Carbon nanofiber filled with metal oxide nanoparticles and preparation method thereof

A carbon nanofiber and nanoparticle technology, which is used in the processing and application of carbon nanomaterials, can solve the difference in morphology, size processing technology and cost, adverse effects of mass transfer or surface reactivity, and space limitations around filling metal oxides. and other problems, to achieve the effect of low comprehensive cost, good application prospects, and favorable mass transfer and play.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) At room temperature, put 1g of carbon nanofiber (brand PR-19-XT-PS, American PPI company) and 30ml of ferric nitrate aqueous solution (theoretical decomposition of iron tetroxide is 1g) into a planetary high-energy ball mill for adaptation In the ball mill tank, carry out 30min ball mill process under 400rpm rotating speed, filter, dry to remove moisture, pulverize and grind to obtain ferric nitrate filled carbon nanofiber;

[0044] (2) Calcining the ferric nitrate-filled carbon nanofibers obtained in step (1) at 500° C. for 30 min in a nitrogen atmosphere to obtain the target product: carbon nanofibers filled with ferric oxide nanoparticles.

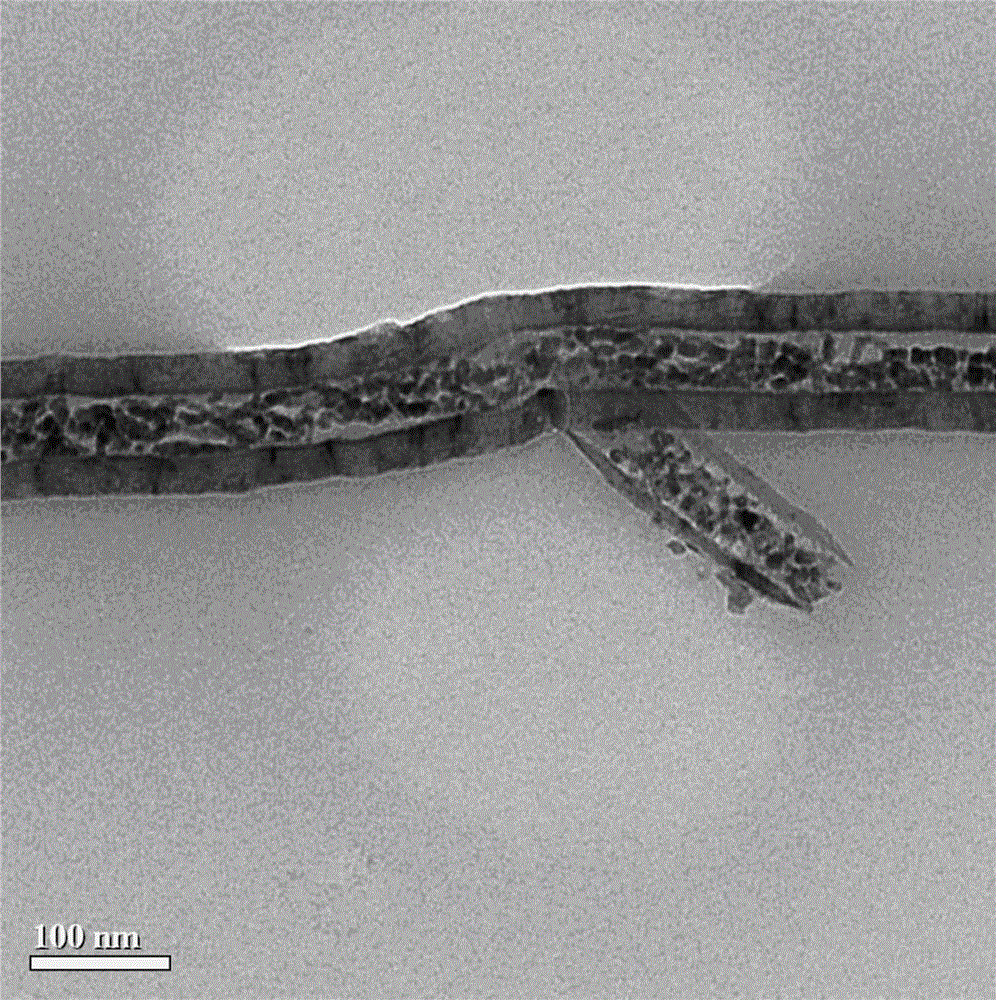

[0045] figure 1 The transmission microscope photos show that the carbon nanofiber tube has fracture marks, the port is open, and the tube is continuously filled with ferric oxide nanoparticles, the particle size is about 10nm, and it has a high filling rate. space.

