Crane anti-collision control system

A control system and anti-collision technology, applied in the direction of load hanging components, transportation and packaging, safety devices, etc., can solve the problems of insensitive mechanical limit switches, shortened equipment service life, and long braking distance of cranes. It can achieve the effect of obvious collision prevention, good braking effect and safety protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

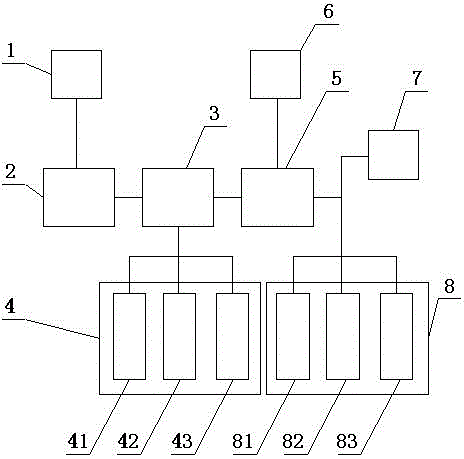

[0017] Such as figure 1 As shown, a crane anti-collision control system includes a data collector 3, the data collector 3 is connected to a parameter input device 2, and the parameter input device 2 is connected to a power supply 1, and the data collector The input end of 3 is connected with monitoring module 4, and described monitoring module 4 comprises hook height sensor 41, cart displacement sensor 42 and trolley displacement sensor 43, and the output end of described data collector 3 is connected with controller 5, The output end of the controller 5 is connected with a display 6, the controller 5 is connected with an alarm 7 and a control module 8, and the control module 8 includes a hook height control mechanism 81, a cart displacement control mechanism 82 And dolly displacement control mechanism 83.

[0018] An anti-collision control system for a crane in the present invention has an external power supply 1 for power supply. First, the safe height value of the hook, th...

Embodiment 2

[0020] Such as figure 1 As shown, a crane anti-collision control system includes a data collector 3, the data collector 3 is connected to a parameter input device 2, and the parameter input device 2 is connected to a power supply 1, and the data collector The input end of 3 is connected with monitoring module 4, and described monitoring module 4 comprises hook height sensor 41, cart displacement sensor 42 and trolley displacement sensor 43, and the output end of described data collector 3 is connected with controller 5, The output end of the controller 5 is connected with a display 6, the controller 5 is connected with an alarm 7 and a control module 8, and the control module 8 includes a hook height control mechanism 81, a cart displacement control mechanism 82 and dolly displacement control mechanism 83; described hook height sensor 41, cart displacement sensor 42 and dolly displacement sensor 43 are all radar sensors; described alarm 7 is an LED sound and light alarm; descr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com