Edge joint connecting structure and method of prefabricated integrated type frame column beam

A connection structure and node connection technology, which is applied in the direction of building structure and construction, can solve the problems of unfavorable development of building industrialization, insufficient connection strength, cumbersome process, etc., and achieve the effects of convenient hoisting and transportation, convenient construction and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

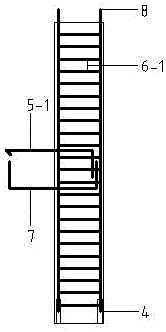

Image

Examples

Embodiment

[0039] In the construction of a 6-story residential building in a pilot project, the cross-sectional size of the prefabricated columns is 600mm×600mm, the cross-sectional size of the prefabricated beams is 400mm×600mm, the concrete layer is made of C30 concrete, and the longitudinal bars and stirrups are all made of HRB400 steel bars , the thickness of the concrete protective layer is 20mm.

[0040] 1. Factory prefabricated part:

[0041] Production of prefabricated columns: 12 vertical bars with a diameter of 25mm are evenly arranged around the column, and in order to install the grouting sleeve, the bottom of the vertical bars is 100mm higher than the bottom of the column, and the top of the vertical bars is also higher than (extruded) the column Top 100mm; Stirrups I with a diameter of 10mm and a spacing of 100mm are evenly arranged along the direction of the vertical bar; four U-shaped steel bars with a diameter of 25mm are arranged on the lower part of the column-beam joi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com