Workbench for cleaning and recycling waste scraps generated in machine element processing

A technology of mechanical parts and workbenches, which is applied in the field of parts processing, can solve problems such as splashing in the air, high processing precision of workpieces, and physical hazards, and achieve the effects of ensuring personal safety, ingenious structural design, and thorough cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

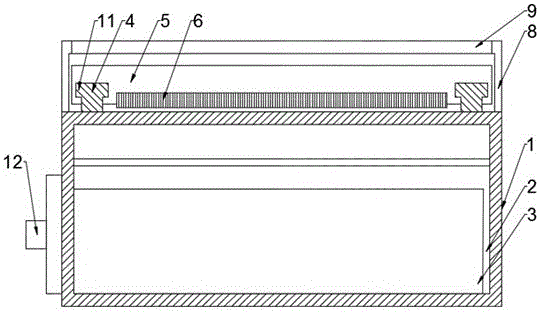

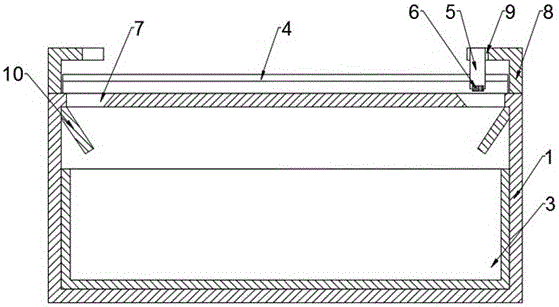

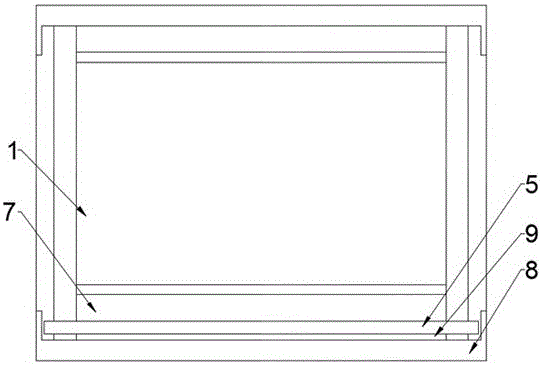

[0017] see Figure 1~3 , a workbench for cleaning and recycling mechanical parts processing waste, including a table body 1, a chip removal chamber 2 is provided in the table body 1, a drawer 3 is provided in the discharge chamber, and the left and right ends of the table surface of the table body 1 are Two guide rails 4 are arranged symmetrically. The guide rails 4 are designed with a T-shaped structure. A scraper 5 is provided directly above the table body 1. The bottom end of the scraper 5 is embedded with a brush 6. Both ends of the scraper 5 The bottom surface is symmetrically provided with a guide groove 11 matched with the guide rail 4. The guide groove 11 is also a T-shaped structure design. The front and rear ends of the table body 1 are symmetrically provided with two baffles 8. Baffle plate and horizontal baffle plate, the cross-section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com