Cereal baking and storing as well as regulating integrated barn provided with air boxes internally and interlayer externally

An integrated, grain-based technology, applied in the field of grain storage bins, can solve problems such as uneven drying, easy "condensation on the grain surface, short drying time, etc., to prevent blockage or short circuit of the wind network, facilitate storage, and have small wind network resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

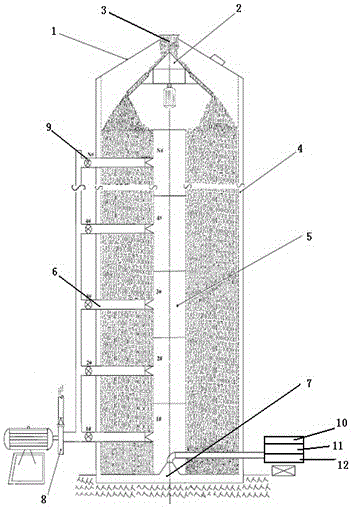

[0008] Such as figure 1 As shown, the present invention includes an integrated warehouse 1, a grain distribution device 2, an outer compartment 4 of an integrated warehouse, an inner bellows 5 of an integrated warehouse, a heating device 10, a refrigeration device 11, a humidifying device 12, an air volume distribution device 7, a centrifugal fan 8, The air volume control valve 9 is provided with a grain feeding port 3 at the top of the integrated warehouse, a grain distribution device 2 is arranged at the lower end of the grain feeding port 3, several layers of inner bellows 5 are arranged in the middle of the integrated warehouse, and outer compartments are arranged around the integrated warehouse 4. A heating device 10, a refrigeration device 11, and a humidifying device 12 are arranged outside the integrated warehouse, and are connected to the air volume distribution device 7 through pipes. The integrated warehouse 1 is provided with several suction pipes 6 from top to bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com