Method for degrading organic dye wastewater through graphene electrode and photoelectric Feton cooperatively

A technology for organic dyes and wastewater, applied in chemical instruments and methods, energy wastewater treatment, light water/sewage treatment, etc., can solve the problems of poor degradation effect of dye wastewater, achieve improved mineralization, easy control of conditions, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

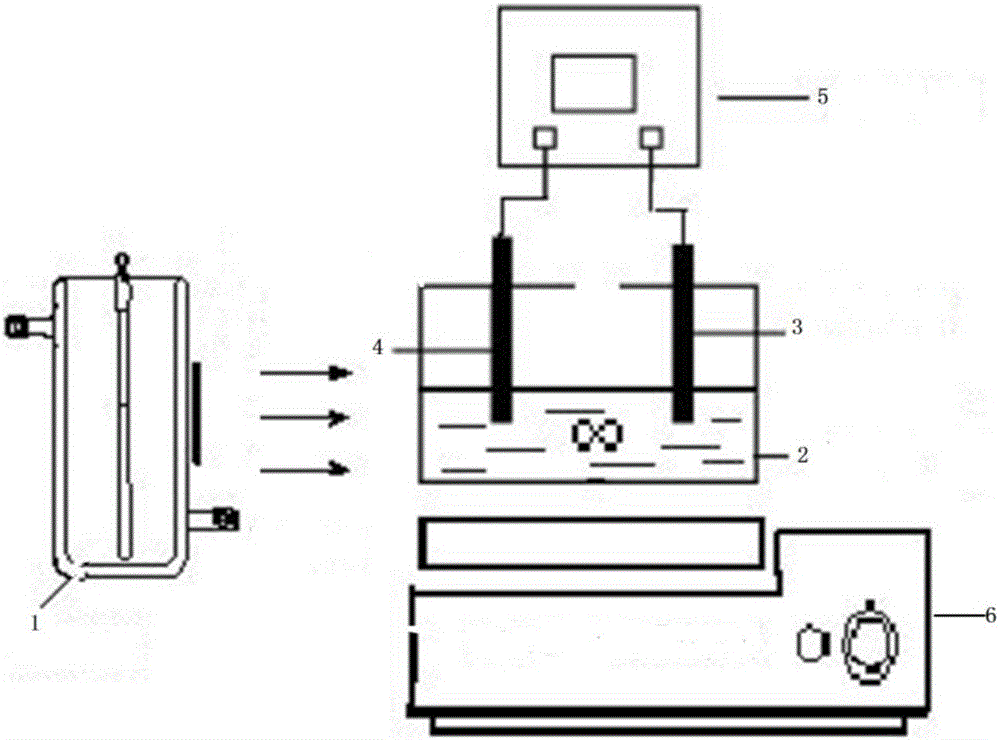

[0029] The present invention, the method for degrading organic dye wastewater, specifically comprises the following steps:

[0030] First prepare graphite composite electrode, weigh 10g of graphite, add 2 drops of "OP" emulsifier, 3mL of absolute ethanol and 1.0g of polytetrafluoroethylene, ultrasonically disperse evenly until the mixture forms a cohesive paste, then roll the paste A film with a thickness of 2 mm is attached to a stainless steel mesh, pressed under a pressure of 30 MPa to obtain an electrode, soaked in acetone solution for 2 hours to remove residual ethanol and "OP" emulsifier on the surface of the electrode; heat at 80°C for 2 hours in an infrared box, and it is ready. Graphite electrode, its final size: bottom area × height = 1.0cm 2 ×5mm;

[0031] Secondly, the prepared graphite composite electrode is used as the cathode, and the iron sheet is used as the anode, and the Rhodamine B dye wastewater is thrown into the electrolytic cell. The dosage of the Rhod...

