Quick-lock anti-auxetic tire for inner hole and end face positioning workpiece

A technology for end faces and workpieces, which is applied in the field of high-precision fast locking fixtures, can solve problems such as efficiency impact, low precision, and influence on end face processing, and achieve the effects of improving processing efficiency, large operating space, and fast locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

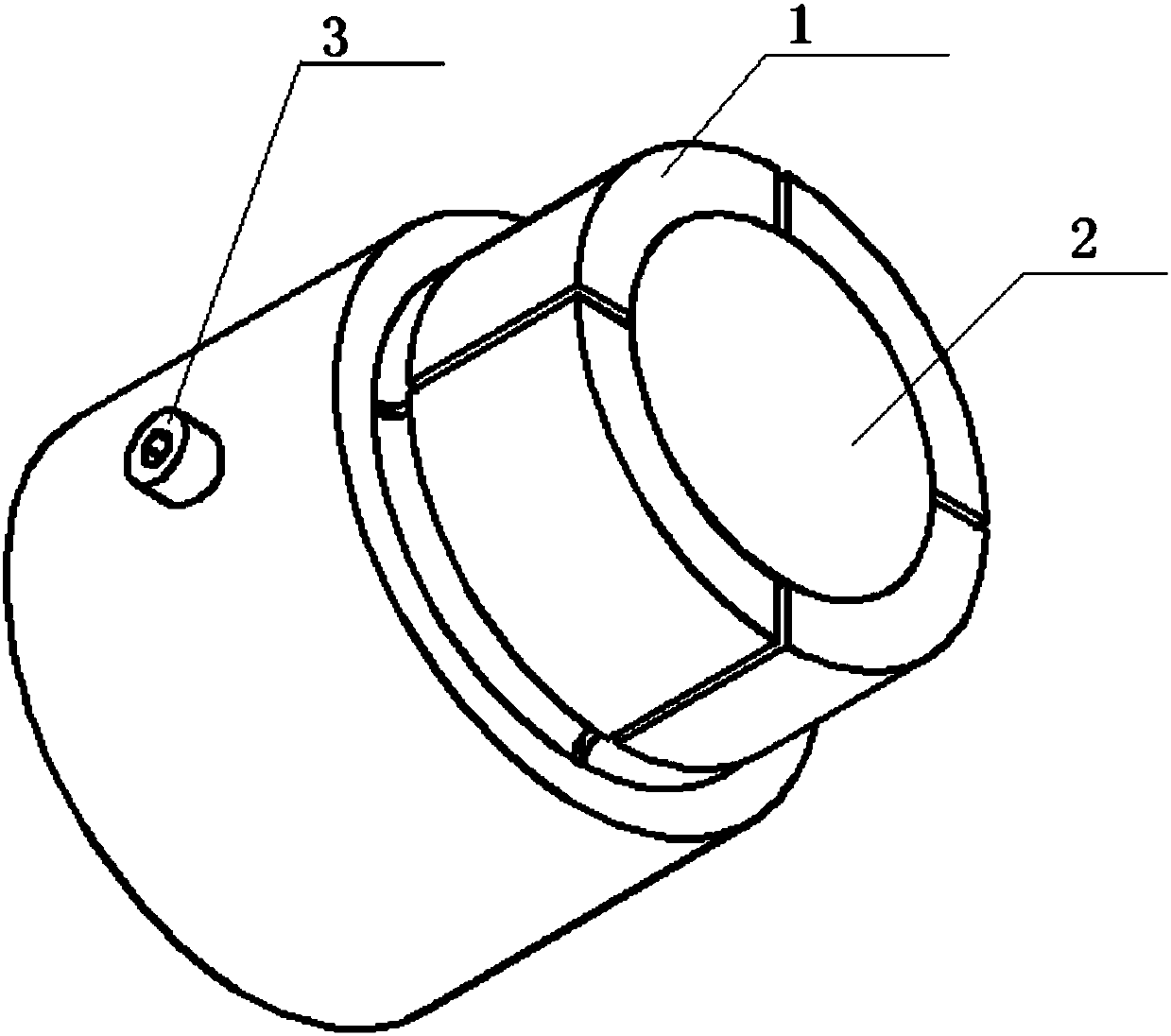

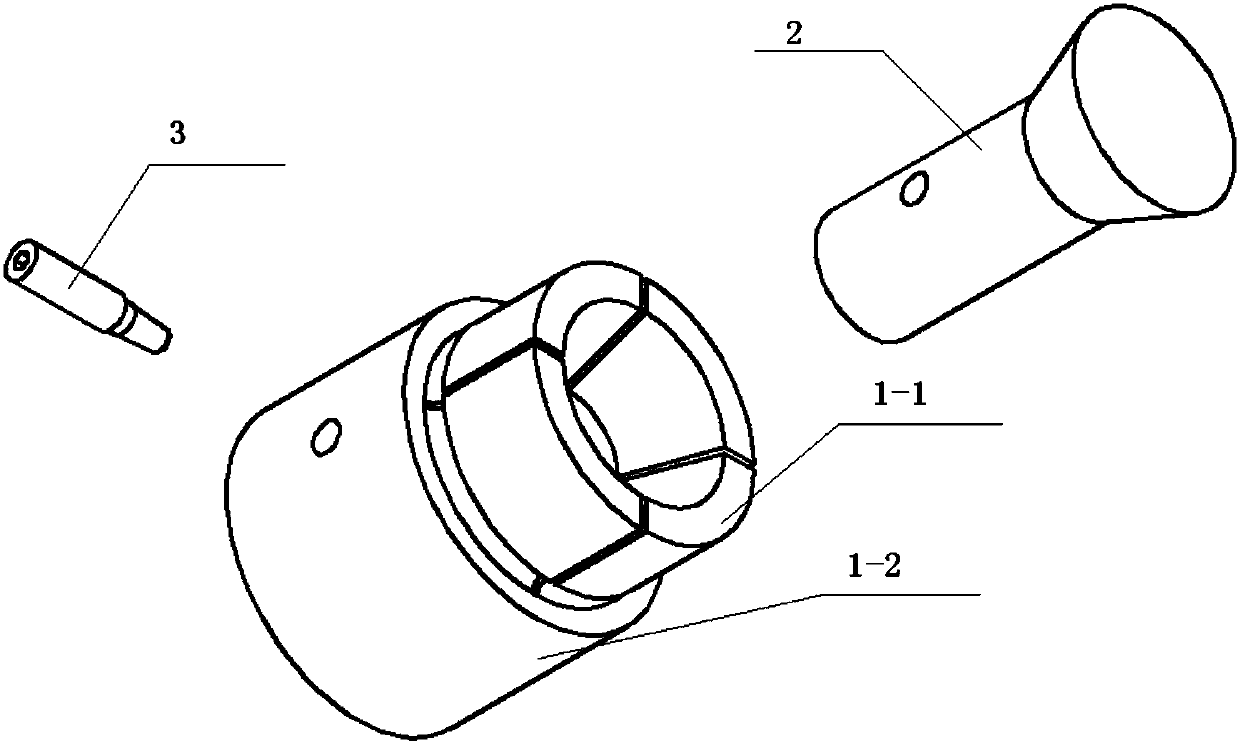

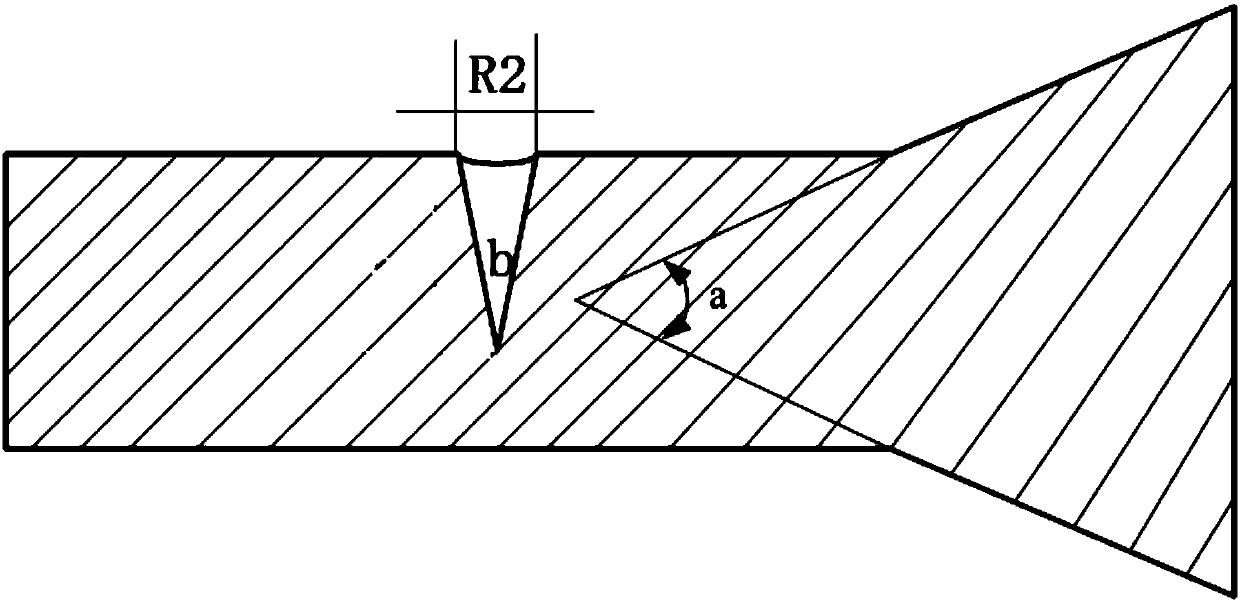

[0028] Such as figure 1 Shown is a schematic diagram of the overall structure of the quick-locking anti-stretching tire for positioning the workpiece on the inner hole and the end face. Cone top wire 3; wherein the cone mandrel 2 extends into the expansion sleeve 1 in the axial direction; the axial side wall of the expansion sleeve 1 is provided with a radial cylindrical through hole; the axial side wall of the cone mandrel 2 is provided with a radial Tapered groove; the size of the taper top screw 3 is matched with the cylindrical through hole of the expansion sleeve 1 and the tapered groove of the cone mandrel 2; after the taper mandrel 2 extends into the expansion sleeve 1 along the Radially pass through the cylindrical through hole of the expansion sleeve 1 and extend into the tapered groove of the tapered mandrel 2 to realize a fastening c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com