A preparation method of ginkgo whole powder with reduced content of ginkgo phenol and ginkgolic acid

A technology of ginkgolic acid and ginkgolic acid, which is applied in the field of preparation of ginkgo whole powder, can solve the problems of reducing ginkgolic acid and the limited degree of degradation of gingkgolic acid, and achieves the reduction of ginkgolic acid and ginkgolic acid content, enhancing food safety, and operating equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

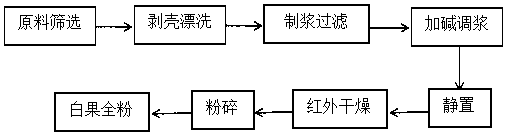

Image

Examples

experiment example 1

[0027] The mensuration of experimental example 1 ginkgol and ginkgolic acid content

[0028] Sample preparation: Accurately weigh 15.0 g of ginkgo powder, add 230 mL of petroleum ether and extract in a Soxhlet extractor at 85°C for 12 hours, and concentrate the extract under reduced pressure to dryness to obtain a yellow extract. Use a small amount of petroleum ether to dissolve the extract and load it on silica gel column chromatography for separation and purification. The eluent is chloroform: ethyl acetate: formic acid=95:5:2 (V / V / V), and ginkgol and ginkgolic acid are collected respectively After the fraction was evaporated to dryness, the methanol was fixed to a volume in a 5ml volumetric flask to obtain a sample solution. Filter the sample solution with a 0.22 μm syringe filter before HPLC quantitative analysis, and set aside.

[0029] The detection conditions of HPLC-UV-FLD are: chromatographic column: Cosmosil 5C18-MS-Ⅱ (4.61ID×250mm); methanol-1% acetic acid aqueous ...

Embodiment 3

[0037] Example 3 Infrared Drying Preparation of Ginkgo Whole Powder

[0038] Preparation method: Shell the selected ginkgo fruit, rinse in the sink, spread the clean ginkgo fruit on a bamboo sieve and drain for 1.5 hours; crush the drained ginkgo fruit into a slurry, and filter it with a 40-mesh filter; measure the initial concentration of the fresh ginkgo pulp The moisture content is 53±2%. Take 40g of ginkgo pulp, heat it at an infrared temperature of 80°C, and dry it for 40 minutes. The dried ginkgo pulp is crushed to obtain dried ginkgo powder.

[0039] Experimental results: the dried ginkgo sample was light yellow, and the edges of a small amount of ginkgo pulp appeared burnt yellow. When the infrared temperature is 80℃, the MR value (moisture ratio) of ginkgo fruit drops from 1 to below 0.01, and it takes 40 minutes. Ginkgo whole powder was pulverized after drying, and 15.0g ginkgo whole powder sample was taken, and according to the method of Example 1, the content of g...

Embodiment 4

[0043] Example 4 Preparation of ginkgo powder 2 by adding alkali to pulp + infrared drying

[0044] Preparation method: Shell the selected ginkgo fruit, rinse in the sink, spread the clean fresh ginkgo fruit on a bamboo sieve and drain for 1.5 hours; crush the drained ginkgo fruit into a slurry, filter with a 40-mesh filter; measure the fresh ginkgo pulp The initial moisture content is 53±2%; with 0.08g Na 2 CO 3 40 g of ginkgo pulp was mixed for 4 hours, then the ginkgo pulp was placed at an infrared temperature of 60° C., and dried for 75 minutes; crushed to obtain ginkgo powder.

[0045] Experimental results: The dried ginkgo sample is yellow and has a fragrance. The content of ginkgolic acid in dried ginkgo whole powder detected by HPLC-UV-FLD was 1.9×10 -5 mg / mg, the content of ginkgo biloba is 6.3×10 -7 mg / mg. Compared with hot-air dried ginkgo whole powder, the contents of ginkgolic acid and ginkgol decreased by 43.3% and 84.8%, respectively, and compared with the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com