Vertical type rotating impeller and vertical type wind driven generator

A vertical, flip-blade technology, applied to wind turbines, wind turbines at right angles to the wind direction, wind motor combinations, etc., can solve the problems of only working when facing the wind, low utilization rate of wind energy, small wind receiving area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

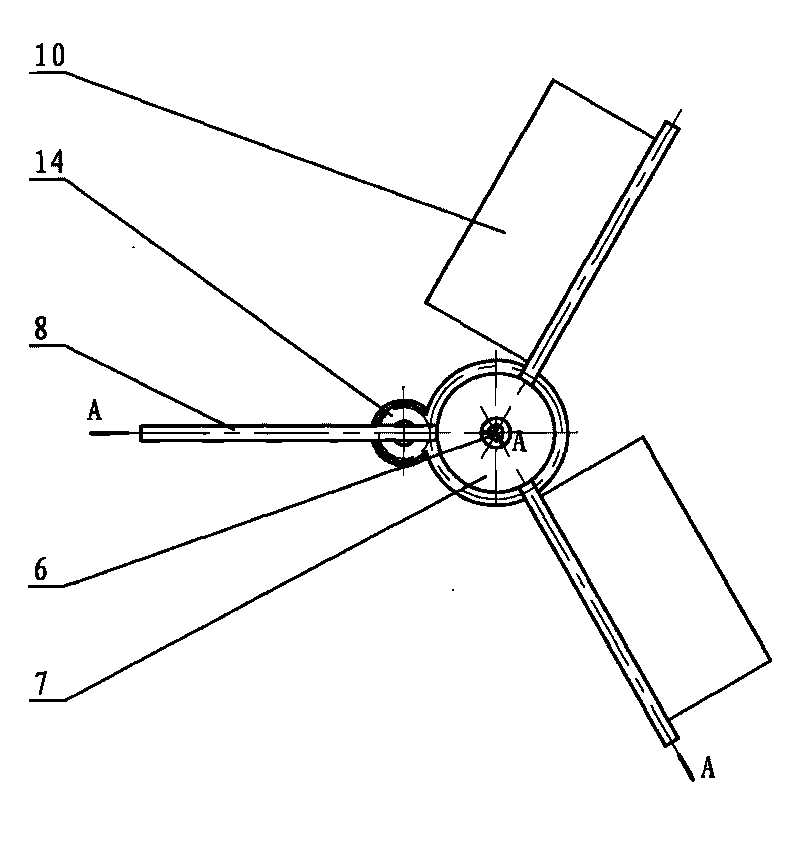

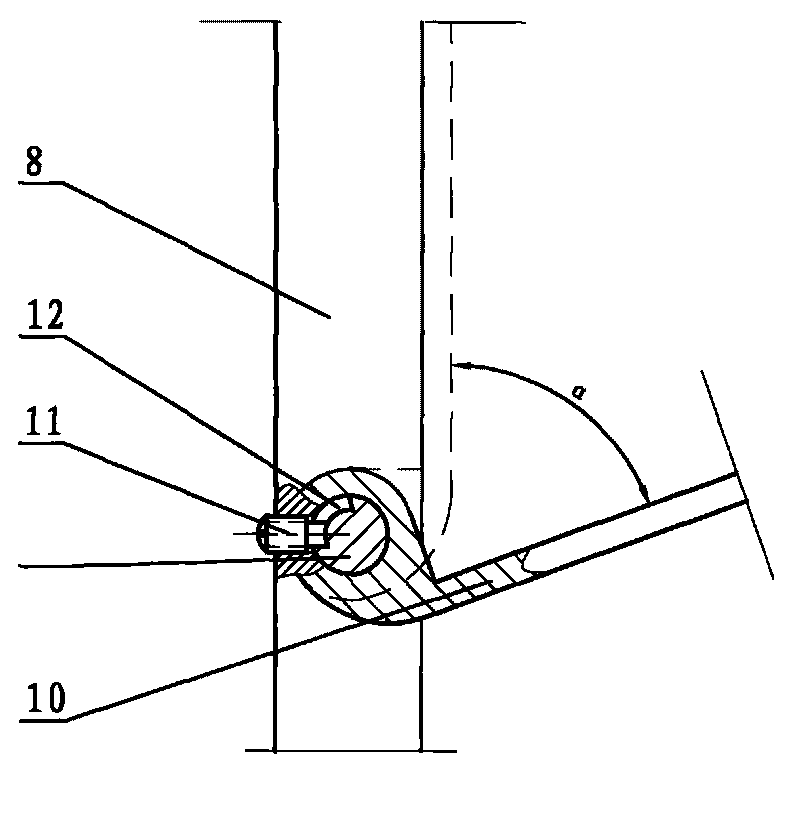

[0023] Such as Figure 1 to Figure 3 As shown, the first embodiment of the vertical flip impeller of the present invention includes a vertical support device, the vertical support device includes a main shaft 1, the lower end of the main shaft 1 is vertically fixed on the base 2, and the upper and lower ends of the main shaft 1 are equipped with rolling bearings 3, The sleeve rotor 4 is installed on the main shaft 1 through the rolling bearing 3, the sleeve rotor 4 can rotate around the main shaft 1, the thrust bearing 5 is installed between the lower end surface of the sleeve rotor 4 and the base 2, and the upper end of the main shaft 1 is passed through the fastening bolt 6 Equipped with thrust washer 7. Three sets of rotor frames 8 are fixed on the outer side of the sleeve rotor 4. Five blade shafts 9 perpendicular to the main shaft 1 are mounted on the rotor frame 8. Turning blades 10 are mounted on the blade shafts 9. The blade shafts 9 and the turning blades 10 can be po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com