High-strength water-permeable plastic-wood floor board

A high-strength, plastic-wood technology, applied in the direction of floor, covering/lining, construction, etc., can solve the problem that the floor is not as flat as the room, the tenon is broken, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

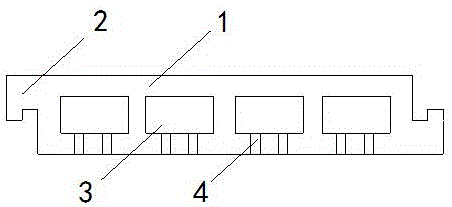

[0009] like figure 1 The shown high-strength permeable plastic wood flooring comprises a rectangular parallelepiped body 1, and two sides of the body 1 are provided with 7-shaped bumps 2, and the bumps 2 on both sides are respectively connected with the top and bottom of the body 1, and When the adjacent plastic wood floors are spliced, the adjacent protrusions 2 are engaged with each other; a group of cavities 3 are provided in the middle of the board body 1, and a water hole 4 is provided between the cavity 3 and the bottom of the board body 1. The water hole 4 The diameter of 4 is not greater than 0.5cm, and the shape of the cavity 3 is a rectangle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com