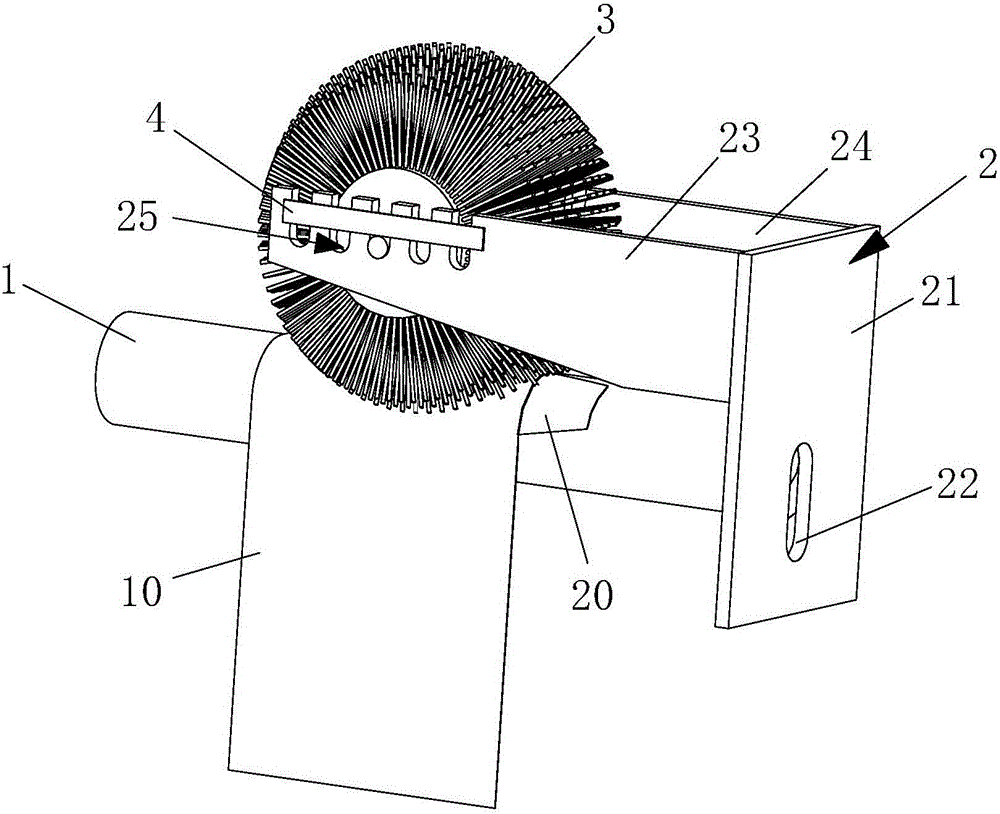

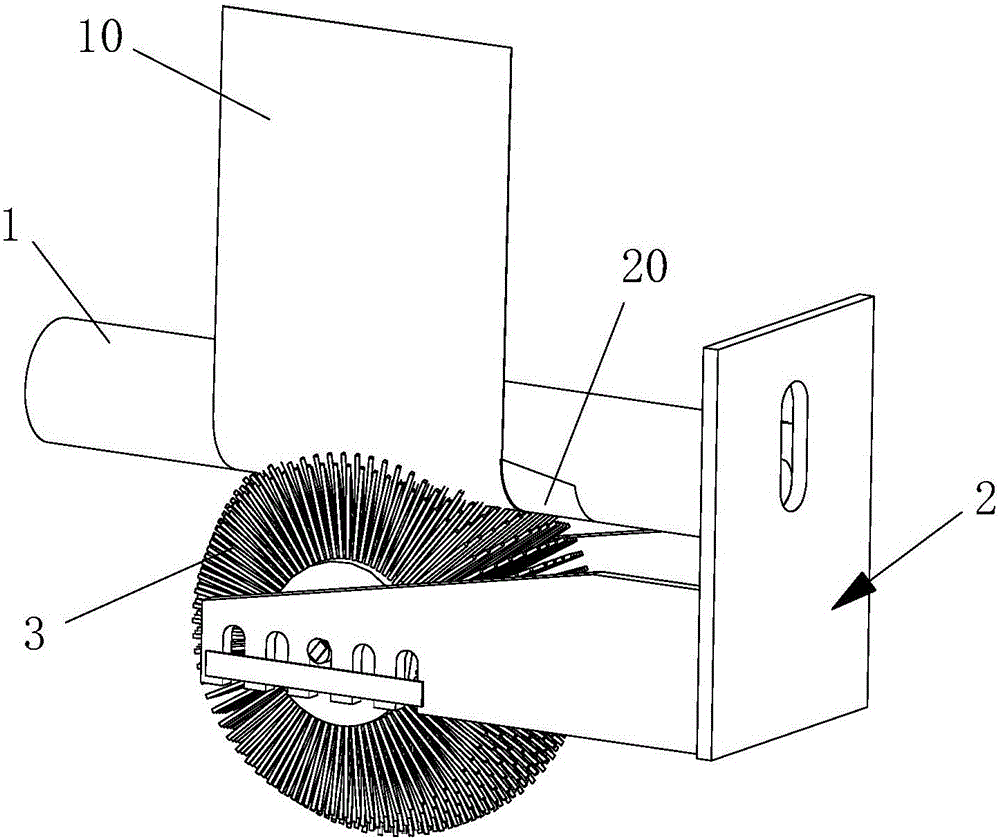

Pole lug leveling device

A technology of tabs and mounting plates, which is applied in the direction of machining/deformation, can solve the problems of increasing the tearing and falling off of tabs, affecting the utilization rate of workshop space, and increasing the size of equipment, so as to improve production efficiency and yield, Avoid the effect of broken belt or tab falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

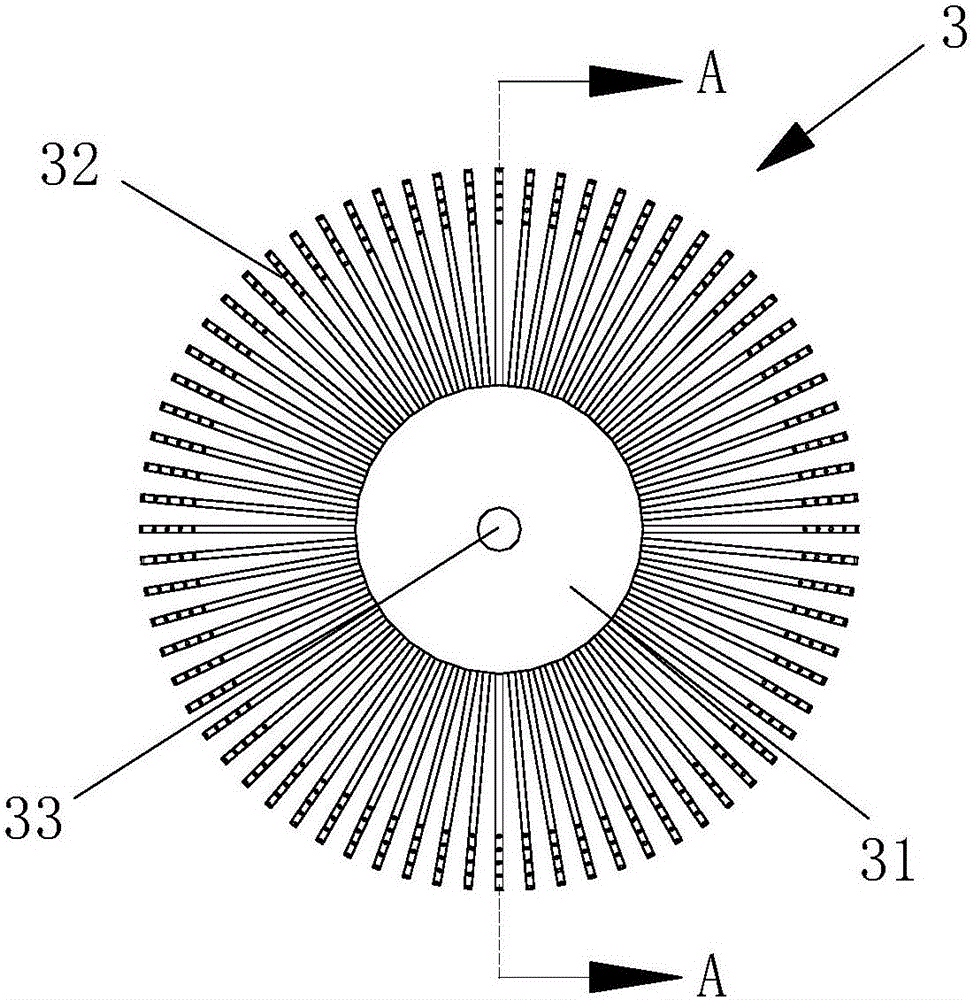

Method used

Image

Examples

Embodiment 1

[0023] A laser tab forming machine is used to make 300m positive pole pieces, and a tab smoothing device is installed on the roller of the laser tab forming machine. The operating speed of the equipment is 120mm / s, and the number of tape breaks during the production process is counted. in Table 1.

Embodiment 2

[0030] The positive and negative pole pieces (300 pieces each) are wound by a fully automatic winding machine equipped with a tab smoothing device on the idler roller. Both the positive and negative pole pieces are formed by laser tabs, and the incoming pole pieces are folded without tabs. Wrinkle situation, the winding speed is 60s / pcs, and the number of cores produced is listed in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com