A scr injection system

An injection system and nozzle technology, applied in the direction of machine/engine, mechanical equipment, engine components, etc., can solve the problems of large volume, complex system and high application difficulty of diaphragm pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

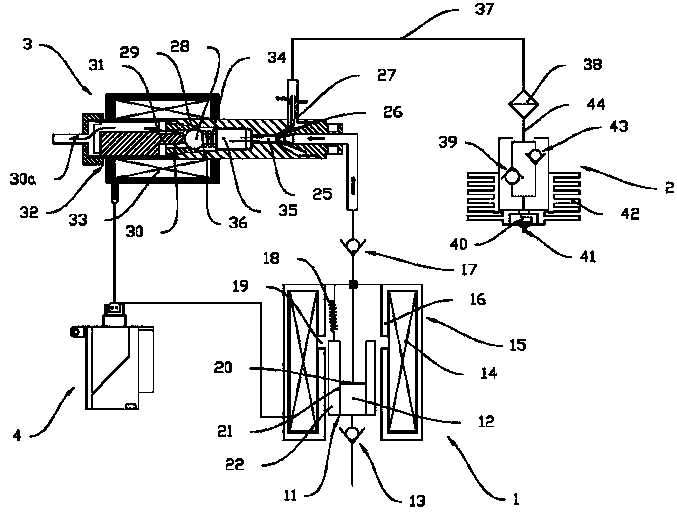

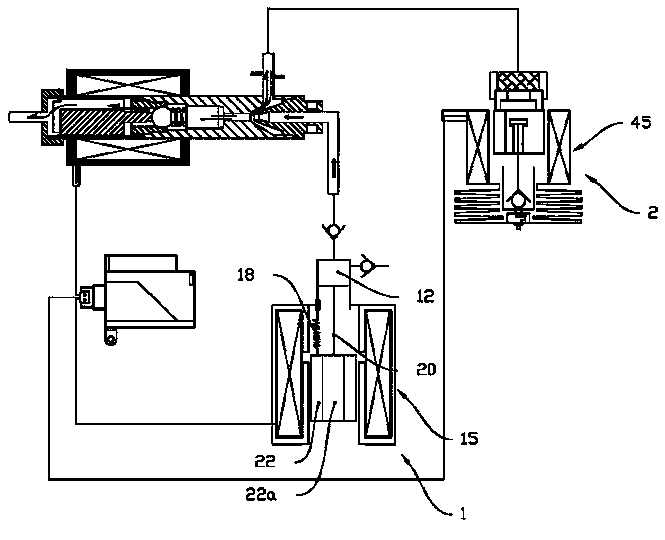

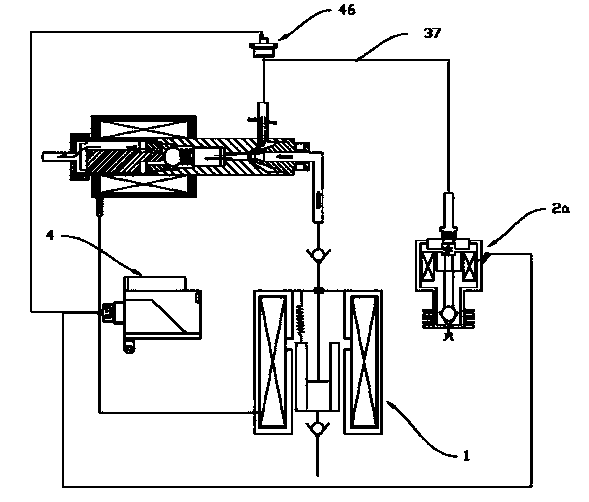

[0042] Such as figure 1 As shown, it is one of the schematic diagrams of the structure of the SCR injection system provided by the present invention, which includes a pulse pump 1, a nozzle 2, an injection vacuum device 3 and a controller 4 for giving driving signals. The pulse pump 1 receives the pulse signal of the controller 4 to generate pressurized fluid, which provides a jet source for the nozzle 2 and the injection vacuum device 3.

[0043] The pulse pump 1 is a sleeve-piston structure, including an electromagnetic device 15 and a plunger pump assembly 11 . Among them, the plunger pump assembly 11 includes a sleeve 21, a plunger 20, a return spring 18, an inlet valve 13 and an outlet valve 17, the sleeve 21 and the plunger 20 are closely matched to form a pressure delivery volume 12, and the return spring 18 acts on the sleeve 21. The electromagnetic device 15 includes a solenoid 14 , a yoke 16 , a magnetic gap 19 and an armature 22 . The armature 22 and the sleeve 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com