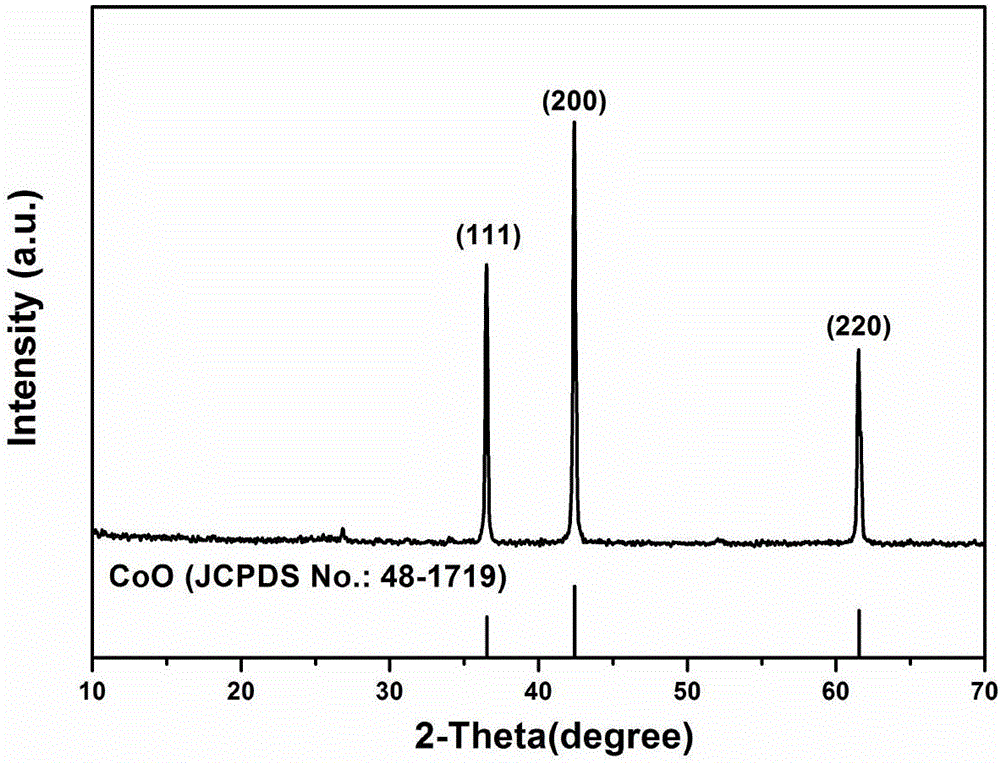

Preparation method of Super P/CoO self-assembled porous nano rodlike composite negative electrode material for lithium-ion battery

A lithium-ion battery, nanorod-like technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of difficult to control the size of loaded CoO particles, complex graphene preparation process, etc., to improve electrical conductivity and structural stability, Uniform morphology and the effect of accelerating electrochemical reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: A preparation method of Super P / CoO self-assembled porous nano-rod composite lithium-ion battery negative electrode material,

[0022] 1) Take 5ml of analytically pure isopropanolamine and add it to 65ml of deionized water, mix well to form solution A;

[0023] 2) Take 6mmol of Co(NO 3 ) 2 ·6H 2 O, 18 mmol of NH 4 Add F to solution A in sequence under stirring, and then add 0.024g of Super P after the substances in the solution are completely dissolved, and stir magnetically for 20 minutes to obtain suspension B;

[0024] 3) Ultrasonic treatment of the suspension B for 1 h;

[0025] 4) Add the ultrasonically treated suspension B into the reaction kettle, seal the reaction kettle, place it in a homogeneous reactor, heat it from room temperature to 120°C, keep it warm for 5h, and then cool it naturally to room temperature to obtain the suspension C ;

[0026] 5) The suspension C was centrifuged and washed with deionized water and absolute ethanol for 3 ti...

Embodiment 2

[0032]Example 2: A preparation method of Super P / CoO self-assembled porous nano-rod composite lithium-ion battery negative electrode material,

[0033] 1) Take 6ml of analytically pure isopropanolamine and add it to 64ml of deionized water, and mix well to form solution A;

[0034] 2) Take 6mmol of Co(NO 3 ) 2 ·6H 2 O, 20 mmol of NH 4 Add F to solution A sequentially under stirring conditions, and then add 0.06g of Super P after the substances in the solution are completely dissolved, and stir magnetically for 25 minutes to obtain suspension B;

[0035] 3) Ultrasonic treatment of the suspension B for 1.5 h;

[0036] 4) Add the ultrasonically treated suspension B into the reaction kettle, seal the reaction kettle, place it in a homogeneous reactor, heat it from room temperature to 140°C, keep it warm for 6h, and then cool it naturally to room temperature to obtain the suspension C ;

[0037] 5) The suspension C was centrifuged and washed with deionized water and absolute ...

Embodiment 3

[0039] Embodiment 3: A kind of preparation method of Super P / CoO self-assembled porous nano-rod composite lithium-ion battery negative electrode material,

[0040] 1) Take 7ml of analytically pure isopropanolamine and add it to 63ml of deionized water, mix well to form solution A;

[0041] 2) Take 6mmol of Co(NO 3 ) 2 ·6H 2 O, 22 mmol of NH 4 F is added in the solution A successively under the condition of stirring, after the substance in the solution is completely dissolved, add 0.072g of Super P, stir magnetically for 30min to obtain the suspension B;

[0042] 3) Ultrasonic treatment of the suspension B for 2 hours;

[0043] 4) Add the ultrasonically treated suspension B into the reaction kettle, seal the reaction kettle, place it in a homogeneous reactor, heat it from room temperature to 160°C, keep it warm for 7h, and then cool it naturally to room temperature to obtain the suspension C ;

[0044] 5) The suspension C was centrifuged and washed with deionized water an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com