Method for manufacturing side plate of bucket arm of excavator

A manufacturing method and excavator technology, which is applied in the field of excavator sticks, can solve the problems of multiple cranes and large floor area, and achieve the effects of reducing construction floor space, saving electricity costs, and reducing equipment input costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

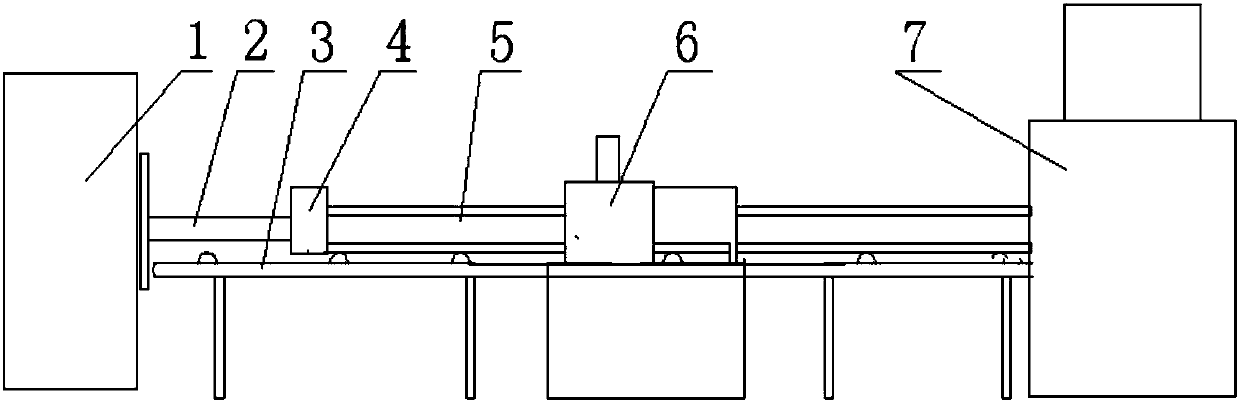

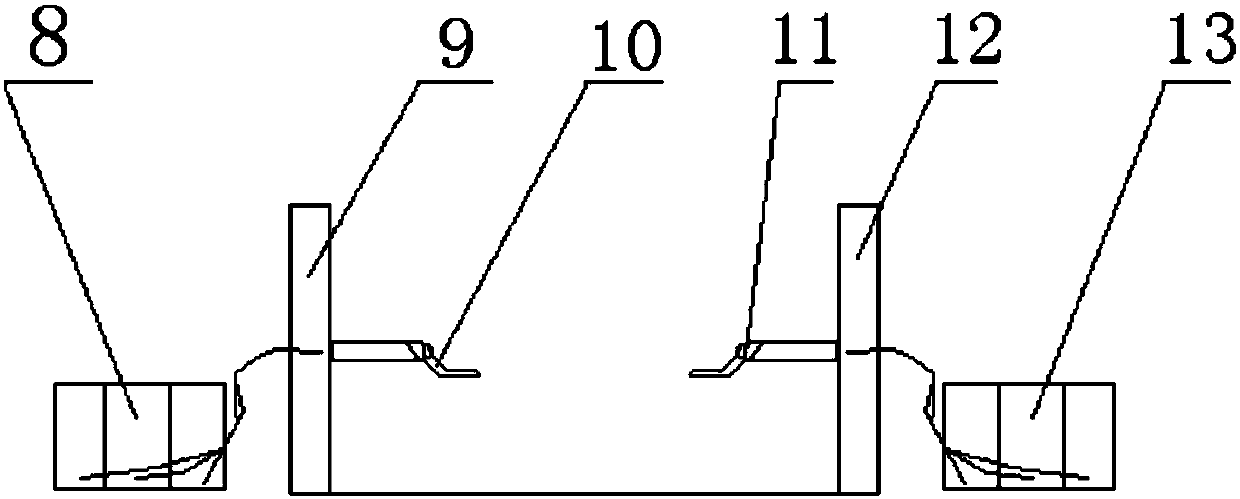

[0012] Such as figure 1 , figure 2 As shown, the excavator arm side plate X groove welding device includes the equipment body 7, the frame 3, the traction part 1, the arm workpiece group 5, the welding unit 6, the connecting rod 2 and the traction joint 4, and the frame 3 is arranged Between the equipment body 7 and the traction part 1, the welding unit 6 is arranged in the middle of the frame 3, and the arm workpiece group 5 is placed above the frame. Rod, the arm workpiece group is placed on the rolling rod of the frame. One end of the arm workpiece set 5 has a traction connector 4 , and a connecting rod is provided between the traction connector 4 and the traction part 1 . Welding unit 6 comprises the first welding machine 8, the first welding machine support 9, the first welding torch 10, the second welding machine 11, the second welding machine support 12 and the second welding torch 13, the first welding machine 8, the first welding machine The support 9 and the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com