A preparation method for in-situ generation of titanium-zirconium boride reinforced high-modulus high-hardness steel

An in-situ generation, boride technology, applied in the field of steel-based composite materials, can solve problems such as complex process, and achieve the effects of simple process, good wear resistance, and good neutron control ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

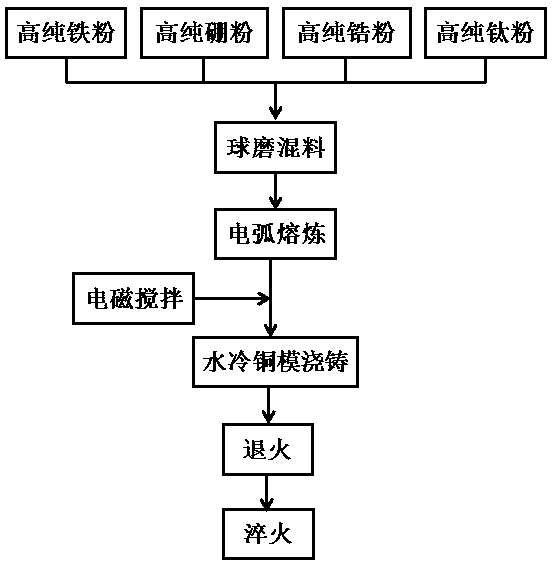

[0027] A preparation method for in-situ generation of titanium-zirconium boride reinforced high-modulus high-hardness steel, the specific steps are as follows:

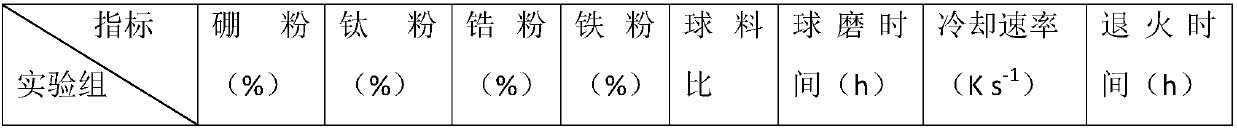

[0028] Step 1. First, weigh the boron powder, titanium powder, zirconium powder and high-purity iron powder with a purity of more than 99.99% according to the mass percentage of B3.52%, Ti 7.60%, Zr 5.80%, and put the powder into a ball mill tank Mix the materials with a planetary ball mill, the ball-to-material ratio is 10:1, and the ball milling time is 3 hours;

[0029] Step 2. Take out the mixed powder obtained in step 1, put it in the copper crucible of the vacuum arc melting furnace, and melt it under the protective atmosphere of argon gas, and at the same time, continuously process the melt by electromagnetic stirring to make the melt completely homogenized , while refining the precipitated phase and matrix structure, the sample was cast in a water-cooled copper mold with a cooling rate of 5K s -1 .

[0030] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com