Preparation method for glyphosate dimethylamine salt active compound

A technology of glyphosate dimethylamine salt and glyphosate, which is applied in the field of preparation of glyphosate dimethylamine salt technical material, can solve the problem of severe exothermic reaction, which is very difficult to control and requires very strict sealing conditions for equipment and other problems, to overcome the effect of greatly reducing the reaction area, good quality of the original drug, and increasing the reaction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

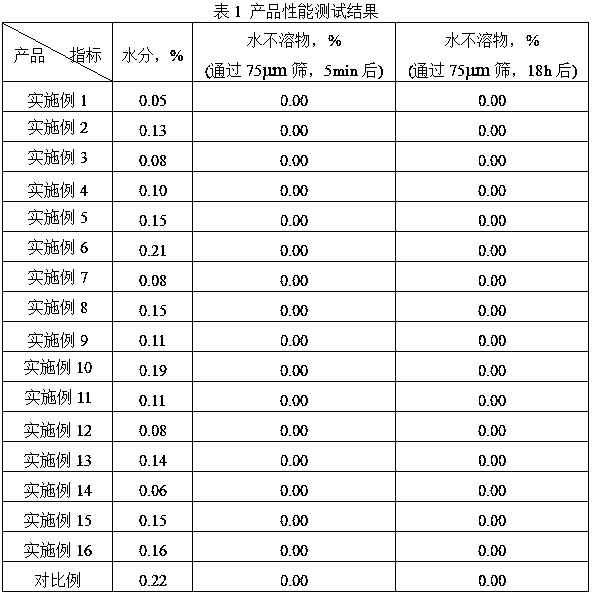

Examples

Example Embodiment

[0033] Example 1

[0034] Put 1000 g of glyphosate technical material (95% content) into the kneader, add 50 g of water at 5°C and mix evenly, and add 253 g of pure liquid dimethylamine (99.9% content) dropwise under sealed conditions, The dropwise addition time was 5 h. Due to the vaporization of dimethylamine and the increase in temperature, the reaction pressure gradually increased, up to 0.1 MPa. After the dropwise addition, the temperature was raised to 50 °C and the reaction was continued for 30 min. The excess dimethylamine was put into the absorption tower, and then discharged, and the obtained wet material was dried for 0.5 hours at a pressure of -0.08 MPa and 30°C to obtain a content of 96.1% (the content was determined by HPLC method, the same below). Glyphosate dimethylamine salt 1242.9 g, the yield (yield is calculated as glyphosate, the same below) is 99.2%.

Example Embodiment

[0035] Example 2

[0036] Put 1000 g of glyphosate technical material (content 95%) into the kneader, add 50 g of water at 70°C and mix evenly, add 253 g of pure liquid dimethylamine (content 99.9%) dropwise under sealed conditions, The dropwise addition time is 2 h. Due to the gasification of dimethylamine and the increase of temperature, the reaction pressure gradually increases, up to 0.1 MPa. The absorption tower was then discharged, and dried at a pressure of -0.08 MPa and 70°C for 0.5 hours to obtain 1245.7 g of glyphosate dimethylamine salt with a content of 95.9% and a yield of 99.4%.

Example Embodiment

[0037] Example 3

[0038] Put 1000 g of glyphosate technical material (content 95%) into the kneader, add 100 g of water at 80°C and mix evenly, add 253 g of pure liquid dimethylamine (content 99.9%) dropwise under sealed conditions, The dropwise addition time is 1 h. Due to the gasification of dimethylamine and the increase of temperature, the reaction pressure gradually increases, up to 0.1 MPa. The absorption tower was then discharged, and dried at a pressure of -0.08 MPa and 80°C for 1 hour to obtain 1244.7 g of glyphosate dimethylamine salt with a content of 95.8% and a yield of 99.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com