Eco-friendlyceramic tilegum for vitrified tiles

An environment-friendly, vitrified brick technology, applied in the direction of adhesives, adhesive types, conjugated diene adhesives, etc., can solve the problems of poor self-defense water penetration, poor frost resistance, and low bonding strength, and achieve Long-term care, long life, excellent acid and alkali resistance, and excellent anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

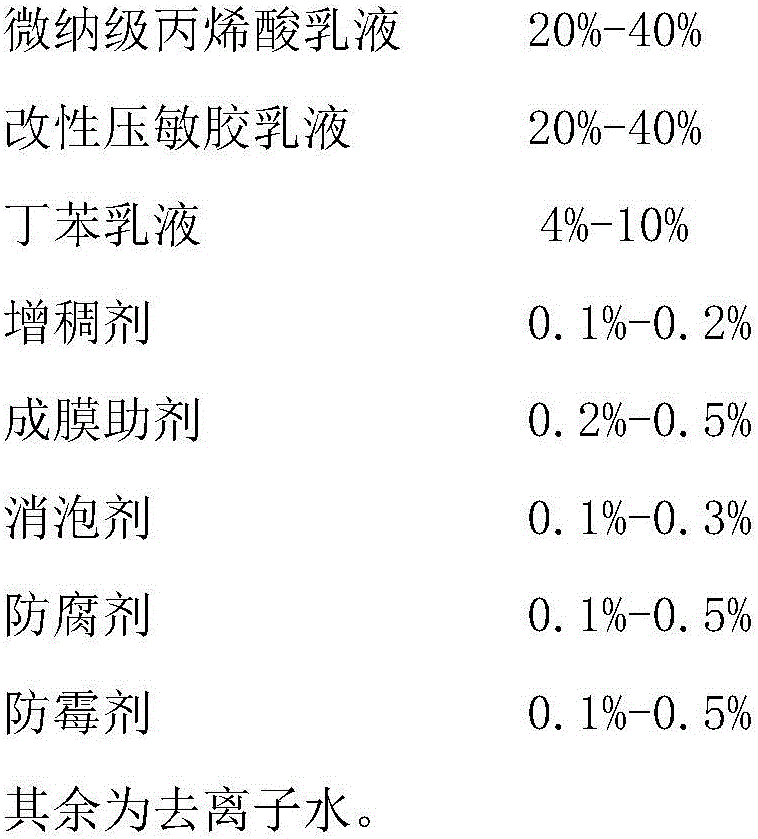

[0011] The present invention proposes an ecological environment-friendly tile adhesive for vitrified tiles, which includes the following components:

[0012]

Embodiment 2

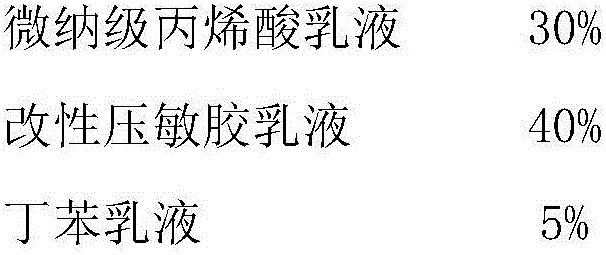

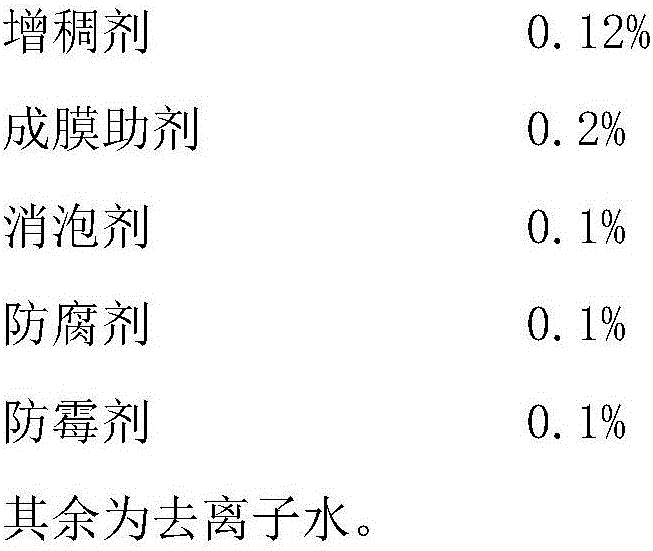

[0014] The present invention proposes an ecological environment-friendly tile adhesive for vitrified tiles, which includes the following components:

[0015]

[0016]

Embodiment 3

[0018] The present invention proposes an ecological environment-friendly tile adhesive for vitrified tiles, which includes the following components:

[0019]

[0020] The invention is a single-component product, which can be directly painted on the vitrified brick during construction, and the construction is convenient and fast.

[0021] High bonding strength, can form a new rough surface on the bonding surface of vitrified bricks, so that it can enhance the bonding ability with bonding materials; good flexibility, small hardening shrinkage, comparable to cement-based bonding materials Strong capacity, strong bonding, and other interface treatment on the back of bricks with dense texture, low water absorption and smooth surface can effectively prevent or delay the occurrence of stone lesions. The following is the test data of the embodiment:

[0022]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com