Preparation method of gradient graphene/polyurethane conductive composite material

A conductive composite material, polyurethane technology, applied in chemical instruments and methods, layered products, fiber treatment, etc., can solve the problems that restrict the preparation and application of high-performance conductive composite materials, easy agglomeration of graphene, and clay improvement, etc., to achieve good results Mechanical properties, reduced percolation value, effect of low percolation value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of the graphene / polyurethane conductive composite material of the present embodiment, the steps are as follows:

[0029] (1) Choose DMF as the organic solvent, weigh 3g of TPU pellets, put them in 70ml of DMF solvent, and stir for 30min at a temperature of 40°C; according to the proportion of 0.2wt%, measure 1.333g of graphene in water dispersion (graphene content 0.45wt%), put it in 20ml of DMF solvent, ultrasonic for 10min; mix the two solutions, and clean the graphene DMF beaker with 10ml of DMF solution, stir and ultrasonic for 30min again; after the mixed solution is cooled, add it dropwise 500ml of methanol, to obtain flocs; filter the above-mentioned flocs, and put them in an oven to dry for 20h at 80°C to obtain graphene-containing polyurethane powder;

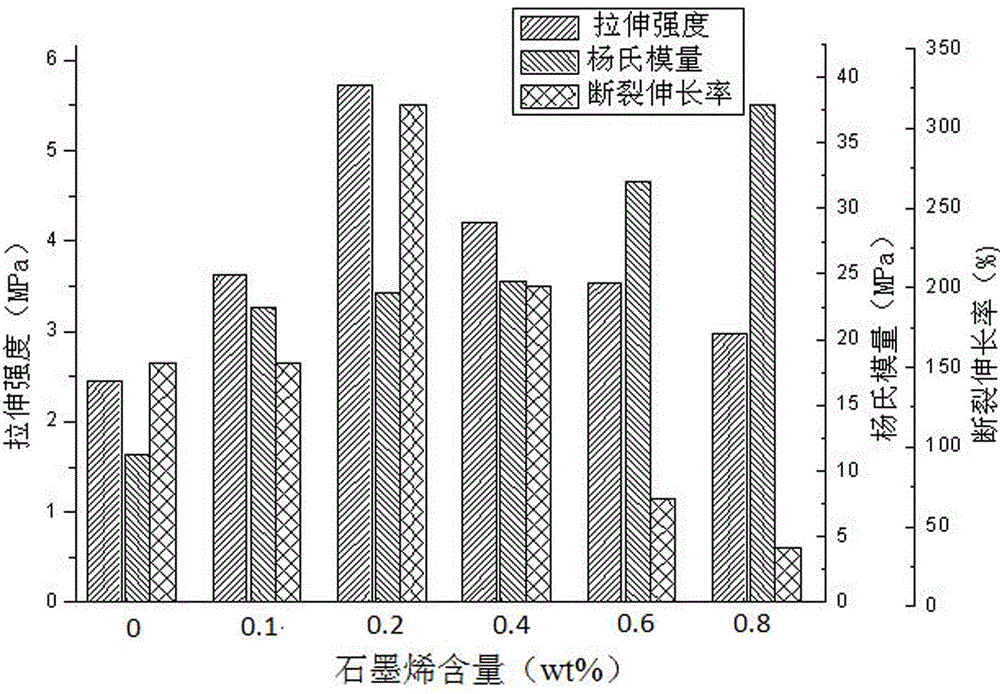

[0030] (2) The graphene-containing polyurethane powder obtained in step (1) was hot-pressed at 210°C and 15 MPa for 10 minutes, and graphene / polyurethane conductive composite materials wit...

Embodiment 2

[0032] The preparation method of the gradient graphene / polyurethane conductive composite material of the present embodiment, the steps are as follows:

[0033] (1) Choose DMF as the organic solvent, weigh 3g of TPU pellets, put them in 70ml of DMF solvent, and stir for 30min at a temperature of 40°C; according to the proportion of 0.2wt%, measure 1.333g of graphene in water dispersion , put in 20ml of DMF solvent, ultrasonic for 10min, mix the two solutions, and clean the graphene DMF beaker with 10ml of DMF solution, stir and ultrasonic for 30min again; after the mixed solution is cooled, add 500ml of methanol dropwise to obtain flocs, filter The above-mentioned flocs were put into an oven and dried for 20 hours under the condition of 80° C. to obtain the polyurethane powder containing graphene;

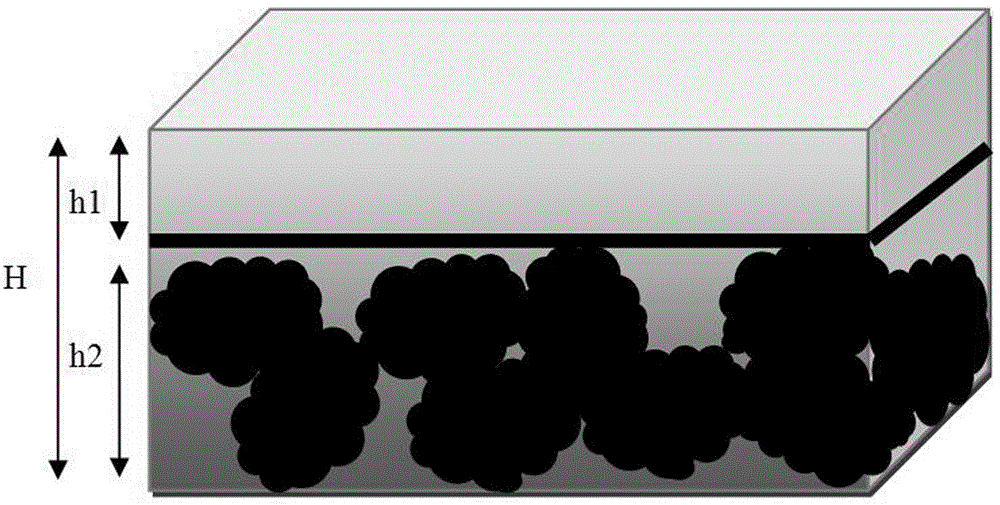

[0034] (2) Measure 4.44g of graphene in water dispersion, put it in 200ml of acetone solvent, oscillate ultrasonically for 20min, and spray (combining air compressor and vacuuming, ...

Embodiment 3

[0037] The preparation method of the gradient graphene / polyurethane conductive composite material of the present embodiment, the steps are as follows:

[0038](1) Choose DMF as the organic solvent, weigh 3g of TPU pellets, put them in 70ml of DMF solvent, and stir for 35min at a temperature of 40°C; according to the proportion of 0.4wt%, measure 2.677g of graphene in water dispersion , also put in 20ml of DMF solvent, ultrasonic 10min. Mix the two solutions, and clean the graphene DMF beaker with 10ml of DMF solution, and then sonicate again for 30min after stirring; after the mixed solution is cooled, add 500ml of methanol dropwise to obtain flocs, filter the flocs, and put them under the condition of 80°C. Dry 20h in oven, obtain the polyurethane powder that contains graphene;

[0039] (2) Measure 4.44g of graphene in water dispersion, put it in a quantitative 200ml acetone solvent, oscillate ultrasonically for 20min, and spray it on the melt-blown polyurethane non-woven fa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com