Embodiment 2

[0047] (1) Put 1g of carbon nanofiber (brand PR-19-XT-PS, American PPI company) and 30ml of ferric nitrate aqueous solution (theoretical decomposition of ferric oxide is 0.5g) into a planetary high-energy ball mill at room temperature In the ball mill tank that is equipped, carry out 2h ball mill process under 200rpm rotating speed, filter, dry to remove moisture, pulverize and grind to obtain ferric nitrate filled carbon nanofiber;

[0048] (2) Calcining the ferric nitrate-filled carbon nanofibers obtained in step (1) at 250° C. for 1 h in a nitrogen atmosphere, and then calcining at 350° C. for 1 h in an air atmosphere to obtain the target product: ferric oxide nanoparticles filled carbon Nanofibers.

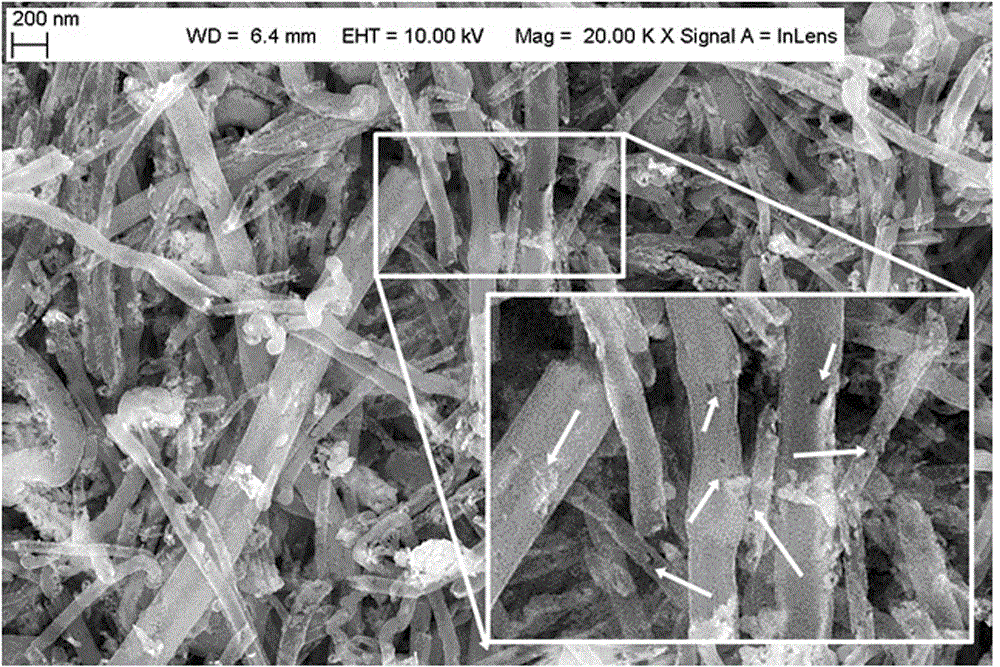

[0049] figure 2 The transmission microscope photo of the carbon nanofiber tube shows that the surface of the carbon nanofiber tube is etched with a porous structure (the arrow position in the enlarged figure in the lower right corner), and the tube is filled with ferric oxid...

