Bevel gear milling fixture

A bevel gear and gear tooth technology, applied in the field of bevel gear milling fixtures, can solve problems such as unstable manufacturing quality, loss of chuck clamping force, and reduced product life, so as to improve machining accuracy and stability, and eliminate transmission Effects of improving gear backlash and rigidity conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will now be further described in conjunction with specific examples, and the following examples are intended to illustrate the present invention rather than further limit the present invention.

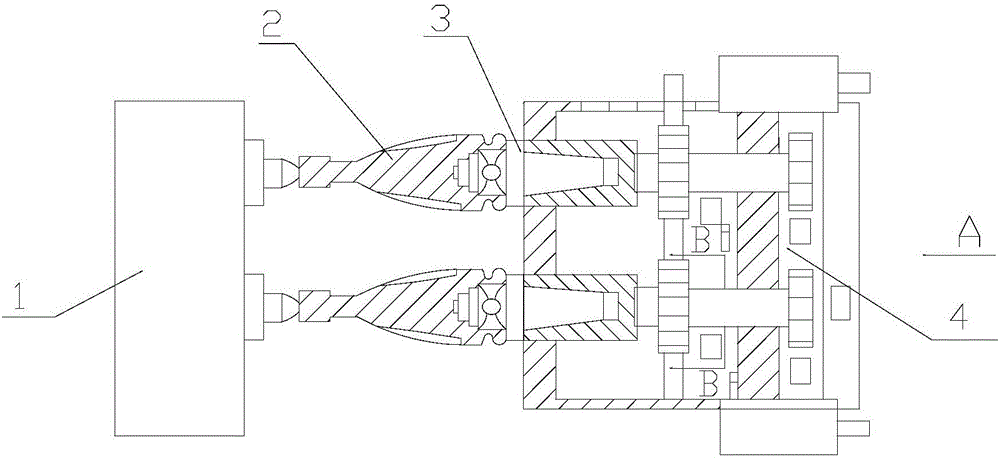

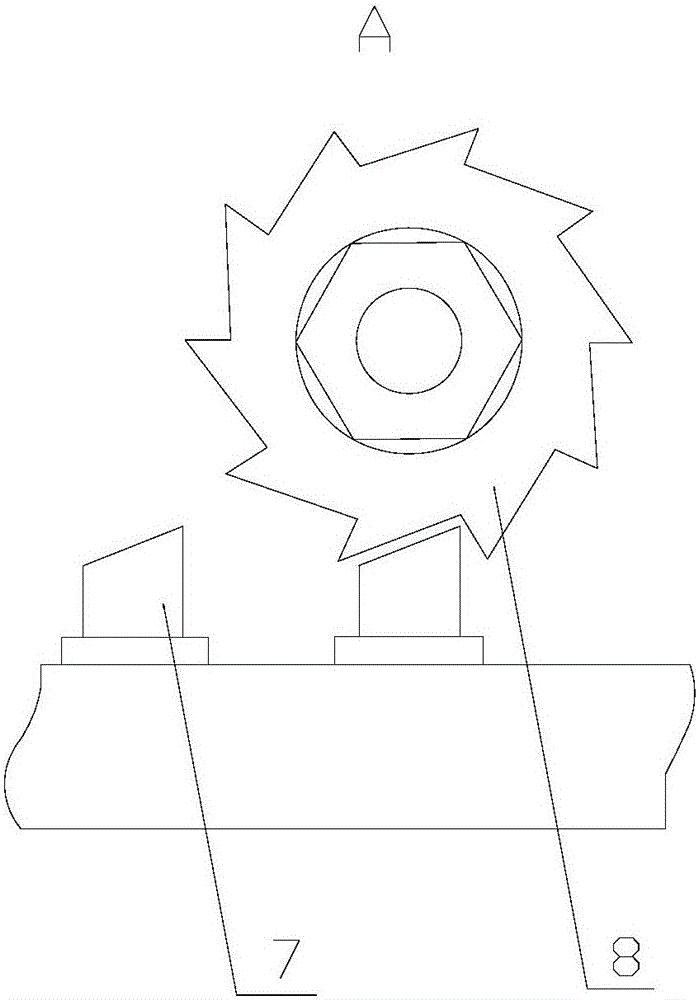

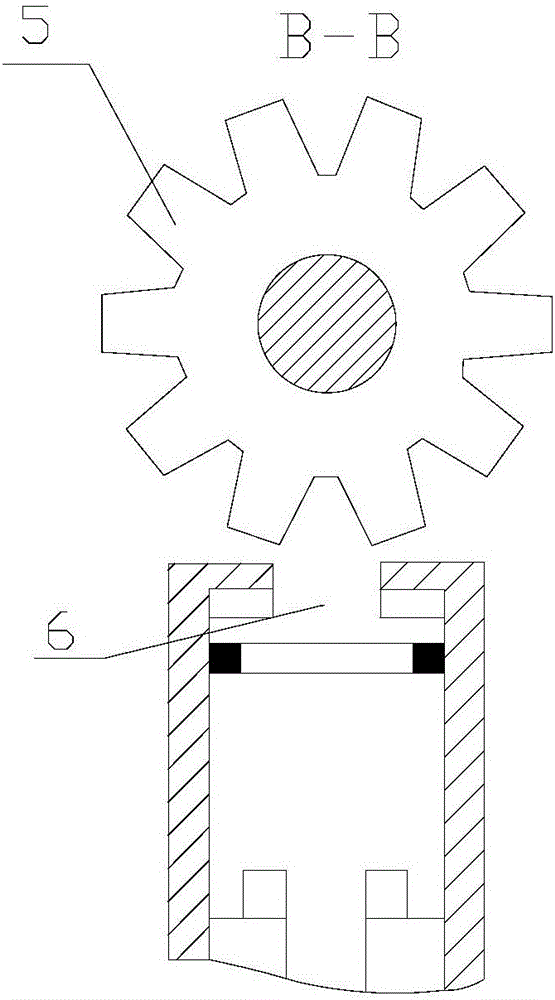

[0014] like Figure 1~3 As shown, a bevel gear milling fixture includes a positioning square tire 3, one end of the positioning square tire 3 is connected to one end of the bevel gear tooth blank 2, and the other end of the bevel gear tooth blank 2 is in contact with the hydraulically controlled tip device 1, The other end of the positioning square tire 3 is connected with a positioning indexing device 4. The positioning indexing device 4 includes a fine positioning indexing mechanism and a ratchet pawl auxiliary mechanism. The fine positioning indexing mechanism is composed of a toothed indexing plate 5 and a positioning Pin 6 forms, and ratchet pawl secondary mechanism comprises ratchet 8 and ratchet driving lever 7. Wherein, positioning square tire 3 l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com