Sectional wood strip polishing device

A polishing device and wood line technology, applied in the direction of grinding drive device, grinding/polishing equipment, grinding workpiece support, etc., can solve the problems of labor-intensive, poor effect, etc., achieve high grinding efficiency, flexible use and adaptability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

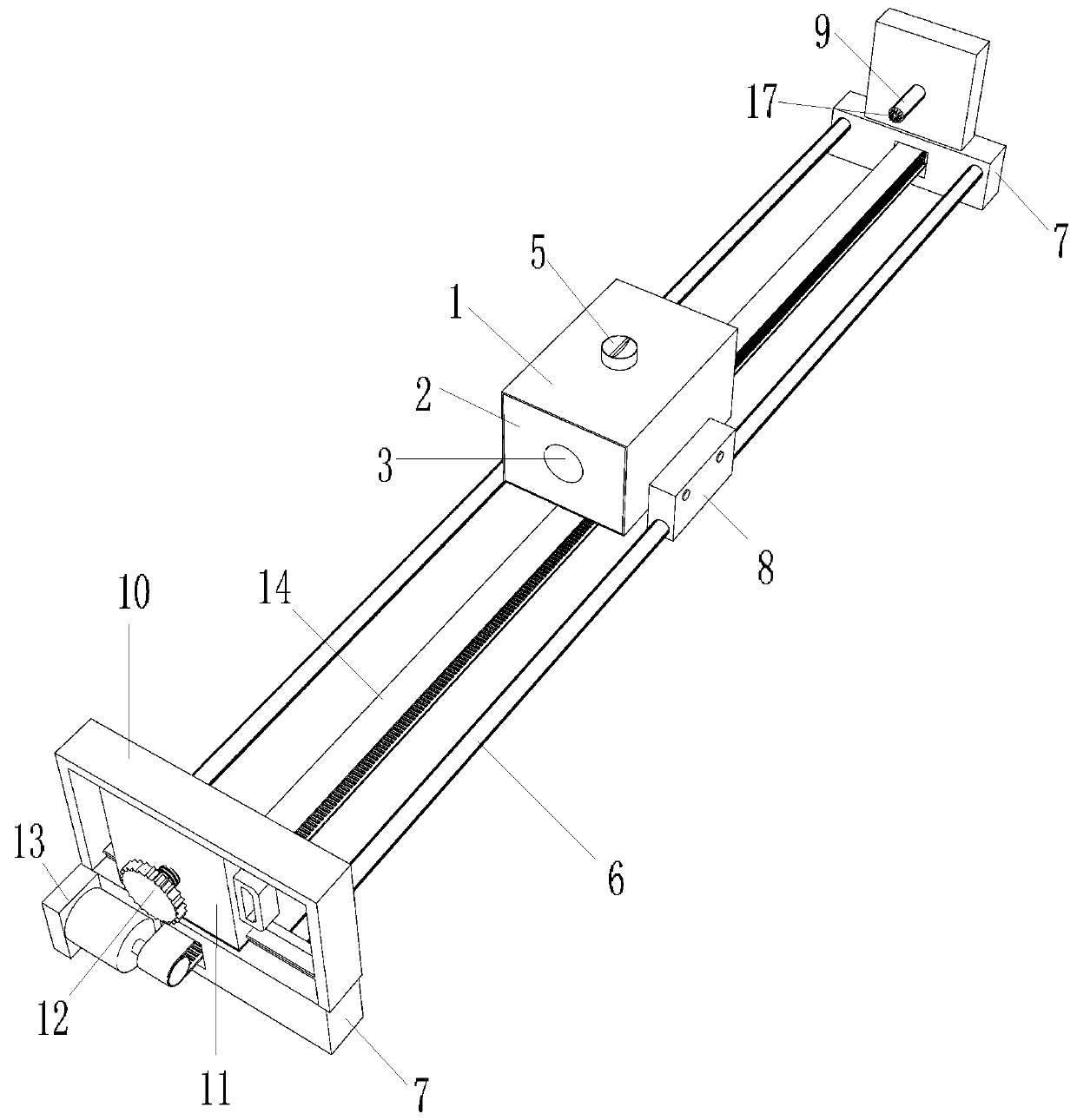

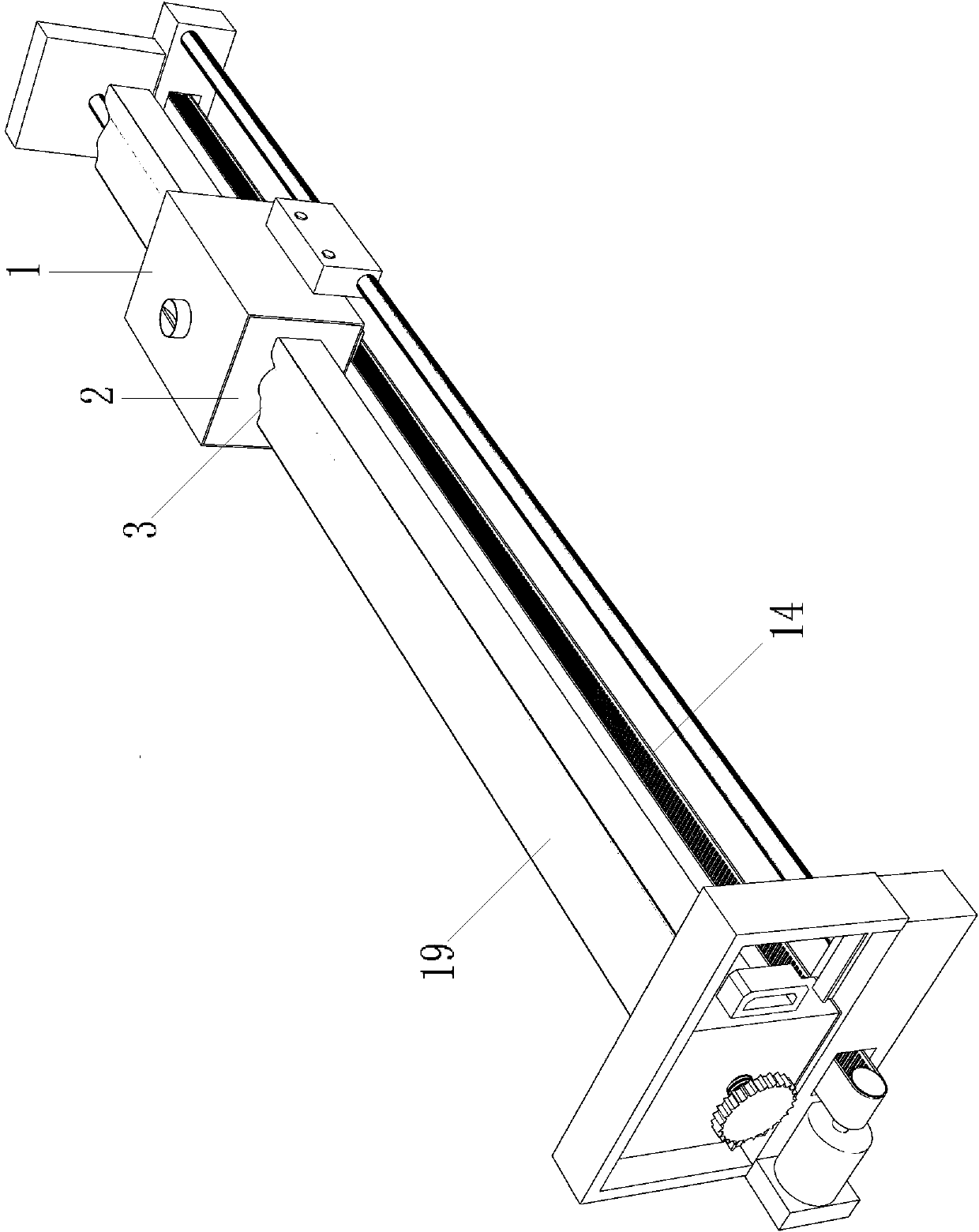

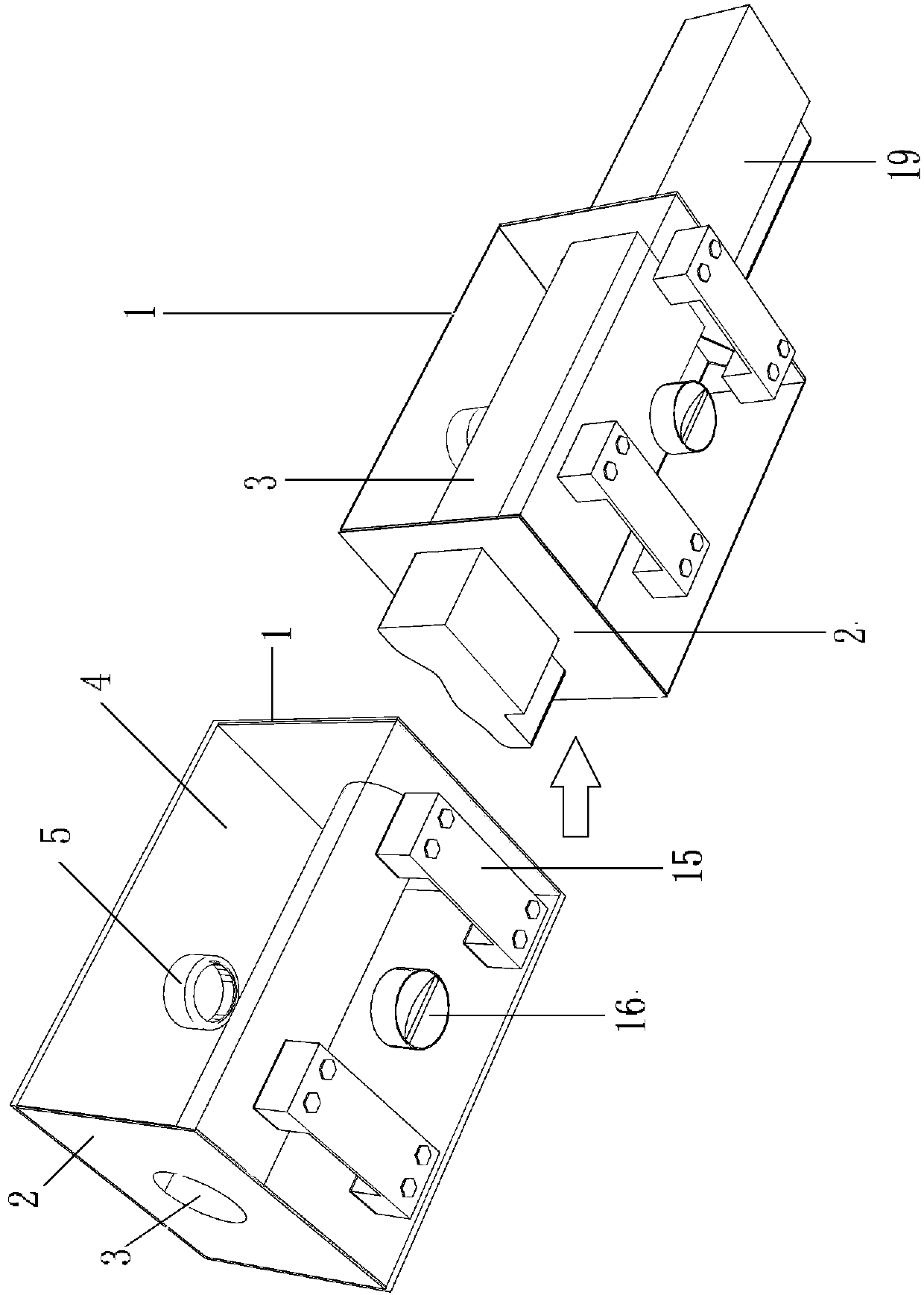

[0022] Such as Figure 1-3 As shown, the cross-sectional wood strip polishing device includes a polishing unit, a walking unit, and a supporting unit;

[0023] The shown polishing unit comprises a hard cylindrical shell 1, a soft elastic core cover 2 installed in the hard cylindrical shell 1; the soft elastic core cover 2 is dumbbell-shaped; The