Preparation of sulfur and nitrogen co-doped three-dimensional graphene/manganese sulfide composite material and application of composite material in electrocatalytic reduction of oxygen

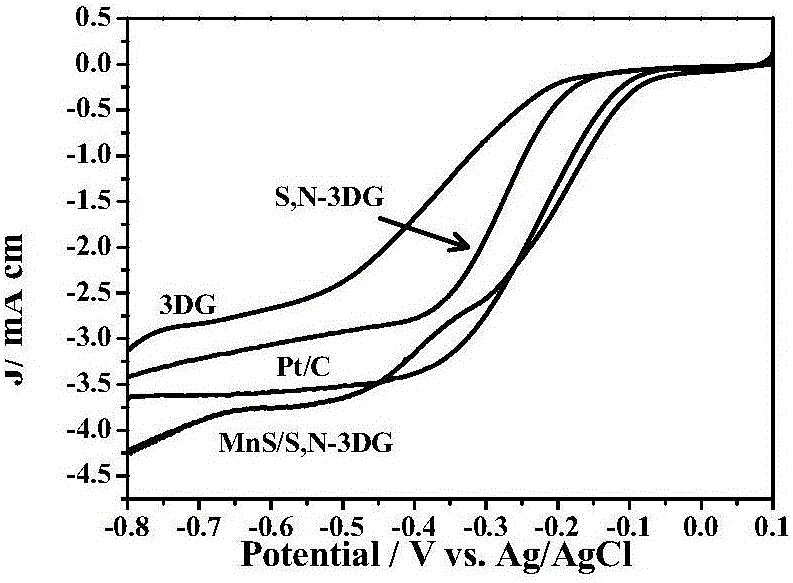

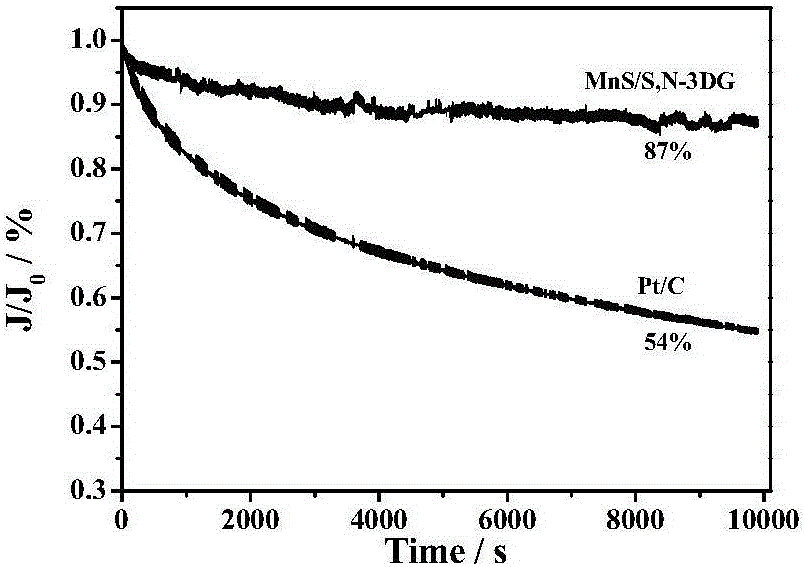

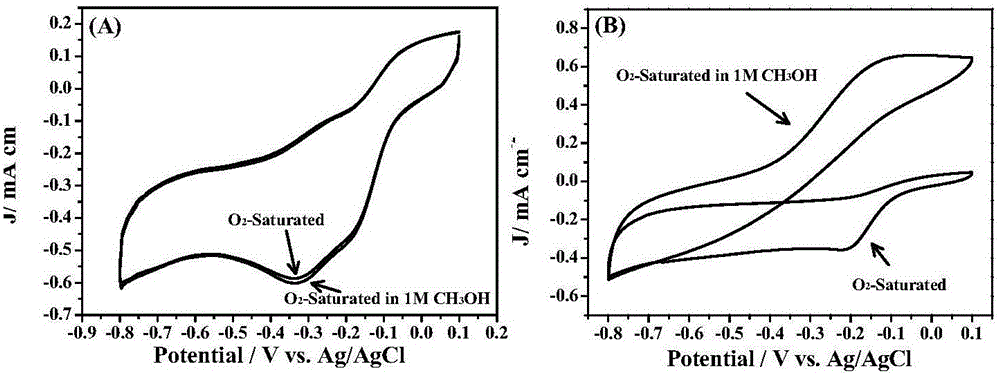

A composite material and co-doping technology, applied in the field of electrocatalytic reduction of oxygen, can solve the problems of reducing the stability of oxygen reduction catalysts, inferior oxygen reduction activity, reducing the efficiency of oxygen reduction reaction, etc. The method is simple and easy to implement, and the effect of good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation of sulfur and nitrogen co-doped three-dimensional graphene / manganese sulfide (MnS / S,N-3DG) composites and its application in the electrocatalytic reduction of oxygen includes the following steps:

[0021] (1) Preparation of MnS / S, N-3DG composite material: take 30mg of graphene oxide and ultrasonically disperse it in 15ml of water to form 2mg ml -1 graphene aqueous solution. Add 0.9 g of thiourea and 0.09 g of manganese chloride into the graphene aqueous solution, stir for 30 min and mix well. After transferring the above solution into the reaction kettle, the reaction kettle was placed in a muffle furnace, the temperature was raised to 180°C, and the temperature was kept at a constant temperature for 12 hours. The graphene oxide in the reaction kettle was transformed into graphene hydrogel, and the MnS and unreacted thiourea are attached to the surface of graphene hydrogel. The graphene hydrogel was freeze-dried for 24 hours, placed in a tube furnace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com