A flue gas conveying device for secondary brine purification and its use method

A brine purification and conveying device technology, applied in magnesium halide, alkali metal halide purification, alkali metal chloride and other directions, can solve problems such as affecting the normal use of flue gas compressors, affecting equipment, reducing service life, etc., and achieving a simple structure. , The effect of stable pressure and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

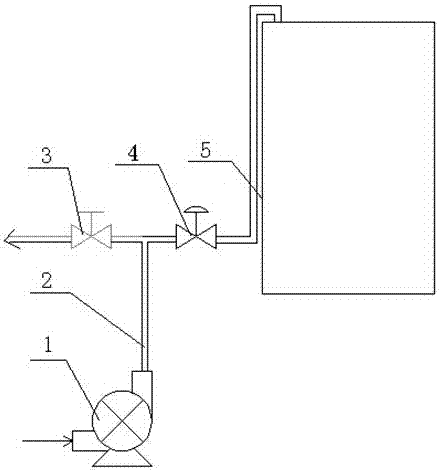

[0018] refer to figure 1 , a flue gas delivery device for secondary brine purification of the present invention, comprising a flue gas compressor 1, a control valve 4 and a safety valve 3; the flue gas compressor 1 is communicated with the flue gas delivery pipe, and the compressed The flue gas is transported to the bottom of the brine purification reaction barrel 5; the flue gas delivery pipe includes a main flue gas delivery pipe 2 and a branch flue gas delivery pipe 6, and the outlet of the branch flue gas delivery pipe 6 and the main flue gas delivery pipe 2 The control valve 4 is provided on the branch smoke delivery pipe 6; one end of the safety valve 3 communicates with the main smoke delivery pipe 2, and the other end communicates with the atmosphere.

[0019] The rated pressure of the safety valve 3 is 0.2MPa.

[0020] The distance between the end of the branch flue gas conveying pipe 2 and the bottom of the brine purification reaction barrel 5 is ≤1.0m.

[0021] In...

Embodiment 2

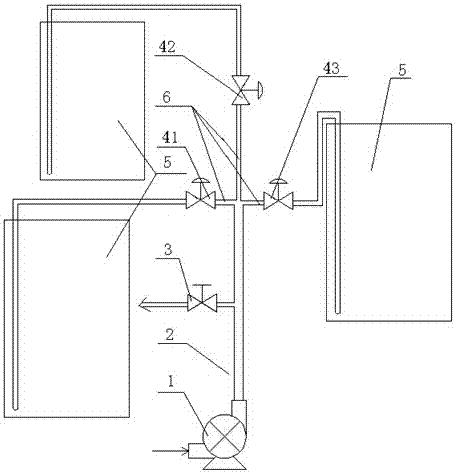

[0025] refer to figure 2 , a flue gas delivery device for secondary brine purification of the present invention, comprising a flue gas compressor 1, 3 control valves 4 and a safety valve 3; the flue gas compressor 1 is communicated with the flue gas delivery pipe, and the compressed The flue gas is transported to the bottom of the brine purification reaction barrel 5; the flue gas delivery pipe includes the main flue gas delivery pipe 2 and 3 branch flue gas delivery pipes 6, and the 3 branch flue gas delivery pipes 6 are connected in parallel to the main flue gas The gas outlet end of the conveying pipe 2; the branch smoke conveying pipe 6 is provided with a control valve 4; one end of the safety valve 3 communicates with the main smoke conveying pipe 2, and the other end communicates with the atmosphere.

[0026] The rated pressure of the safety valve 3 is 0.3MPa.

[0027] The control valve 4 includes a first control valve 41 , a second control valve 42 and a third control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com