Titanium carbide-zirconium carbide high-temperature solar selective absorbing coating and preparation method thereof

A technology of absorbing coating and zirconium carbide, which is applied in the fields of titanium carbide-zirconium carbide high-temperature solar selective absorbing coating and its preparation, high-temperature solar selective absorbing coating and its preparation, and can solve the problem of optical performance degradation, failure, metal Particle oxidation, diffusion, agglomeration and other problems to achieve the effect of improving absorption rate, convenient operation and excellent high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

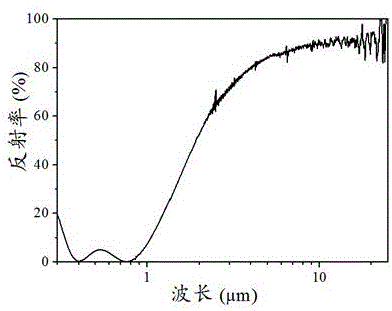

[0021] A titanium carbide-zirconium carbide high-temperature solar selective absorption coating comprises a heat absorber base, an absorber layer and an anti-reflection layer from the bottom layer to the surface in sequence; the heat absorber base is a polished stainless steel sheet or a copper sheet. The absorbing layer material is a composite of titanium carbide and zirconium carbide, which is prepared by double-target co-sputtering, in which titanium carbide is prepared by DC magnetron sputtering, and zirconium carbide is prepared by radio frequency magnetron sputtering; the absorbing layer is composited The thickness of the material is 35 nm, and the atomic percentage of zirconium in the absorbing layer composite is 0.5%. The material of the anti-reflection layer is aluminum oxide, which is prepared by radio frequency magnetron sputtering, with a thickness of 60 nm.

[0022] The preparation method of the above-mentioned titanium carbide-zirconium carbide high temperature s...

Embodiment 2

[0028]A titanium carbide-zirconium carbide high-temperature solar selective absorption coating comprises a heat absorber base, an absorber layer and an anti-reflection layer from the bottom layer to the surface in sequence; the heat absorber base is a polished stainless steel sheet. The absorbing layer material is a composite of titanium carbide and zirconium carbide, which is prepared by double-target co-sputtering, in which titanium carbide is prepared by DC magnetron sputtering, and zirconium carbide is prepared by radio frequency magnetron sputtering; the absorbing layer is composited The thickness of the material is 80 nm, and the atomic percentage of zirconium in the absorbing layer composite is 3%. The material of the anti-reflection layer is aluminum oxide, which is prepared by radio frequency magnetron sputtering, with a thickness of 30 nm.

[0029] The preparation method of the above-mentioned titanium carbide-zirconium carbide high temperature solar energy selective...

Embodiment 3

[0035] A titanium carbide-zirconium carbide high-temperature solar selective absorption coating comprises a heat absorber base, an absorber layer and an anti-reflection layer from the bottom layer to the surface in sequence; the heat absorber base is a polished stainless steel sheet. The absorbing layer material is a composite of titanium carbide and zirconium carbide, which is prepared by double-target co-sputtering, in which titanium carbide is prepared by DC magnetron sputtering, and zirconium carbide is prepared by radio frequency magnetron sputtering; the absorbing layer is composited The thickness of the material is 55 nm, and the atomic percentage of zirconium in the absorbing layer composite is 0.83%. The material of the anti-reflection layer is aluminum oxide, which is prepared by radio frequency magnetron sputtering, with a thickness of 46 nm.

[0036] The preparation method of the above-mentioned titanium carbide-zirconium carbide high temperature solar energy selec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com