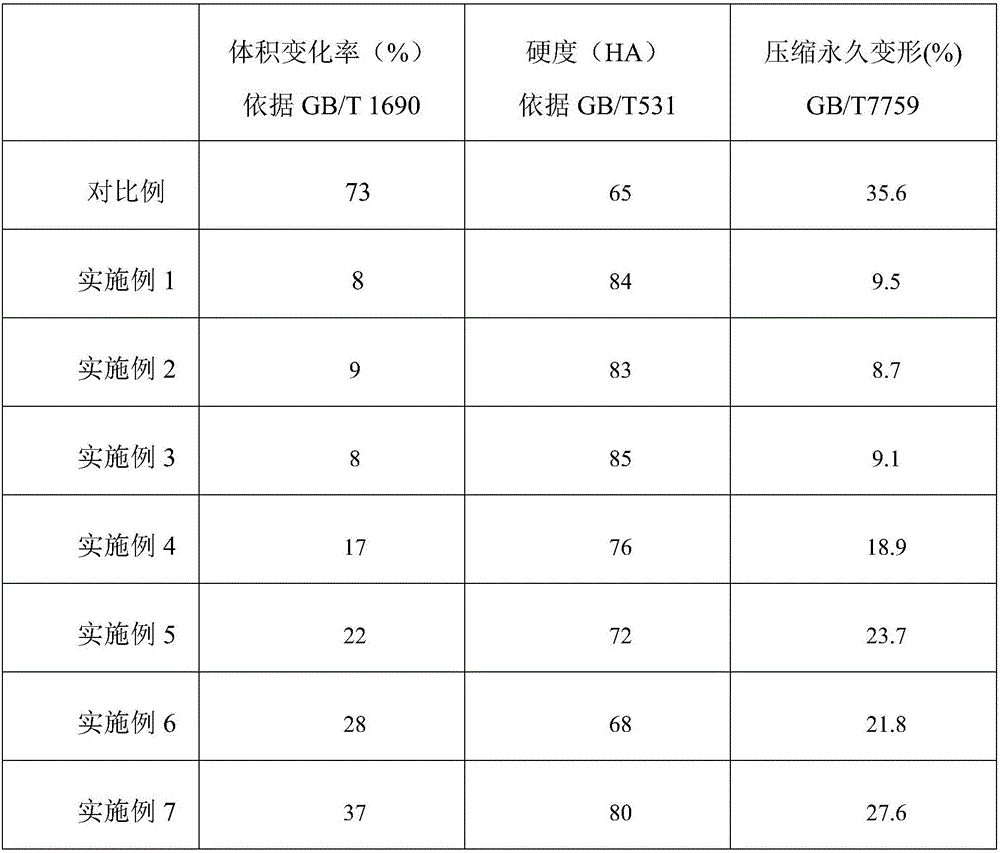

Examples

preparation example Construction

[0034] A preparation method for an automobile engine gasket, comprising the steps of:

[0035] (a) adding the silane coupling agent to the glass microspheres, fully stirring to obtain surface-treated glass microspheres;

[0036] (b) adding the isoprene rubber and the treated glass beads to an internal mixer for banburying to obtain glass beads

[0037] Filled with isoprene rubber, the mixing process parameters are 110°C-130°C, 10min-14min;

[0038] (c) adding nitrile rubber, styrene-butadiene rubber, modified nano-montmorillonite, vulcanizing agent, tert-butylphenol formaldehyde resin and glass microsphere filled isoprene rubber into a banbury mixer to obtain a mixed adhesive The refining process parameters are 130°C-145°C, 10min-14min;

[0039] (d) adding the mixed rubber in step (c) to an open mill for mixing to obtain rubber sheets, and the roll temperature of the open mill is 40°C-50°C;

[0040] (e) Put the rubber sheet obtained in step (d) into a flat vulcanizer for vu...

Embodiment 1

[0050] A kind of automobile engine gasket of the present embodiment has the following components: 45 parts by weight of nitrile rubber, 22 parts by weight of isoprene rubber, 20 parts by weight of styrene-butadiene rubber, 4 parts by weight of hollow glass microspheres, modified 5 parts by weight of nano-montmorillonite, 3 parts by weight of vulcanizing agent dicumyl peroxide, 0.7 parts by weight of silane coupling agent KH550, and 0.3 parts by weight of tert-butylphenol formaldehyde resin.

[0051] A preparation method for an automobile engine gasket, comprising the steps of:

[0052] (a) adding the silane coupling agent to the glass microspheres, fully stirring to obtain surface-treated glass microspheres;

[0053] (b) adding isoprene rubber and treated glass microspheres into a banbury mixer for banburying to obtain isoprene rubber filled with glass microspheres, and the banburying process parameters are 110°C and 10min;

[0054] (c) adding nitrile rubber, styrene-butadien...

Embodiment 2

[0059] A kind of automobile engine gasket of the present embodiment has the following components: 58 parts by weight of nitrile rubber, 18 parts by weight of isoprene rubber, 17 parts by weight of styrene-butadiene rubber, 2 parts by weight of hollow glass microspheres, modified 3 parts by weight of nano-montmorillonite, 1 part by weight of vulcanizing agent dicumyl peroxide, 0.4 parts by weight of silane coupling agent KH550, and 0.6 parts by weight of tert-butylphenol formaldehyde resin.

[0060] A preparation method for an automobile engine gasket, comprising the steps of:

[0061] (a) adding the silane coupling agent to the glass microspheres, fully stirring to obtain surface-treated glass microspheres;

[0062] (b) adding isoprene rubber and treated glass microspheres to an internal mixer for banburying to obtain isoprene rubber filled with glass microspheres, and the banburying process parameters are 130°C and 14min;

[0063] (c) adding nitrile rubber, styrene-butadiene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com