A high modulus modified recycled asphalt mixture and its preparation method and application

A technology for recycled mixtures and asphalt mixtures, which is applied in the field of asphalt mixtures, can solve the problems that the recycled mixtures cannot rationally use asphalt modification methods, cannot effectively digest the accumulation of waste materials, and do not pay attention to organic combination, etc., to achieve Compensating for lack of fatigue performance, eliminating rutting, and prolonging durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

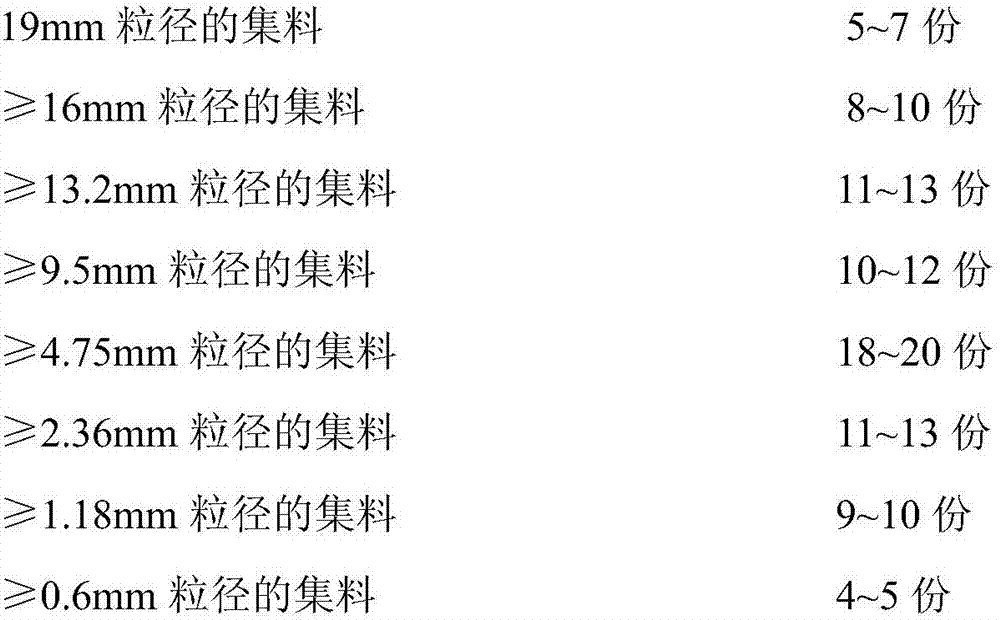

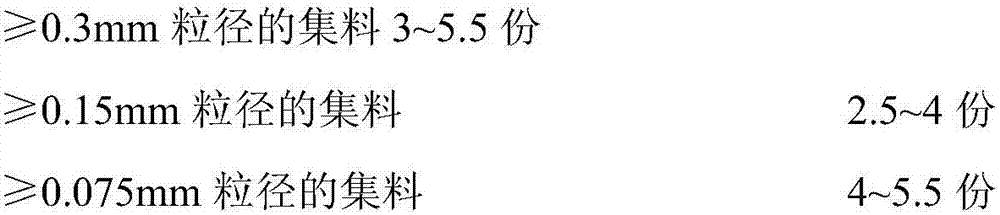

[0024] The preparation method of high modulus modified recycled asphalt mixture of the present invention comprises the following steps:

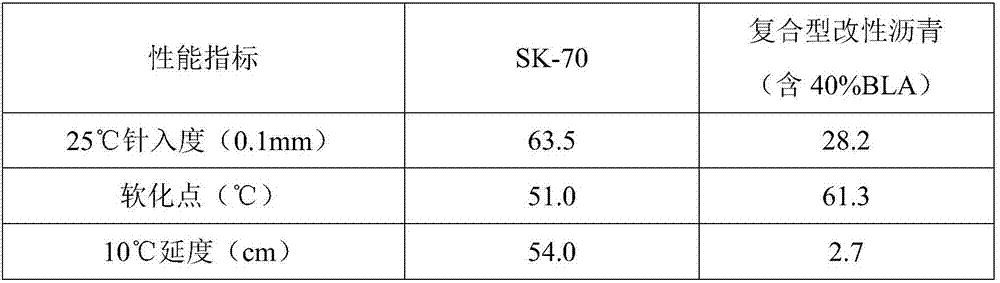

[0025] (1) Preparation of composite modified asphalt: firstly heat No. 70 road asphalt to 135°C with ordinary road asphalt SK-70 and buton rock asphalt BLA, then add rock asphalt and keep stirring for 10 minutes, so that rock asphalt can be modified in the compound type Evenly distributed in the asphalt, then put the composite modified asphalt into an oven at 160°C and incubate for 1 hour, take it out and cut it at a high speed at 170°C for 15 minutes, and test the softening point. When it reaches 60°C, it represents the composite modified asphalt If the requirements are not met, continue to add rock asphalt to make it meet the requirements. In the obtained composite modified asphalt, ordinary road asphalt SK-70 accounts for 60wt%, but pontic asphalt BLA accounts for 40%, and its performance indicators are shown in Table 1.

[0026] Table 1...

Embodiment 2

[0037] The basic steps are the same as in Example 1, except that the recycled asphalt pavement material accounts for 50 wt% of the recycled mixture.

Embodiment 3

[0039] The basic steps are the same as in Example 1, except that the recycled asphalt pavement material accounts for 60 wt% of the recycled mixture.

[0040] The high modulus modified recycled asphalt mixture prepared in Examples 1 to 3 was tested for performance, and the obtained results are shown in Table 5 to Table 9.

[0041] Table 5 Dynamic modulus

[0042] performance

none

Example 1

Example 2

Example 3

Dynamic modulus (MPa)

21024

22181

22783

24605

[0043] Table 6 Dynamic stability

[0044] performance

none

Example 1

Example 2

Example 3

Dynamic stability (times / mm)

4627

4809

5337

6980

[0045] Table 7 Low temperature performance

[0046] performance

Bending tensile strength (MPa)

Maximum Bending and Tensile Strain (με)

Bending modulus of stiffness (MPa)

none

8.51

2587

3289

Example 1

9.5

1926

4932

Example 2

11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com