A mechanical shock absorber

A technology of mechanical shock absorption and hydraulic shock absorption, which is applied in the direction of shock absorbers, mechanical equipment, springs/shock absorbers, etc., can solve the problems of poor shock absorption effect, inconvenient installation, large amount of wear, etc., and achieve safe use Performance, easy installation and disassembly, good shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The content of the present invention will be described below in conjunction with specific embodiments.

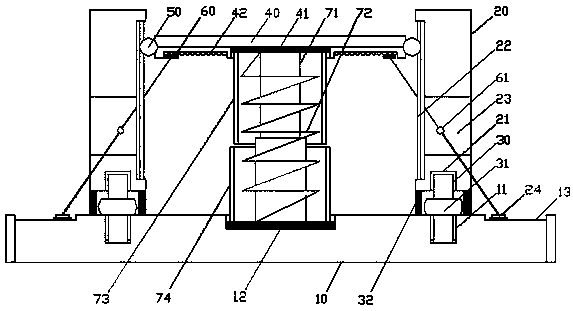

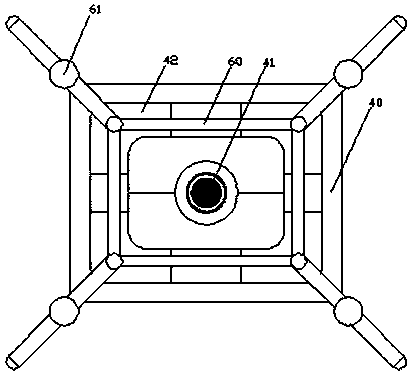

[0021] Such as Figure 1 to Figure 5 Shown is a structural schematic diagram of a mechanical damping device according to the present invention.

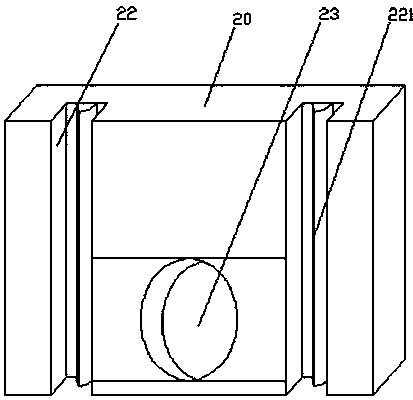

[0022] A mechanical damping device according to the present invention comprises a base 10 and two sets of damping baffles 20, the two sets of damping baffles 20 are arranged in parallel on both sides of the end face of the base 10, and several groups of No. 1 fixing screws are processed on both sides of the end face of the base 10. Holes 11 and the bottom of the damping partition 20 are all processed with a number of No. 2 fixing screw holes 21 used in conjunction with the No. 1 fixing screw hole 11, and the No. 1 fixing screw hole 11 and the No. 2 fixing screw hole 21 are provided with a connection base 10 and a damping partition. The connecting threaded rod 30 of the plate 20 is provided with an adjusting nut 31 for adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com