Double-channel heat exchange system and its air temperature adjustment method

A heat exchange system and air temperature technology, applied in indirect heat exchangers, heat exchanger types, heat exchange equipment, etc., can solve the problems of insufficient utilization of heat source heat, insufficient heat utilization, and inability to utilize water drainage, etc. Simple, fully recycled, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention are described in detail below:

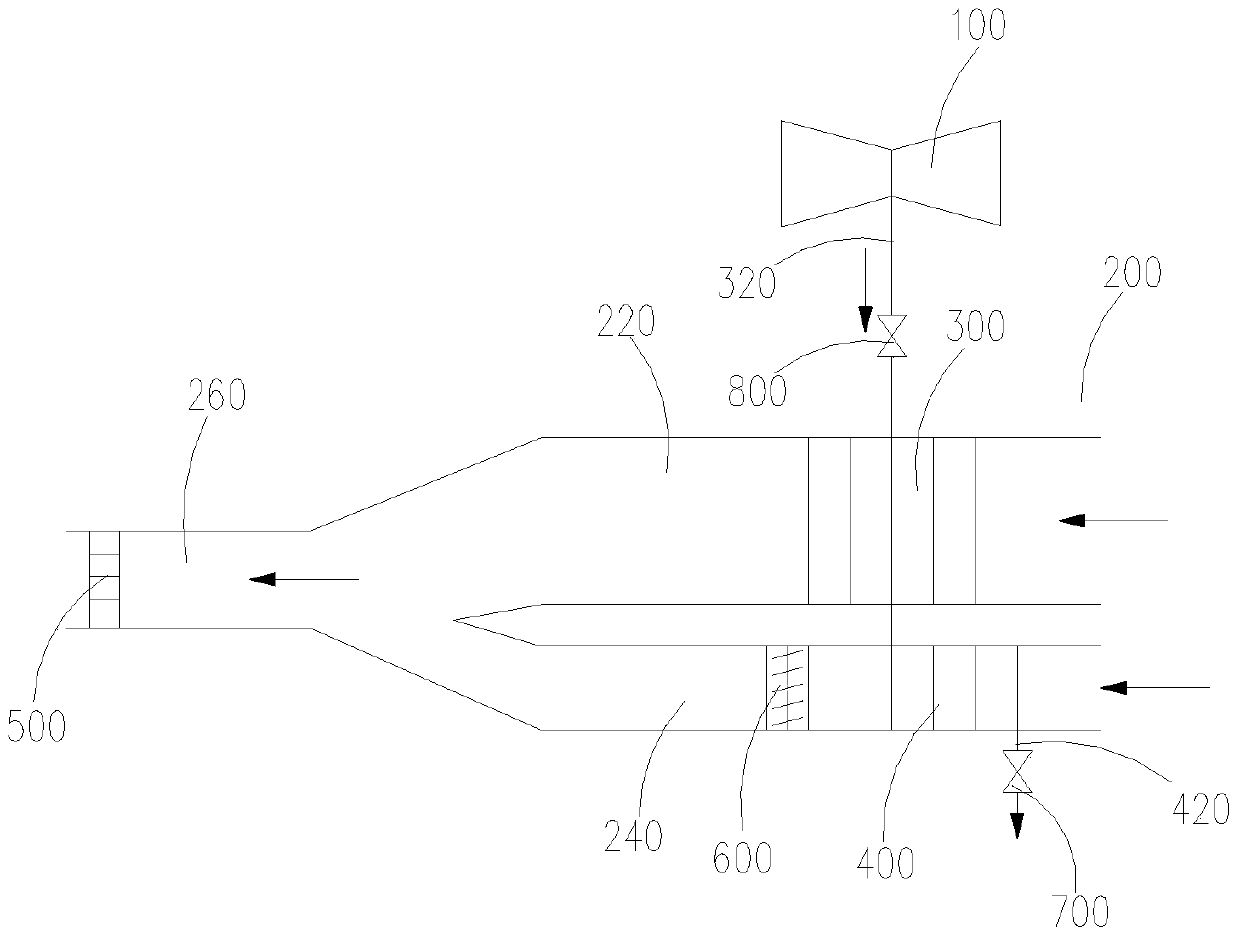

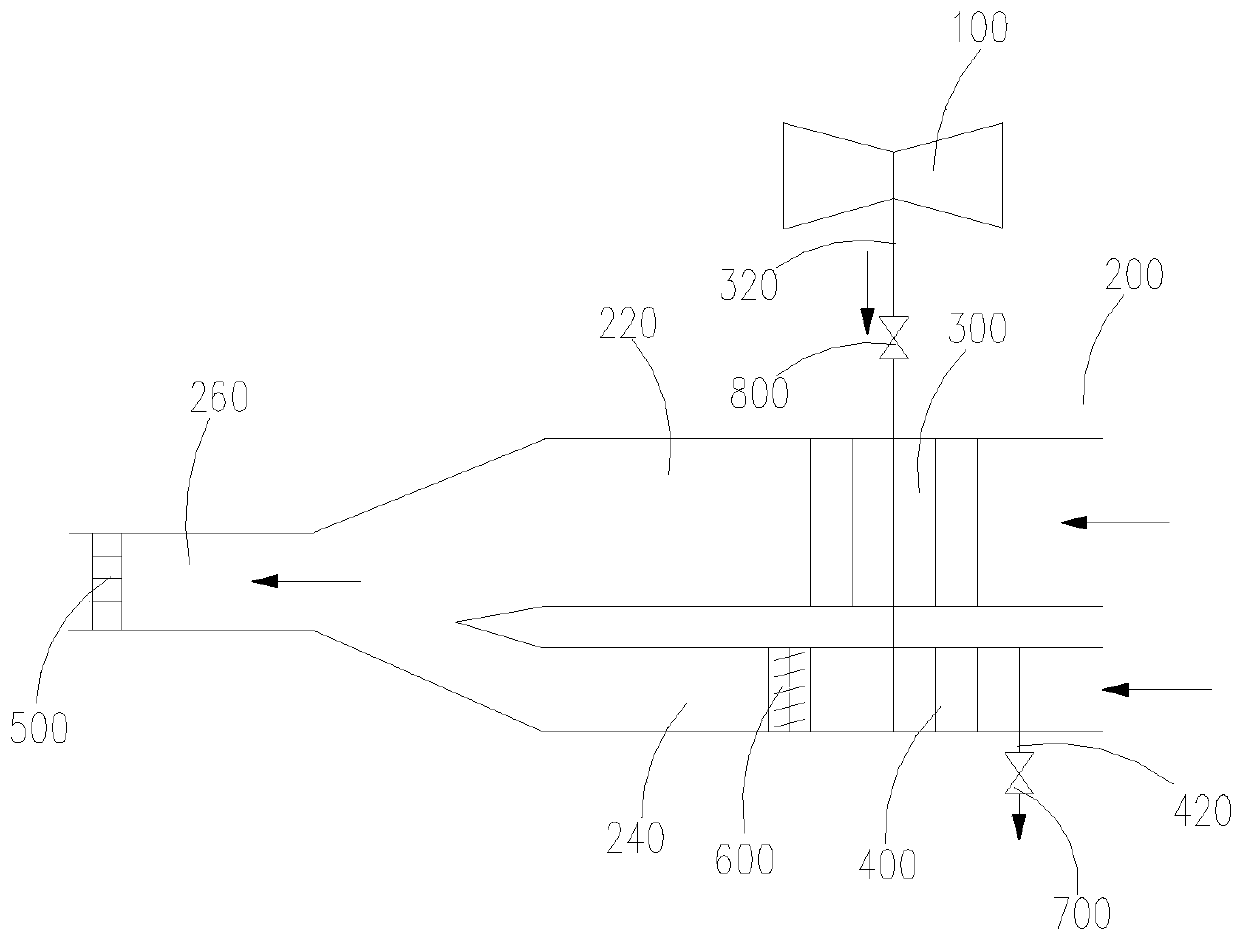

[0026] Such as figure 1 As shown, a double-channel heat exchange system includes a steam supply device 100, at least two heat exchange channels 200 arranged side by side and connected to the steam supply device 100, at least one first heat exchanger 300, and at least one first heat exchanger 300. Two heat exchangers 400, the first heat exchanger 300 and the second heat exchanger 400 are respectively arranged in the two heat exchange channels 200, and the first heat exchanger 300 includes a first drain pipe The first heat exchanger 300 communicates with the second heat exchanger 400 through the first hydrophobic pipeline 320 .

[0027] In this embodiment, preferably, the first heat exchanger 300 is a steam-air heat exchanger, the second heat exchanger 400 is a hydrophobic cooling heat exchanger, and the steam supply device 100 is a cylinder of a steam turbine unit, The cylinder communicates with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com