A kind of cement-based engineering material with early strength, low shrinkage and high toughness and preparation method thereof

An engineering material, low-shrinkage technology, applied in climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of debonding between repair layer and base layer, high content of PVA fiber, limiting large-scale application, etc. Achieve the effect of improving debonding and cracking, good working performance and excellent volume stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

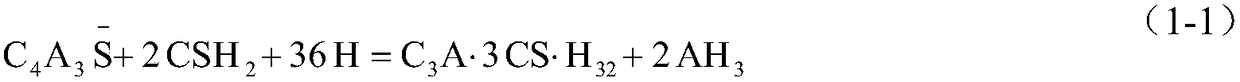

Method used

Image

Examples

Embodiment 1

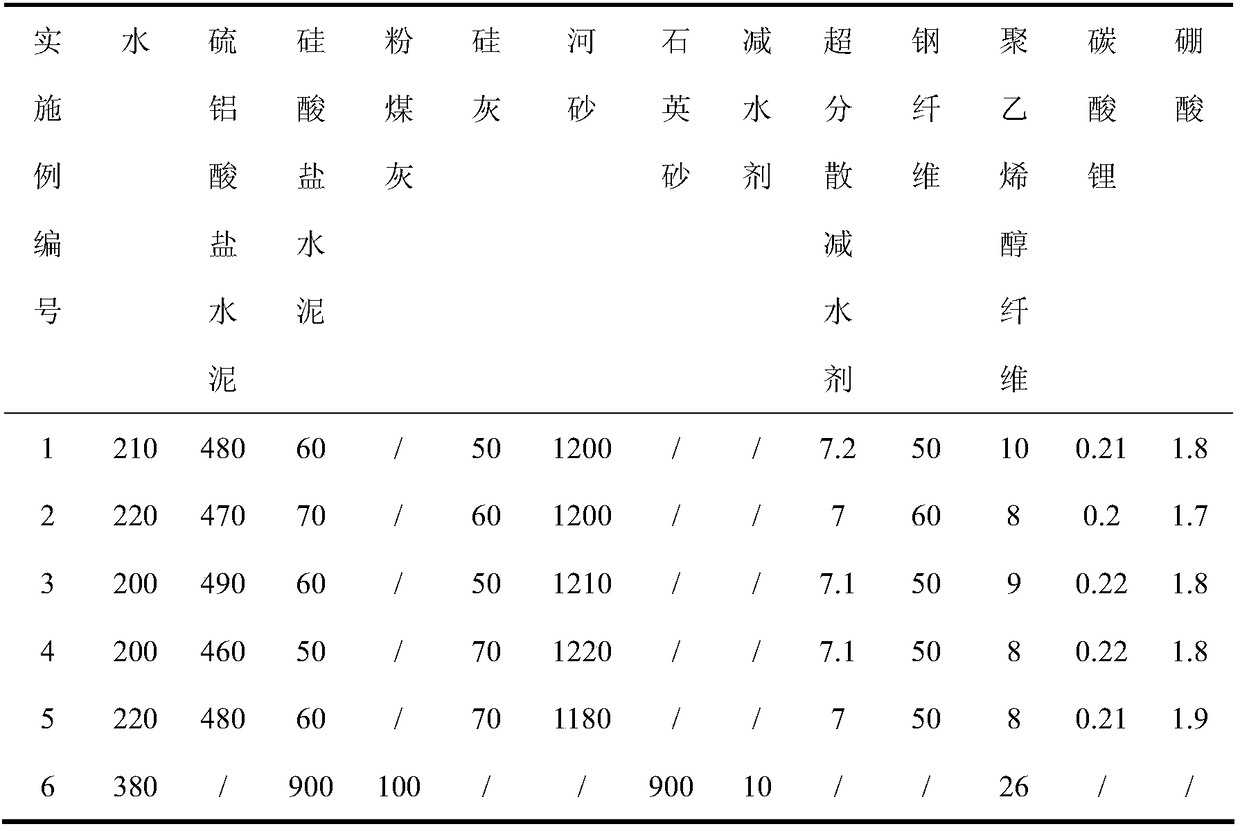

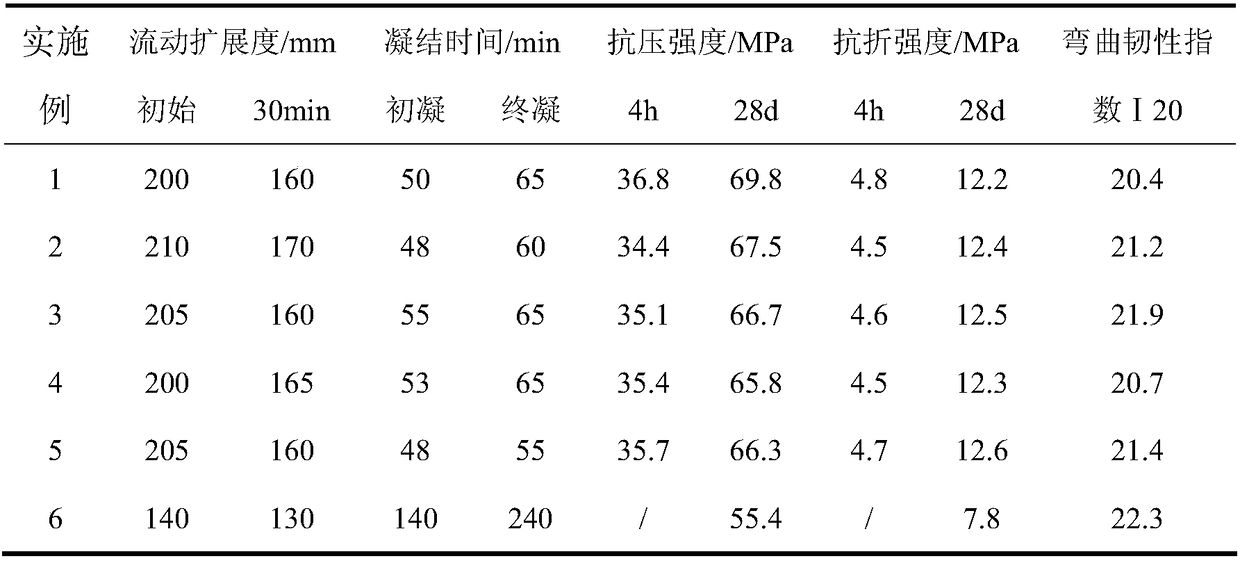

[0039] A kind of early-strength low-shrinkage high-toughness cement-based engineering material, the weight ratio of each raw material (kg / m 3 ) is: water 210, sulfoaluminate cement 480, ordinary Portland cement 60, silica fume 60, steel fiber 50, polyvinyl alcohol fiber 10, water reducing agent 7.2, early strength agent 0.21, retarder 1.8, river Sand 1200.

[0040] The above-mentioned preparation method of an early-strength low-shrinkage high-toughness cement-based engineering material comprises the following steps:

[0041] 1) Take raw materials according to the above raw material ratio;

[0042] 2) Take part of the water and heat it into warm water (the temperature of the warm water is 45-60° C.), respectively dissolving the early strength agent (lithium carbonate) and the retarder (boric acid) in warm water to obtain a lithium carbonate solution and a boric acid solution;

[0043] 3) Mix sulphoaluminate cement, ordinary Portland cement, silica fume and river sand dry-mixe...

Embodiment 2

