Scratch and abrasion resistant solar backboard

A solar backplane, scratch-resistant technology, applied in the field of solar modules, can solve the problems of affecting the service life of the backplane, reducing light conversion efficiency, poor tensile strength, etc., achieving simple structure, avoiding easy scratches, and improving The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

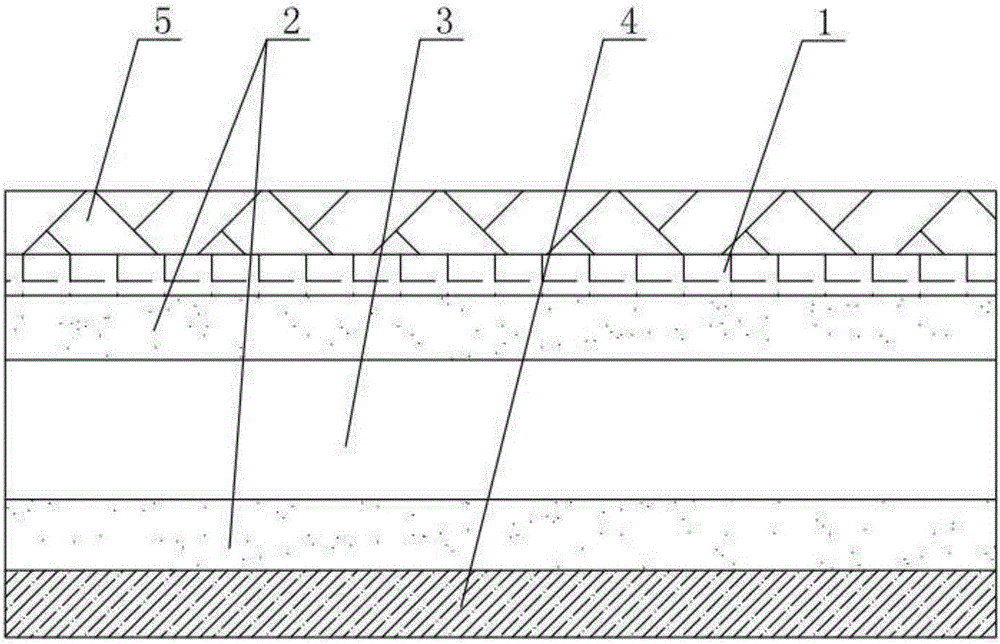

[0015] like figure 1 As shown, a scratch-resistant solar backsheet includes a PET substrate 3, one side of the PET substrate 3 is connected to the weather-resistant layer 1 through the adhesive layer 2, and a scratch-resistant and wear-resistant coating 5 is arranged on the upper surface of the weather-resistant layer. The other end of the PET substrate 3 is connected to the weather-resistant adhesive layer 4 through the adhesive layer 2; the scratch-resistant and wear-resistant coating 5 is a fluororesin coating modified by a highly dispersed nanoporous gas phase SIO2 material, and the fluororesin coating is poly Vinylidene fluoride, polychlorotrifluoroethylene, polytetrafluoroethylene or copolymers of tetrafluoroethylene and ethylene. The above-mentioned anti-scratch and wear-resistant coating 5 has a thickness of 1-30 μm. The thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com