Guide method for online negative deviation control in steel machining process

A technology of processing and negative deviation, which is applied in the direction of rolling mill control devices, metal processing equipment, metal rolling, etc., can solve the problems of fine guidance that cannot be negative deviation, profit loss, batch scrap steel, etc., and achieve timely guidance and control accuracy High, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

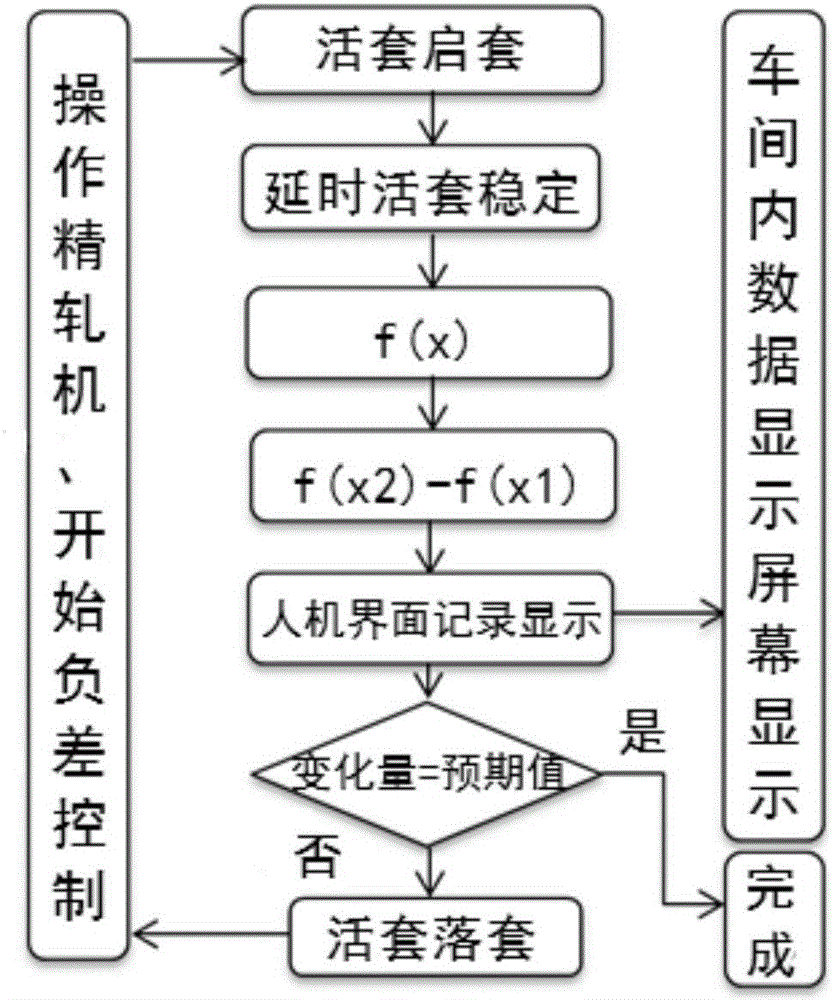

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

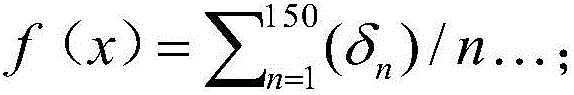

[0033] An online negative deviation control guidance method in the steel processing process of the present invention is based on the following principles:

[0034] In an ideal state, the second flow through each finishing mill is equal, that is, c=c 0 ;

[0035] get negative difference

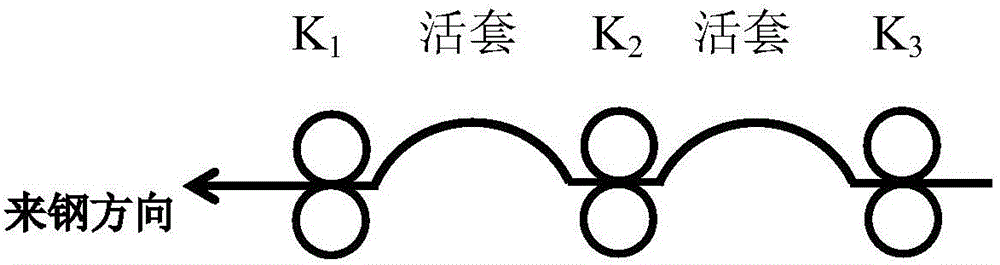

[0036] In the continuous rolling process of steel, in order to ensure that the external dimensions of the steel are qualified, and the finishing rolling realizes tension-free rolling, an automatically adjustable looper can be set between the finishing mill and the finishing mill. Its function is: To store a certain amount of metal flow between the finishing mill and the finishing mill, through automatic adjustment to ensure that there is no tension between the finishing mill and the finishing mill, and to ensure that the external quality of the steel is q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com