[0049] A kind of early-strength low-shrinkage high-toughness cement-based engineering material, the weight ratio of each raw material (kg / m 3 ) is: water 220, sulfoaluminate cement 470, ordinary Portland cement 70, silica fume 60, steel fiber 60, polyvinyl alcohol fiber 8, water reducing agent 7, early strength agent 0.2, retarder 1.7, river Sand 1200.

[0050] The above-mentioned preparation method of an early-strength low-shrinkage high-toughness cement-based engineering material comprises the following steps:

[0051] 1) Take raw materials according to the above raw material ratio;

[0052] 2) Take part of the water and heat it into warm water (the temperature of the warm water is 45-60° C.), respectively dissolving the early strength agent (lithium carbonate) and the retarder (boric acid) in warm water to obtain a lithium carbonate solution and a boric acid solution;

[0053] 3) Mix sulphoaluminate cement, ordinary Portland cement, silica fume and river sand dry-mixed fo...

Embodiment 3

[0059] A kind of early-strength low-shrinkage high-toughness cement-based engineering material, the weight ratio of each raw material (kg / m 3 ) is: water 200, sulfoaluminate cement 490, ordinary Portland cement 60, silica fume 50, steel fiber 50, polyvinyl alcohol fiber 9, water reducing agent 7.1, early strength agent 0.22, retarder 1.8, river Sand 1210.

[0060] The above-mentioned preparation method of an early-strength low-shrinkage high-toughness cement-based engineering material comprises the following steps:

[0061] 1) Take raw materials according to the above raw material ratio;

[0062] 2) Take part of the water and heat it into warm water (the temperature of the warm water is 45-60° C.), respectively dissolving the early strength agent (lithium carbonate) and the retarder (boric acid) in warm water to obtain a lithium carbonate solution and a boric acid solution;

[0063] 3) Mix sulphoaluminate cement, ordinary Portland cement, silica fume and river sand dry-mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com