Preparation method of alpha-2,3-sialyllactulose

A technology of sialylation and lactulose, which is applied to the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve problems such as the difficulty of lactulose sialic acid glycosylation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

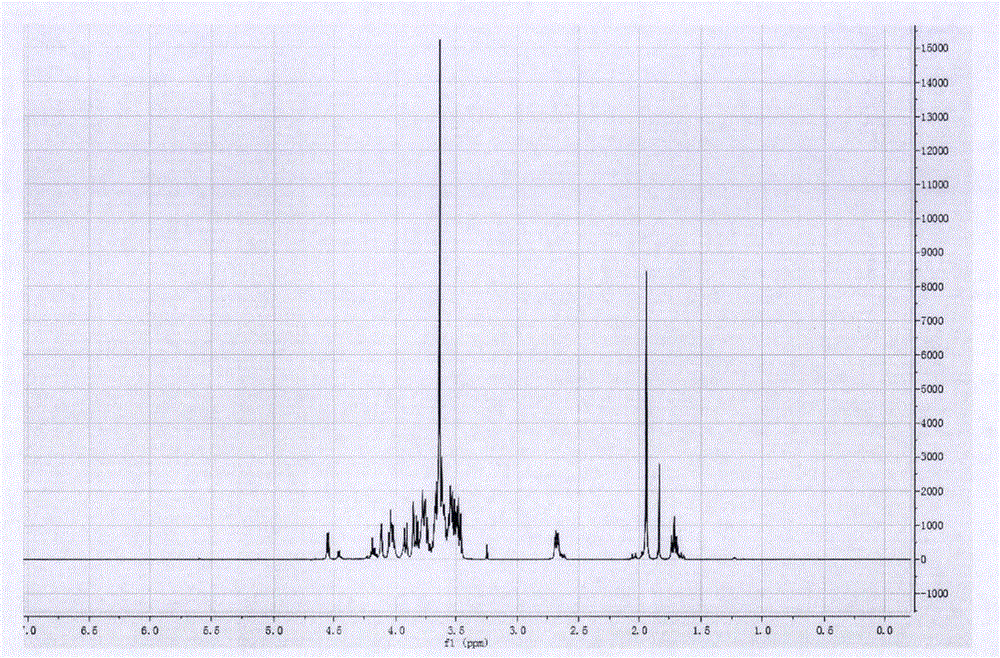

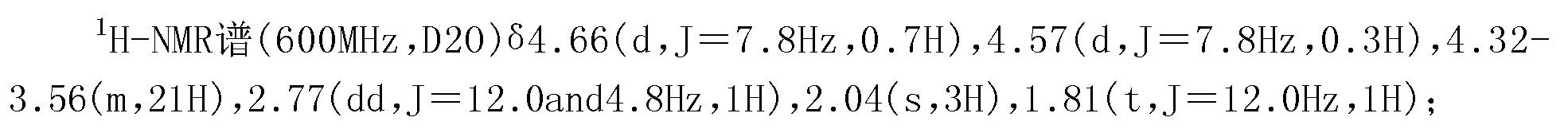

Image

Examples

Embodiment 1

[0011] Raw material formula lactulose 40mg, cytidine sodium triphosphate (CTP) 95mg, sialic acid (Neu5Ac) 53mg, dissolved in 3000mg ultrapure water, adjusted pH 8.5 with 3 mol / L NaOH, added 1 mol / L pH 8 .5 Tris-HCl to make the concentration in the reaction system 100 mmol / L; 2 mol / L MgCl 2 , Make the concentration in the reaction system 20 mmol / L; 1mg CMP-sialyltransferase (NmCSS); 2mg sialyltransferase, namely PmST 1 . The mixture was then placed in a 37°C gas bath shaker and reacted for 20 hours. The degree of reaction was detected by silica gel thin layer chromatography (TLC), and the developing solvent of TLC was n-propanol:methanol:water=5:2:1. After the lactulose reaction is complete, add an equal volume of 95% ethanol to the reaction solution, mix well, put it in a refrigerator at 4°C for 30 minutes, then centrifuge at 7000 rpm for 30 minutes, and concentrate the supernatant by rotary evaporation. The concentrate was purified by silica gel chromatography. The ratio of ...

Embodiment 2

[0013] Lactulose 40mg, cytidine triphosphate (CTP) 110mg, sialic acid (Neu5Ac) 60mg, dissolved in 3000mg ultrapure water, adjusted pH 8.5 with 3 mol / L NaOH, and added 1 mol / L pH 8.5 Tris-HCl to make the concentration in the reaction system 100mM; 2mol / L MgCl 2 , The concentration in the reaction system is 20 mmol / L; 1.5mg CMP-sialyltransferase (NmCSS); 2.5mg sialyltransferase (PmST 1 ). The mixture was then placed in a 37°C gas bath shaker and reacted for 24 hours. The degree of reaction was detected by silica gel thin layer chromatography (TLC), and the developing solvent of TLC was n-propanol:methanol:water=5:2:1. After the lactulose reaction is complete, add an equal volume of 95% ethanol to the reaction solution, mix well, put it in a refrigerator at 4°C for 30 minutes, then centrifuge at 7000 rpm for 30 minutes, and concentrate the supernatant by rotary evaporation. The concentrate was purified by silica gel chromatography. The ratio of the purification solvent is ethyl ...

Embodiment 3

[0015] 40mg lactulose, 90mg cytidine triphosphate (CTP) 90mg, sialic acid (Neu5Ac) 50mg, dissolved in 3000mg ultrapure water, adjusted pH8.5 with 3mol / L NaOH, added 1mol / L pH8.5 Tris-HCl to make the concentration in the reaction system 100 mmol / L; 2 mol / L MgCl 2 , Make the concentration in the reaction system 20 millimoles / liter; 1.2mg of CMP-sialyltransferase, namely NmCSS; 2.3mg of sialyltransferase, namely PmST 1 . The mixture was then placed in a 37°C gas bath shaker and reacted for 26 hours. The degree of reaction was detected by silica gel thin layer chromatography (TLC), and the developing solvent of TLC was n-propanol:methanol:water=5:2:1. After the lactulose reaction is complete, add an equal volume of 95% ethanol to the reaction solution, mix well, put it in a refrigerator at 4°C for 30 minutes, then centrifuge at 7000 rpm for 30 minutes, and concentrate the supernatant by rotary evaporation. The concentrate was purified by silica gel chromatography. The ratio of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com