Mechanical self-adapting deformation blade

An adaptive and mechanical technology, applied in the field of wind turbine blades, can solve the problems of easy swelling of blades, extra energy consumed by blades, energy consumption, etc., achieve low sealing requirements, improve wind energy utilization, and simple manufacturing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

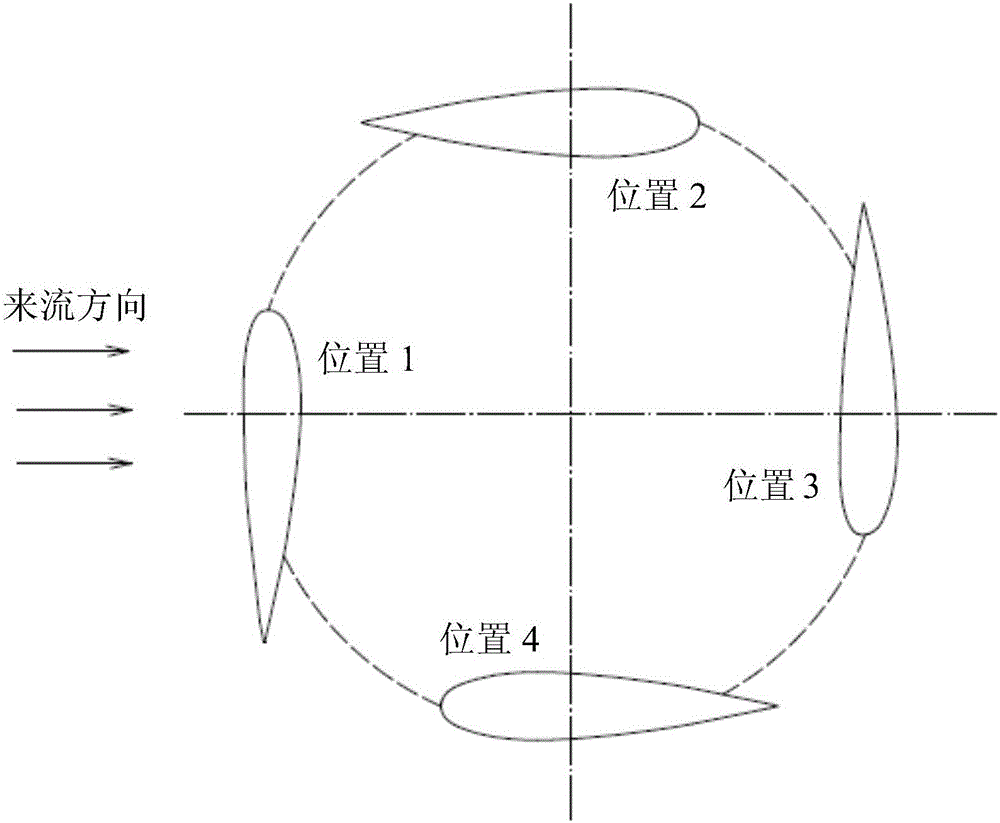

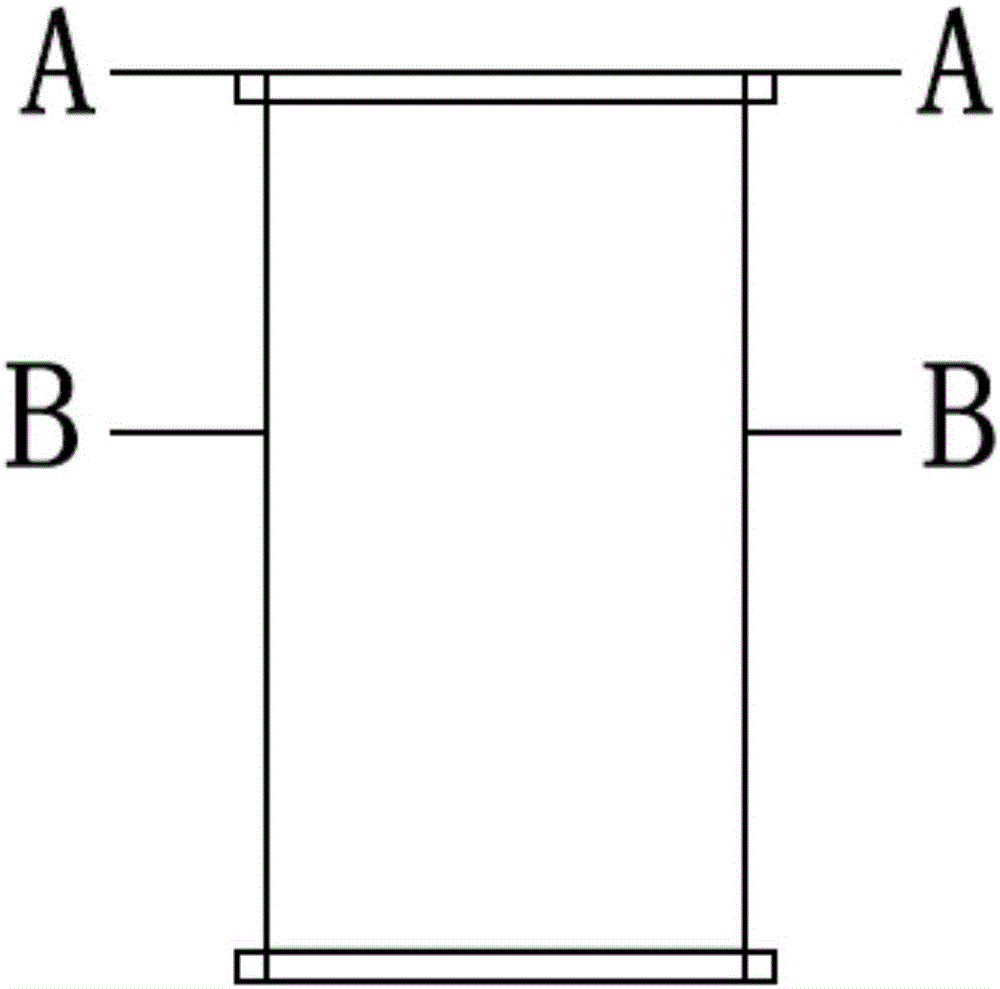

[0024] like Figure 1 to Figure 8 As shown, the main body of the mechanical self-adaptive deformable blade of the present invention includes a flexible airfoil shell 2, a crescent-shaped cylinder 3, a beam 4, a flexible skin 1, and the like.

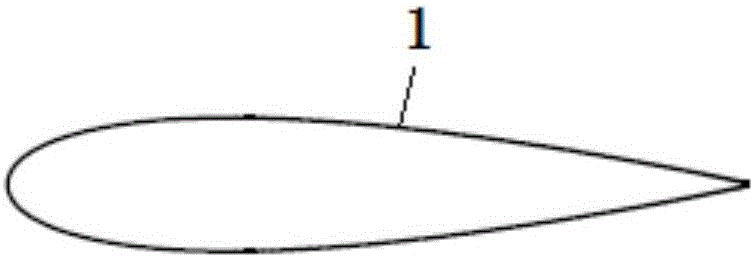

[0025] like Figure 2 to Figure 4 As shown, the flexible airfoil shell 2 is sealed by the upper and lower ends of the blades with an elastic flexible skin 1, and the flexible skin 1 deforms with the deformation of the blades. The flexible airfoil shell 2 can be made into a NACA airfoil shape with a certain thickness. NACA airfoil sides are integral and have no seams. The leading edge and the trailing edge of the flexible airfoil shell 2 are connected by a crossbeam 4, and the crescent-shaped column is installed on the crossbeam through a hinge, and the crescent-shaped column can be flexibly moved. There is a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com