Molecular sieve composite material having core-shell structure, preparation method and application thereof

A composite material and molecular sieve technology, which is applied in the preparation of inorganic composite materials, has the field of preparation of alumina and molecular sieve composite materials, and achieves the effects of easy modulation and chemical modification, and simple and easy preparation procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] A preparation method of a molecular sieve composite material with a core-shell structure, the preparation method comprising:

[0049] Step 1: mixing the microporous molecular sieve and deionized water, adjusting the pH to 3-8 with acid, preparing a microporous molecular sieve slurry after beating, and controlling the solid content of the prepared microporous molecular sieve slurry to 10-60wt%;

[0050] Step 2: Mix and beat the mesoporous alumina molecular sieve with water, adjust the pH value of the system to 1.5-5 with acid, and prepare the mesoporous alumina molecular sieve peptizing slurry, and control the liquid-solid content of the prepared mesoporous alumina mucilage at 3~35wt%;

[0051] Step 3: Mix the microporous molecular sieve slurry and the mesoporous alumina glue slurry, the mass of the mesoporous alumina molecular sieve accounts for 5-50wt% of the mass of the microporous molecular sieve, stir the mixed solution at 25-50°C for 10-60min, adjust with acid The...

Embodiment 1

[0054] Embodiment 1: the synthesis of mesoporous alumina molecular sieve

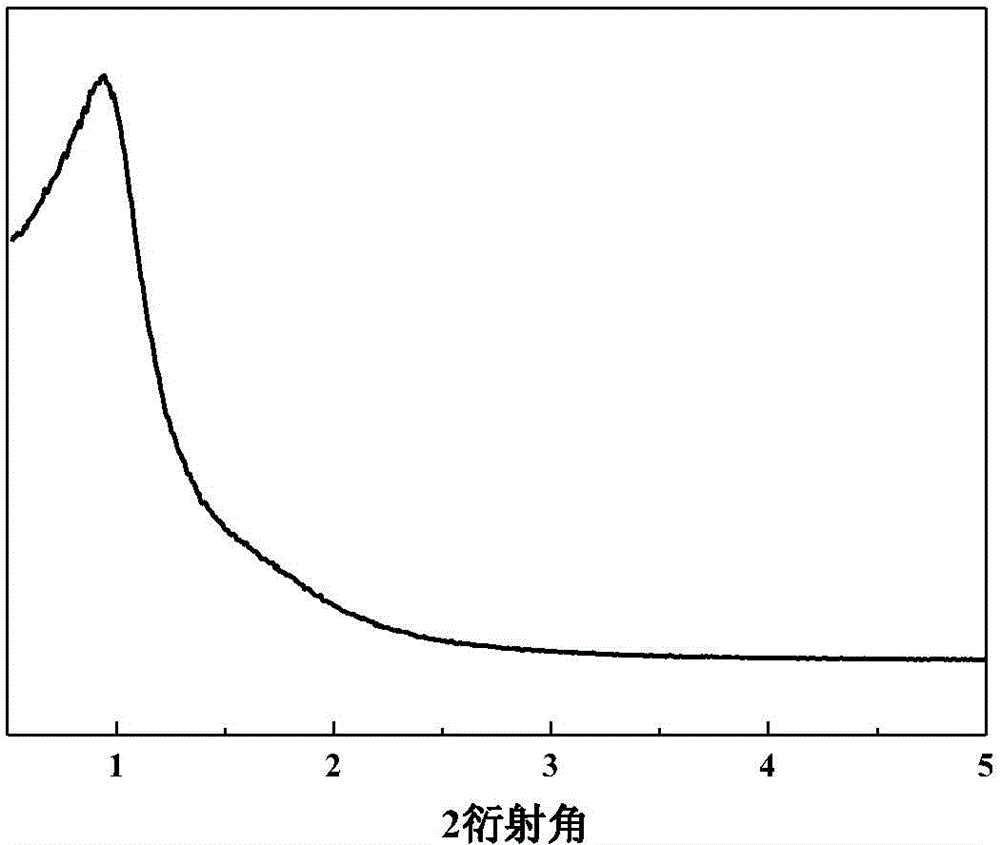

[0055] Firstly, 2.0g of template agent P123 was dissolved in 40ml of ethanol, and stirred continuously at room temperature for 2h. Add 5.6ml of concentrated nitric acid and 2.04g of aluminum isopropoxide (10mmol), and stir the reaction at room temperature for 5h. The obtained solution was aged in an oven at 60° C. for 48 h. The obtained bright yellow solid was calcined in a muffle furnace at 700° C. for 4 h to obtain a white solid powder sample. see figure 1 , it can be seen from the figure that the prepared sample has a sharp diffraction peak around 0.9°, which is the characteristic diffraction peak of the ordered mesoporous alumina molecular sieve, indicating that the sample has a long-range ordered one-dimensional hexagonal mesoporous channel structure, which is consistent with The results reported in the literature are consistent.

