A construction method for main girder side-span closure for composite girder cable-stayed bridges

A construction method and side-span technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of three-way consolidation system design and construction difficulties, concrete construction quality is difficult to guarantee, and construction technology is complicated, etc., to achieve reduction Minimize the interference of external environmental factors, ensure the construction quality, and ensure the effect of accurate docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] pass below Figure 1 to Figure 8 And the way of enumerating some optional embodiments of the present invention, the technical solution of the present invention (including the preferred technical solution) is described in further detail, and any technical feature and any technical solution in this embodiment do not limit the protection scope of the present invention .

[0033] The main girder side-span closure construction method for the combined girder cable-stayed bridge designed by the present invention comprises the following steps:

[0034] 1) Set up a support slideway system in the area of the end beam section. The support slideway system includes a steel pipe support device and a slideway device:

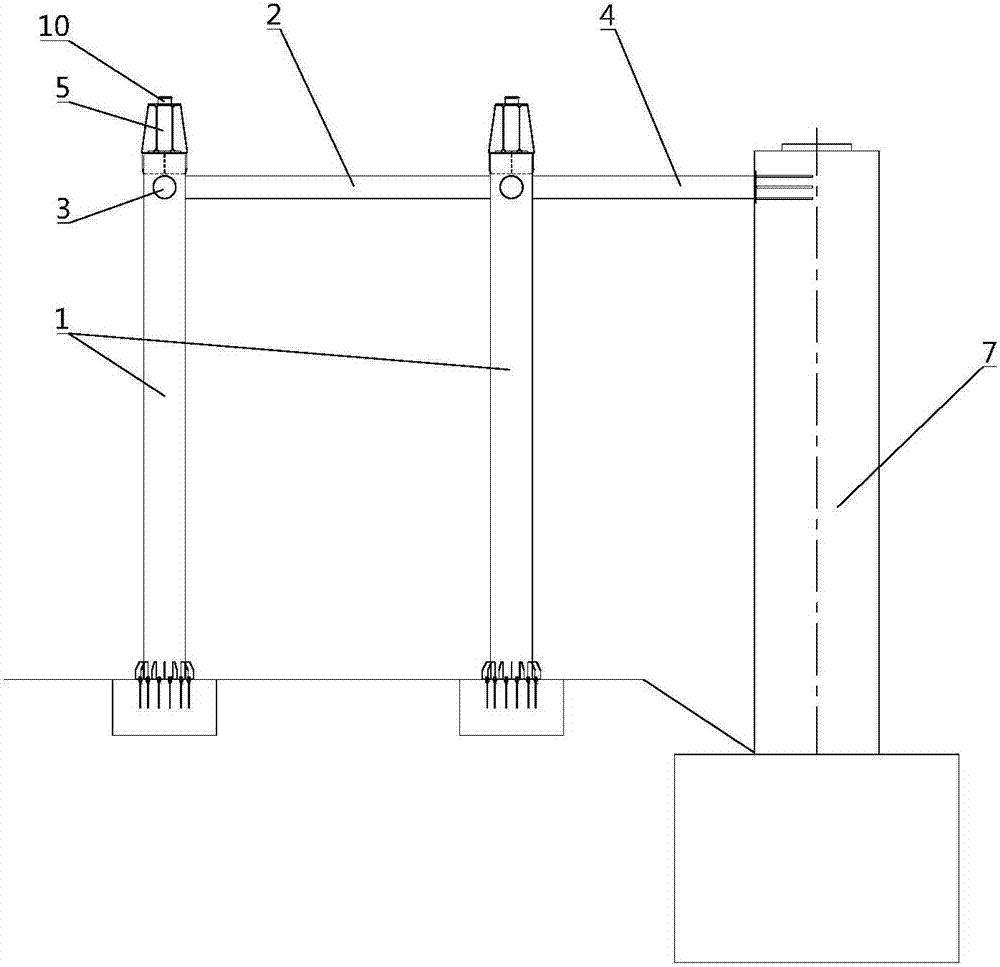

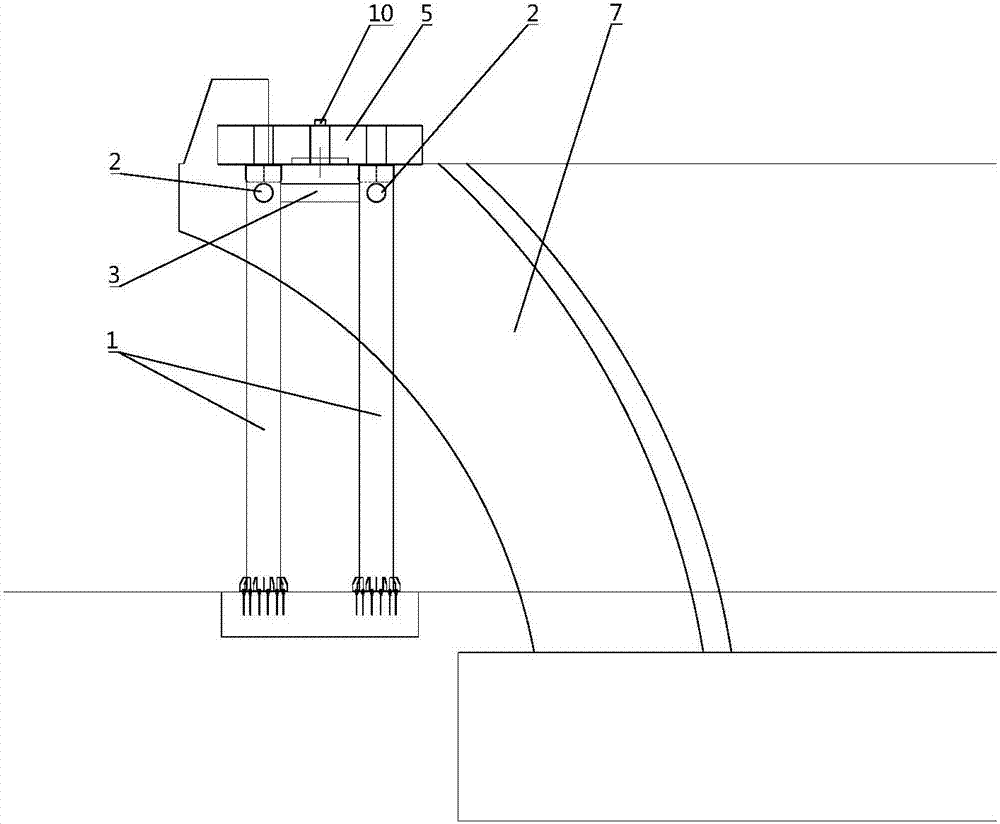

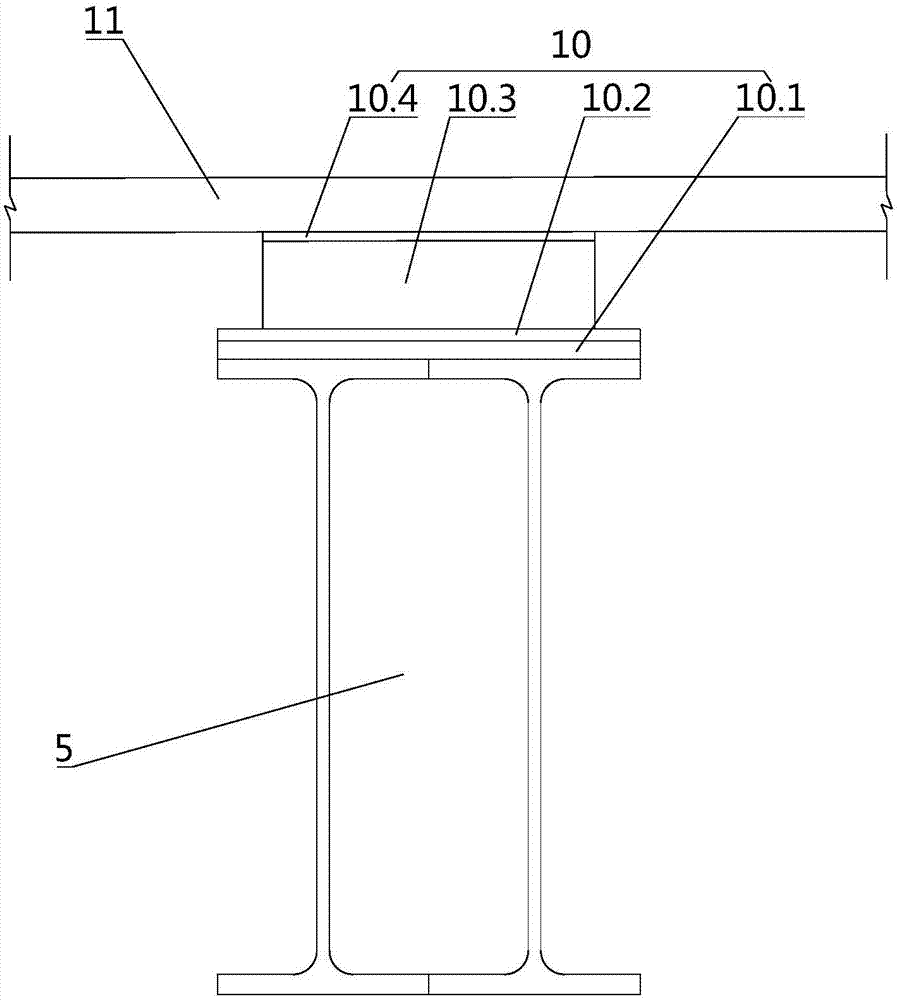

[0035] ①Establish the steel pipe support device, the steel pipe support device includes steel pipe column 1, the first parallel joint 2, the second parallel joint 3 and the third parallel joint 4, such as figure 1 and figure 2 As shown: a plurality of vertically a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com