Anti-slip assembly

An anti-slip and component technology, applied in the mechanical field, can solve problems such as equipment stoppage and work-related injuries, and achieve the effects of flexible and convenient use, high self-stability, and good anti-slip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

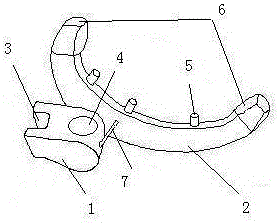

[0016] Such as figure 1 As shown, an anti-slip assembly includes a main part 1 and an accessory 2, and through the cooperation of the two, sufficient stability is ensured. Wherein, the main part 1 and the accessory 2 are fixed by welding, and the welding method is simple and easy to realize, and has high firmness. One end of the main part 1 is provided with a slot 3, and the other end of the main part 1 is provided with a tapered hole 4 whose diameter gradually decreases. The diameter of the tapered hole 4 gradually decreases from top to bottom, and the slot 3 and the tapered hole 4 are arranged along the height direction of the main part 1, and are distributed side by side at both ends of the main part 1. Through the mutual cooperation between the slot 3 and the tapered hole 4, it is ensured that the main part 1 is connected with the adjacent parts. Self-stability i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com