Embodiment 2

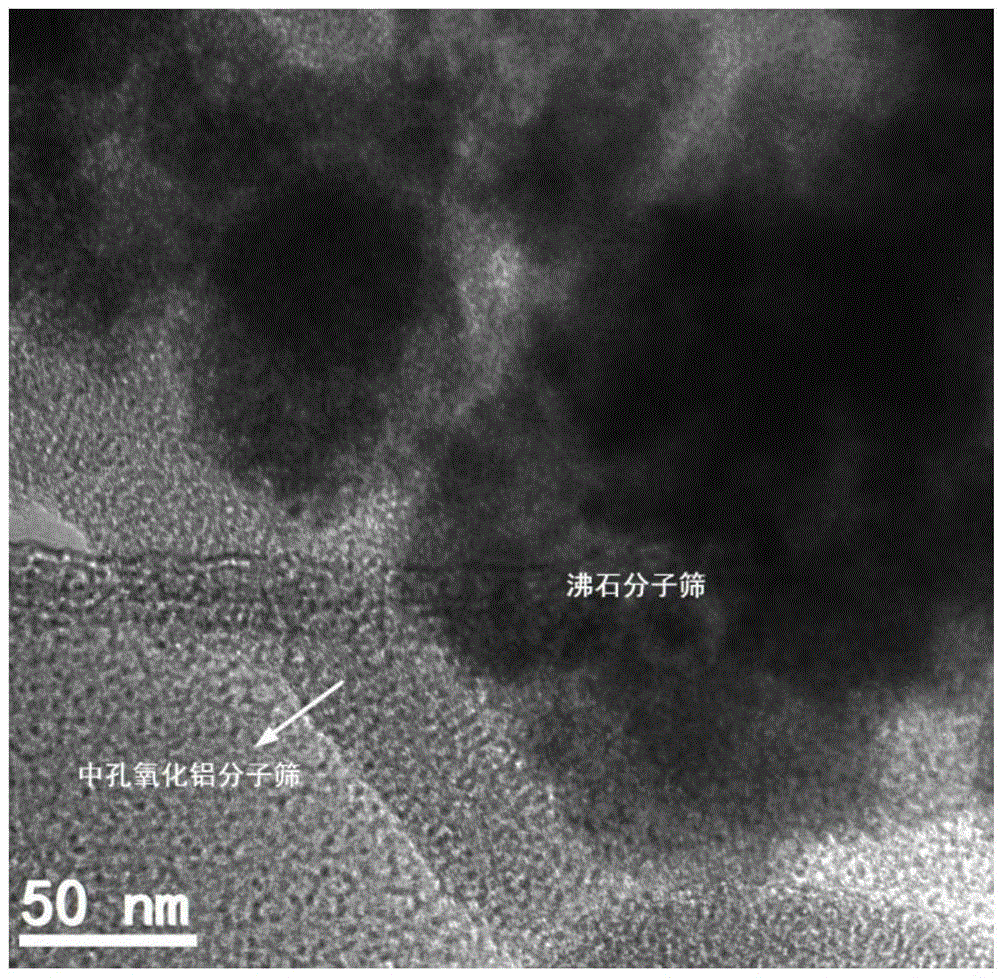

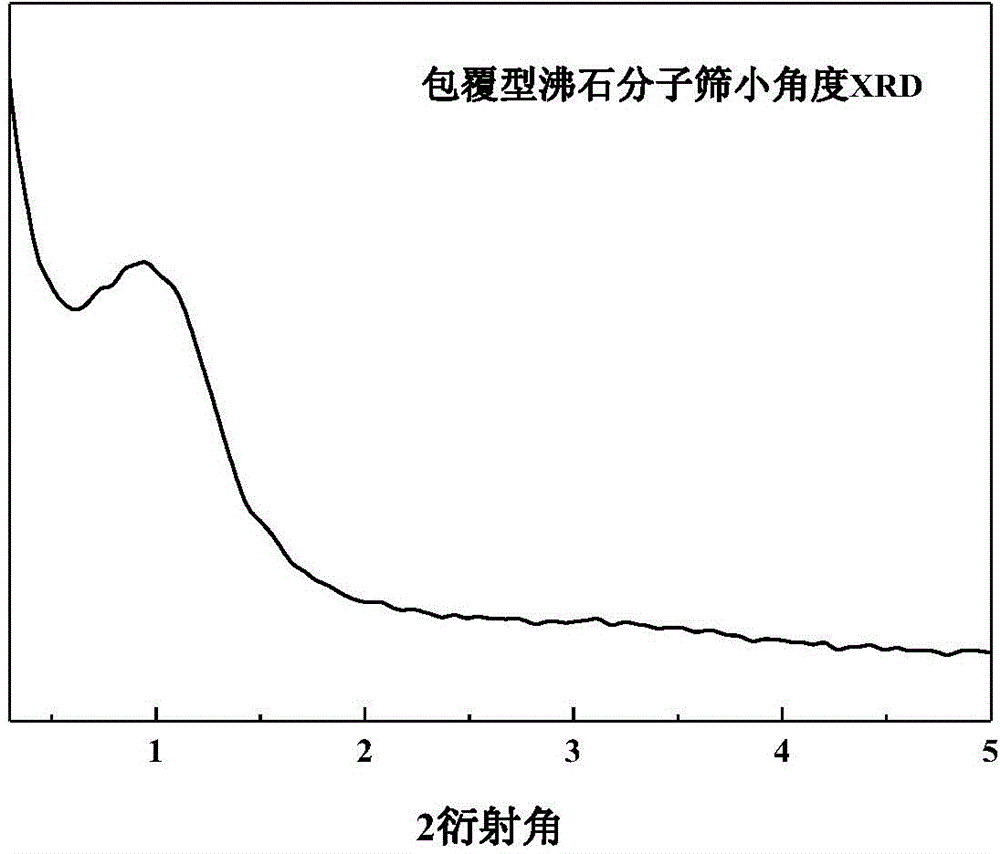

[0056] Example 2: Preparation of ZSM-5 molecular sieve composite material coated with mesoporous alumina molecular sieve

[0057] (1) step: mix the ZSM-5 molecular sieve with a solid content of 30wt% and an appropriate amount of deionized water, adjust the pH to about 5 with hydrochloric acid, and prepare a ZSM-5 molecular sieve slurry after beating.

[0058] (2) step: mix the mesoporous alumina molecular sieve synthesized in Example 1 with a solid content of 15wt% and metered deionized water, adjust the pH of the system with hydrochloric acid to be about 3, and prepare mesoporous alumina molecular sieve peptization after beating slurry.

[0059] (3) Step: Take by weighing an appropriate amount of mesoporous alumina molecular sieve glue solution and ZSM-5 molecular sieve slurry according to the mass percentage of alumina / ZSM-5 as 30wt%, mix the two and adjust the pH value of the system to about 4 with hydrochloric acid, and then Stirring at 40°C for 30 minutes, then standing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com