Exhaust gas treatment apparatus and exhaust gas treatment method for internal combustion engine

An exhaust gas treatment device and a technology for exhaust gas treatment, which are applied to the electronic control of the exhaust gas treatment device, the diagnosis device of the exhaust gas treatment device, and the exhaust device, etc., can solve the problem of ineffective catalytic converter purification performance, etc. Reduce the effect of inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

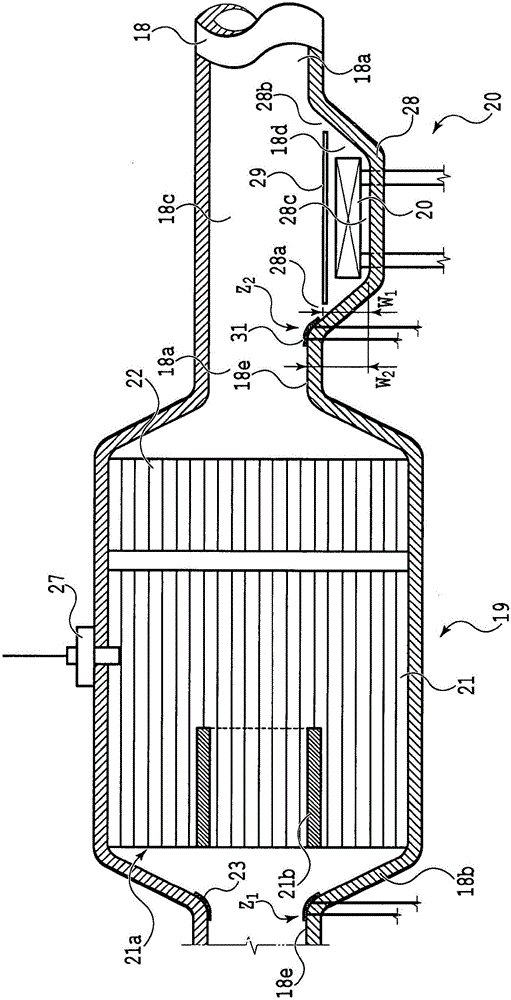

[0063] refer to Figure 1 to Figure 9 One embodiment in which the disclosure of the present application is applied to a vehicle equipped with a compression ignition multi-cylinder internal combustion engine will be described in detail. However, the disclosure of the present application is not limited to such an embodiment, and the structure disclosed in the present application can be freely changed according to the required characteristics. For example, the disclosure of the present application is also effective for an internal combustion engine of a spark ignition system that uses gasoline, alcohol, LNG (liquefied natural gas) or the like as fuel and ignites the fuel with a spark plug.

[0064] exist figure 1 The main part of the engine system in this embodiment is schematically shown in figure 2 The control frame of the above-mentioned main part is roughly represented in . In addition, in figure 1 In FIG. 2 , as an auxiliary machine of the engine 10 , a general exhaust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com