An online adjustable pulverized coal concentrator

A pulverized coal concentration and concentrator technology, which is applied to burners burning powder fuel, burners, and regulating fuel supply, etc., can solve the problems of short service life, wear of core components, poor adaptability, etc., and reduce the operation time. and maintenance costs, the wear allowance can be replaced, and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to understand the present invention more clearly, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments.

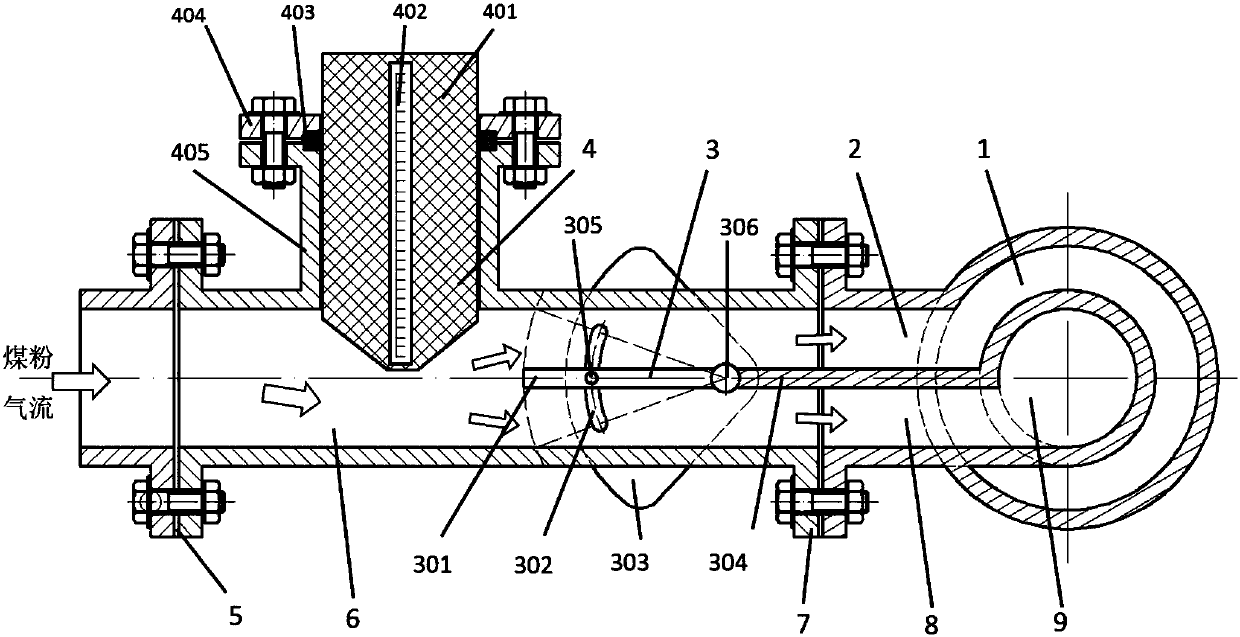

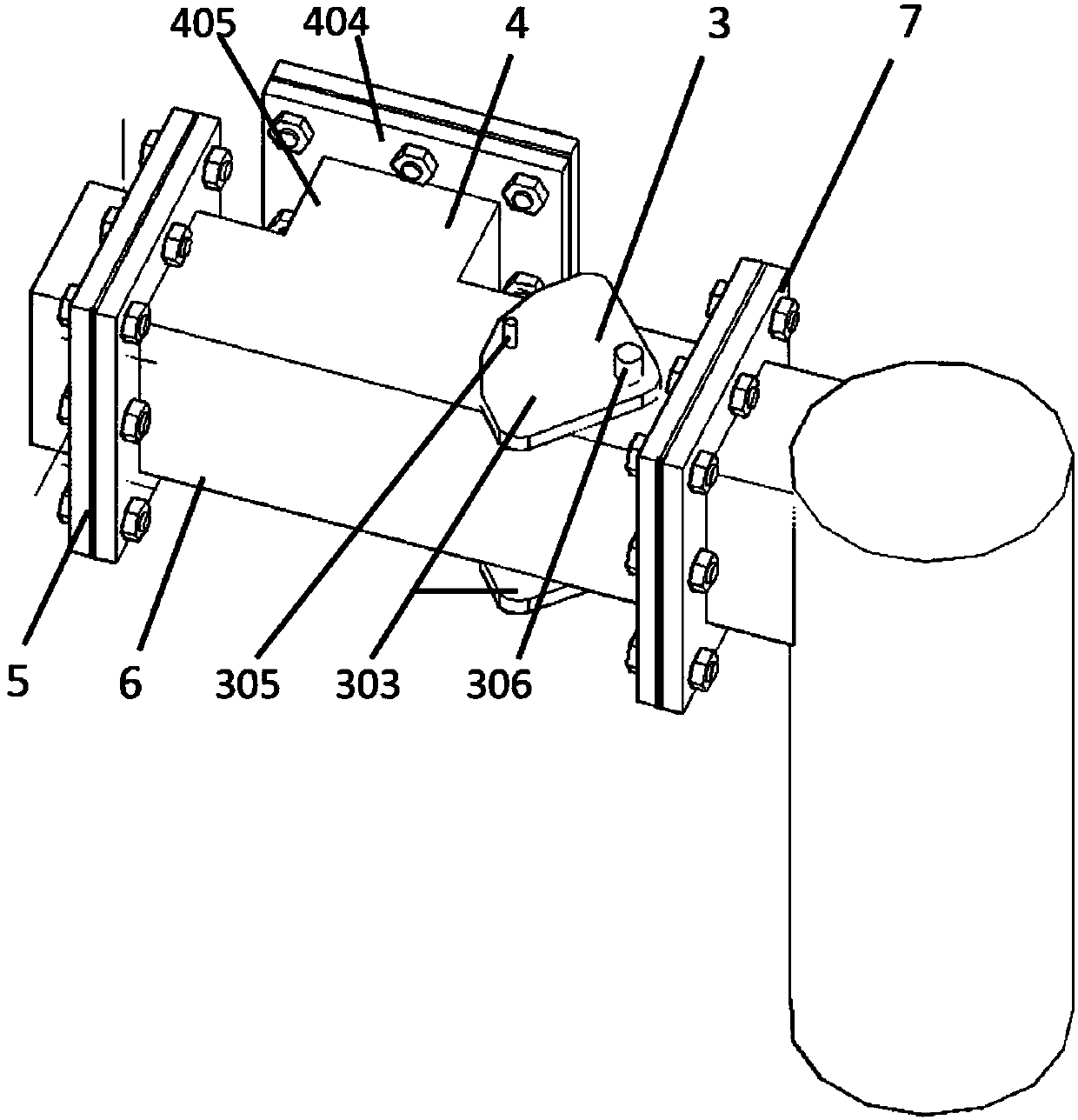

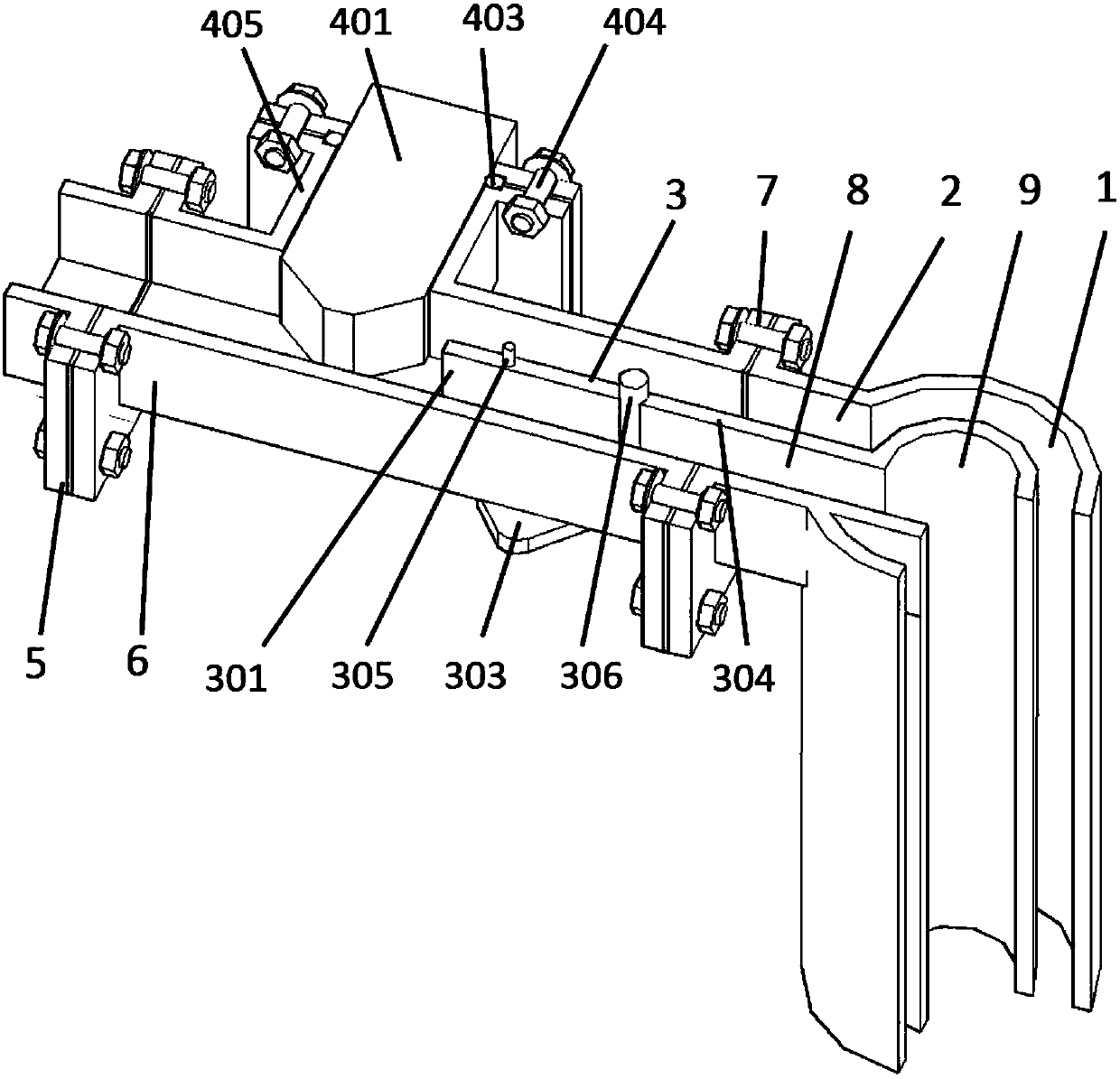

[0023] See figure 1 , 2 , 3. figure 1 It is a schematic diagram of the structure of the online adjustable pulverized coal concentrator of the present invention; figure 2 It is a three-dimensional schematic diagram of the online adjustable pulverized coal concentrator of the present invention; image 3 It is a three-dimensional cross-sectional view of the online adjustable pulverized coal concentrator of the present invention.

[0024] According to the technical scheme of the present invention, an online adjustable pulverized coal concentrator includes a pulverized coal airflow channel 6, an adjustable block mechanism 4, an adjustable pulverized coal diversion mechanism 3, a light side pulverized coal channel 2, a thick side pulverized coal channel 8 , External primary air 1, internal primary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com