Embodiment 3

[0051] (1) Put 1g of carbon nanofibers (brand PR-19-XT-PS, American PPI company) and 30ml of nickel nitrate aqueous solution (theoretical decomposition of nickel oxide is 1g) at room temperature into a ball mill tank adapted to the high-energy vibrating machine , carry out 1h of ball milling process, filter, dry to remove moisture, pulverize and grind to obtain nickel nitrate filled carbon nanofibers;

[0052] (2) Calcining the ferric nitrate-filled carbon nanofibers obtained in step (1) at 450° C. for 30 min in a nitrogen atmosphere to obtain the target product: carbon nanofibers filled with nickel oxide nanoparticles.

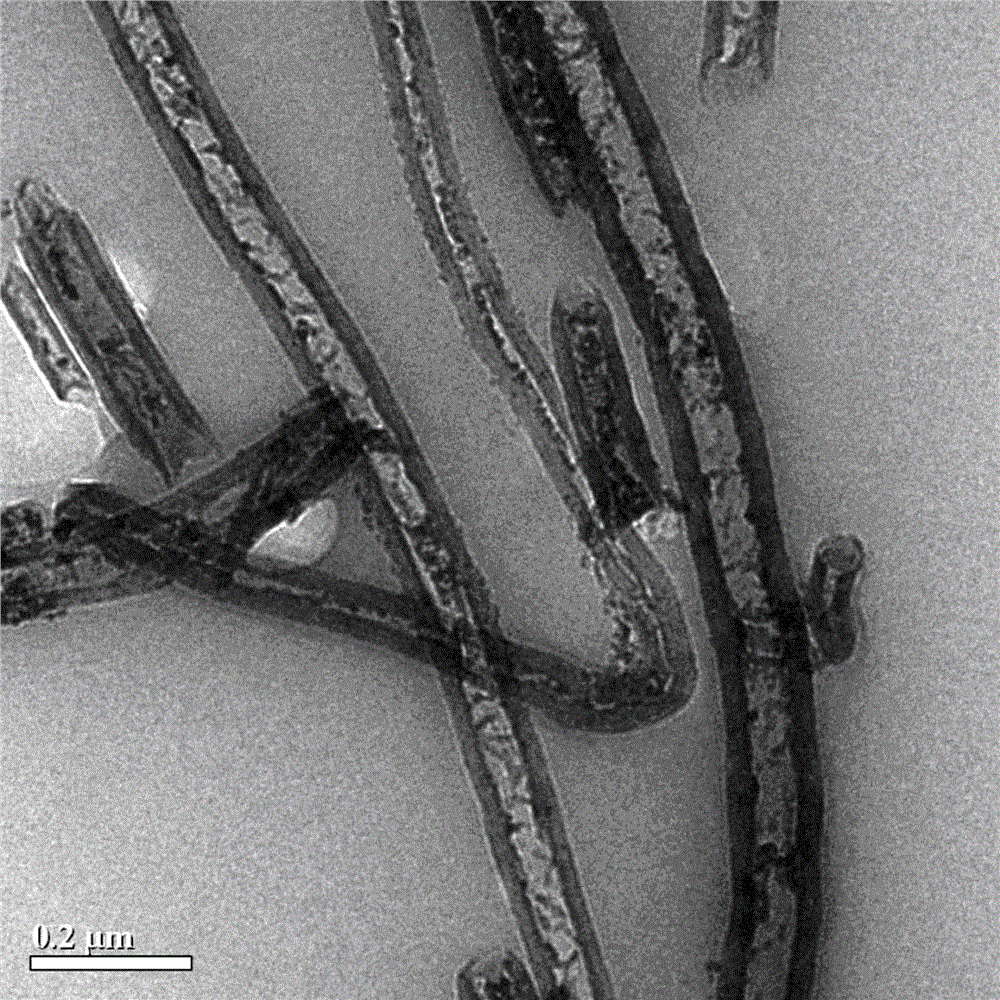

[0053] image 3 The transmission microscope photos of the carbon nanofiber tubes show fracture marks, the ports are open, and the tubes are continuously filled with nickel oxide nanoparticles with a high filling rate, and there are obvious free spaces around the nanoparticles in the tubes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com