Polystyrene mixing buffer system

A buffer system and polystyrene technology, which is applied in the field of equipment for making EPS extruded sheets, can solve the problems of difficult to observe the material condition, increase the spraying and stirring time, and cannot buffer the expansion stress, etc., so as to achieve the control of humidity. , Conducive to ventilation and drying, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

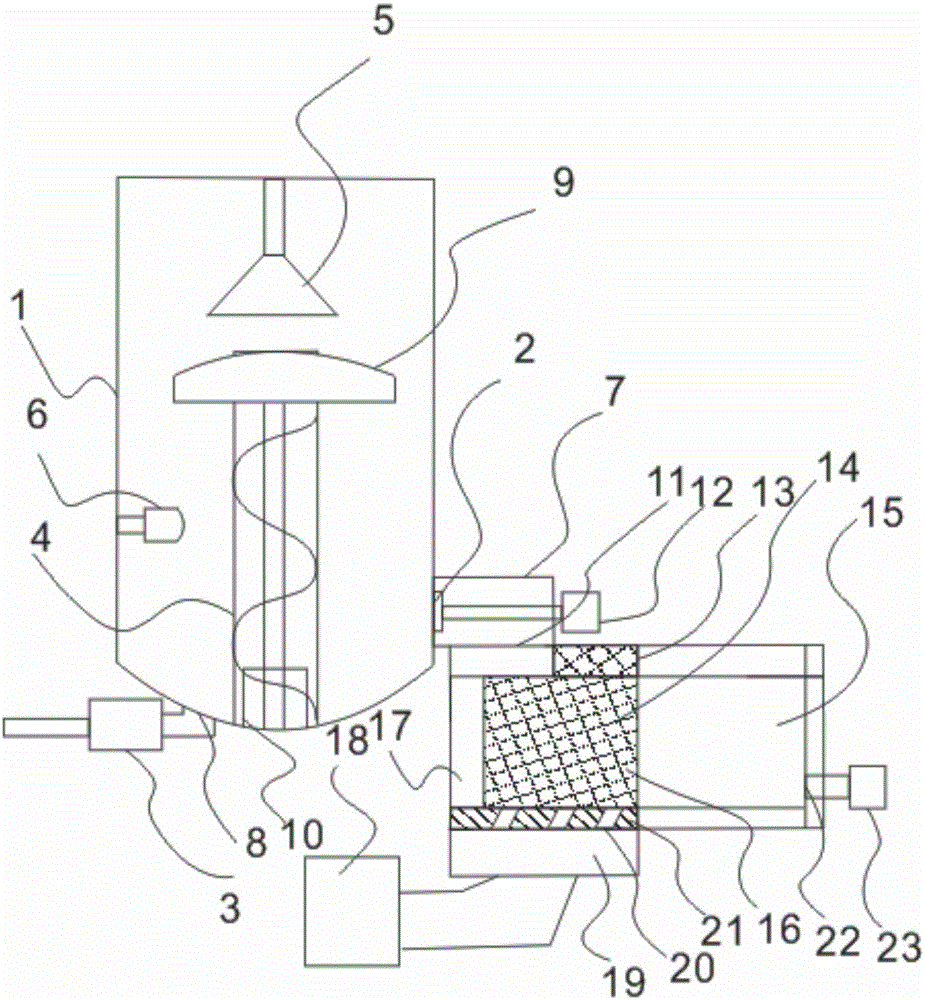

[0010] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0011] As shown in the figure, a polystyrene mixing buffer system includes a mixing tank 1 provided with a feed inlet 8 and a discharge outlet 2, an automatic spray device and a blanking bin, and the automatic spray device is located at the stirring tank 1. In the tank 1, the blanking bin is arranged below the outlet 2 of the mixing tank, the feeding port 8 of the mixing tank is arranged at the bottom of the mixing tank 1, and the outlet 2 of the mixing tank is arranged on the side of the mixing tank 1 , the bottom surface of the stirring tank 1 is a slope structure with high surroundings and low middle, the inner middle of the stirring tank 1 is provided with a lifting auger 4, and the bottom of the lifting auger 4 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com