Frequency compensation circuit-based white LED step-up conversion system

A frequency compensation, boost conversion technology, applied in the field of white LED boost conversion system, can solve the problem of inability to output constant current, and achieve the effect of eliminating oscillation, improving stability, and avoiding brightness changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

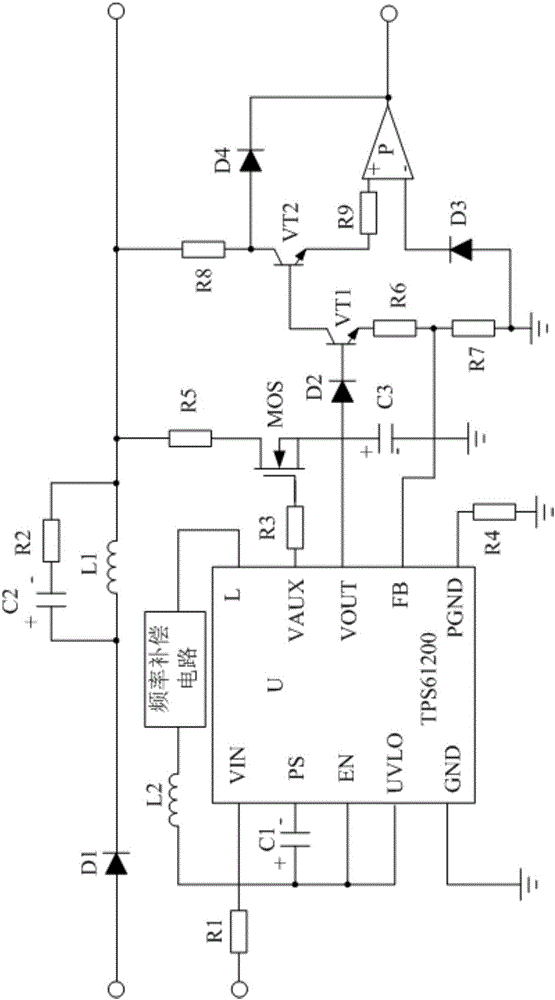

[0015] Such as figure 1 As shown, the present invention is mainly composed of a processing chip U, a constant current output circuit, a frequency compensation circuit, a diode D1, a field effect transistor MOS, a resistor R1, a resistor R2, a resistor R3, a resistor R4, a resistor R5, a capacitor C1, a capacitor C2, and a capacitor C3 is composed of inductor L1 and inductor L2.

[0016] Wherein, the constant current output circuit is connected to the VAUX pin of the processing chip U. The frequency compensation circuit is connected with the L pin of the processing chip U. One end of the inductor L1 is connected to the N pole of the diode D1, and the other end thereof is connected to the drain of the field effect transistor MOS after passing through the resistor R5. The anode of the capacitor C2 is connected to the N pole of the diode D1, and its cathode is connected to the connection point of the inductor L1 and the resistor R5 after passing through the resistor R2. The res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com