Embodiment 2

[0035] The present invention, the method for degrading organic dye wastewater, specifically comprises the following steps:

[0036] To prepare a graphene composite electrode, weigh 8g of graphene, add 1 drop of "OP" emulsifier, 2mL of absolute ethanol, and 1.0g of polytetrafluoroethylene, and disperse evenly with ultrasound until the mixture forms a cohesive paste. Press it into a film of about 2mm, attach it to a stainless steel mesh, press it under a pressure of 20MPa to obtain an electrode, soak it in acetone solution for 2 hours to remove the residual ethanol and "OP" emulsifier on the surface of the electrode; keep it in an infrared box at 80°C for 2 hours, and the product is ready. Graphite electrode, its final size: bottom area × height = 1.0cm 2 ×5mm;

[0037] The prepared graphene electrode is the cathode, the iron sheet is the anode, the dosage of rhodamine B dye wastewater is 5g / L, and the applied voltage of the electric Fenton system is 4V; the sulfuric acid adjus...

Embodiment 3

[0040] The present invention, the method for degrading organic dye wastewater, specifically comprises the following steps:

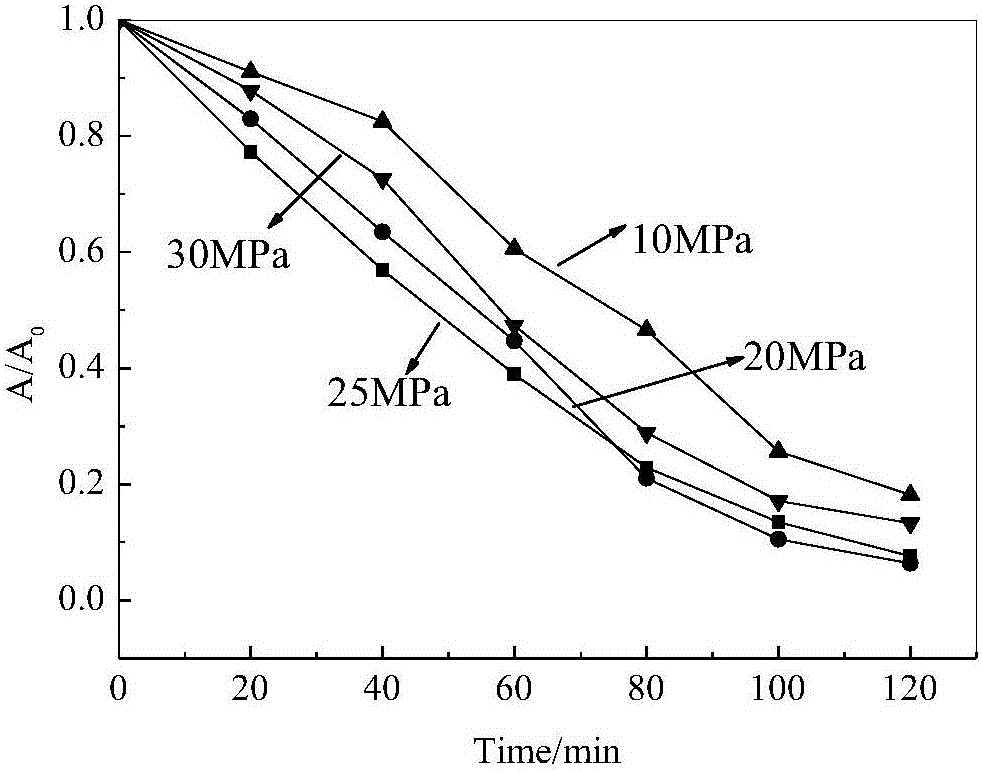

[0041] Weigh 8.5g of graphene, add 1 drop of "OP" emulsifier, 2.5mL of absolute ethanol and 1.0g of polytetrafluoroethylene, ultrasonically disperse evenly until the mixture forms a cohesive paste, and roll the paste to about A 2mm membrane is attached to a stainless steel mesh, pressed under different pressures to obtain a graphene electrode, soaked in acetone solution for 2 hours to remove the residual ethanol and "OP" emulsifier on the electrode surface, and kept at 80°C for 2 hours in an infrared box to make graphite Electrode, its final size: bottom area × height = 1.0cm 2 ×5mm;

[0042] The prepared high-purity graphite electrode is used as the cathode, the iron sheet is used as the anode, the dosage of the methyl orange dye wastewater is 4g / L, and the applied voltage of the electric Fenton system is 4V; the sulfuric acid adjusts the pH to 3.0, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com