hard cylindrical shell 1 is sealed and connected; the center of the soft elastic core sleeve 2 is a polishing channel 3; the cavity between the hard cylindrical shell 1 and the soft elastic core sleeve 2 is the filling cabin 4; A hatch 5 is installed on the hard shell 1 at the top;

[0024] The support unit includes two guide support beams 6 arranged side by side in the middle, and support bases 7 fixed on the two ends of the two guide support beams 6; The slider 8 that is slidably connected to the support beam 6; the A positioning drill 9 is fixed on the rear support base 7, and the axis line of the A positioning drill 9 is aligned ...

Embodiment 2

[0031] The difference between the present embodiment and the first embodiment is: a cross-sectional wood molding polishing device, the bottom of the filling cabin 4 is equipped with a B hatch cover 16 on the hard cylinder shell 1; the filling cabin 4 is filled with soluble photosensitive resin; Quality tubular shell 1 is to have transparent organic glass material.

[0032] In the present embodiment, the filling fluid in the filling cabin 4 can adapt to the wood strips 19 of different cross-sectional shapes, but when it encounters an abrupt point, the shape of the polishing channel 3 may change because of the soft structure, and the abrupt point cannot be removed. Grinding off requires repeated manual grinding. This can be avoided by injecting soluble photosensitive resin: after the soluble photosensitive resin is injected, it is cured by irradiating the transparent hard cylindrical shell 1 with ultraviolet rays, so that the shape of the polishing channel 3 is fixed, so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com