moisture separator

A water vapor separator and drainage pipe technology, applied in the field of separators, can solve problems such as low water removal efficiency, poor heating effect, complex structure, etc., and achieve the effects of reducing hidden dangers, increasing temperature, and increasing heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

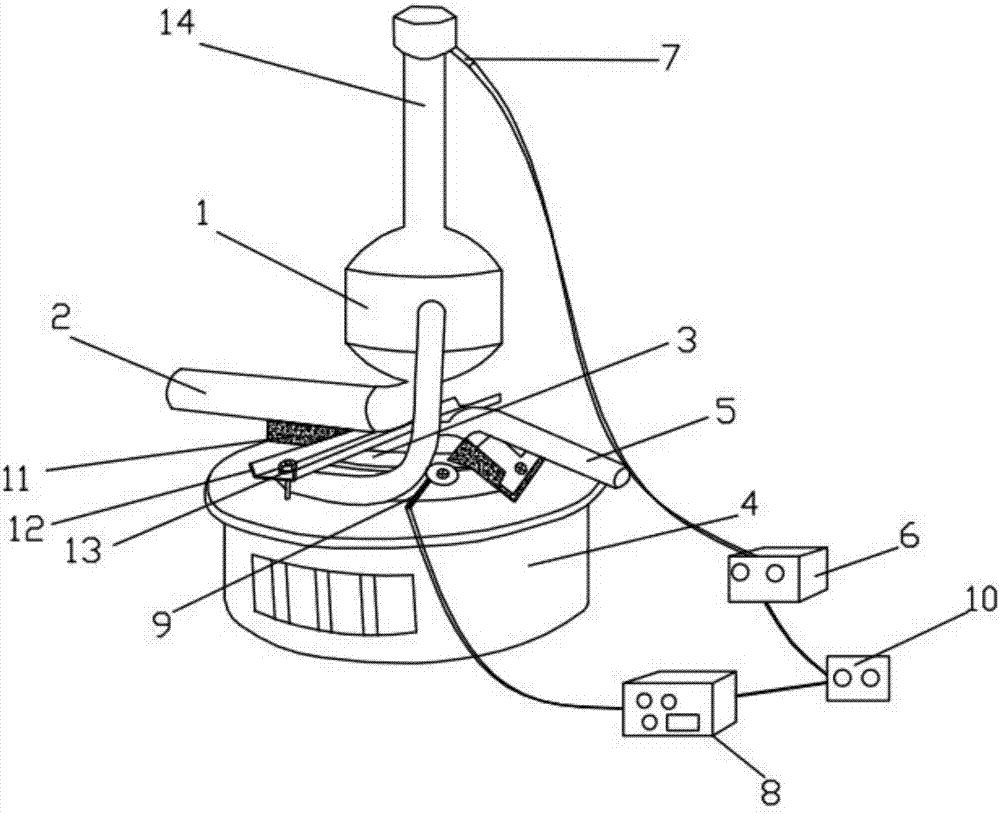

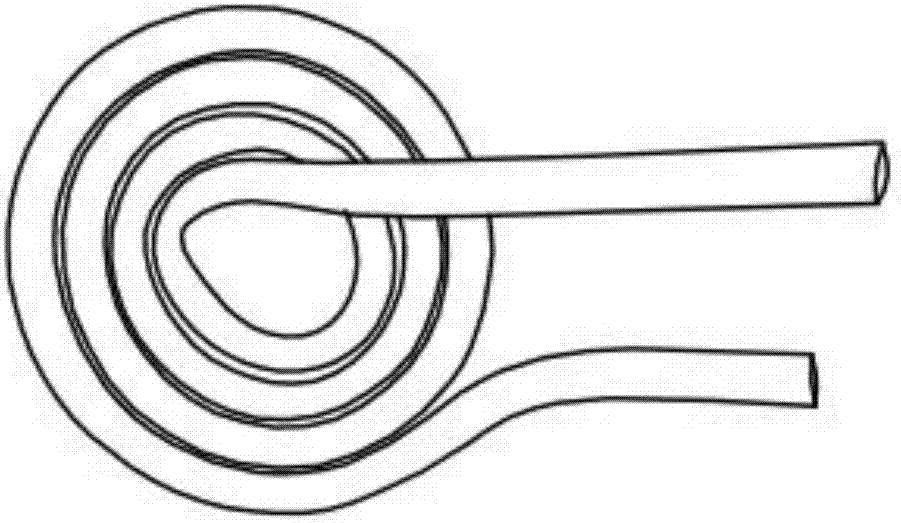

[0015] Such as figure 1 and figure 2 The water vapor separator shown includes a filter device 1 with a steam inlet pipe 14 at the upper end, a drain pipe 2 connected to the lower end of the filter device, a coil 3 connected to the filter device at one end, and a heating device 4 for heating the coil. The tube is closely attached to the heating surface of the heating device, and the side of the coil that is close to the heating device can be designed as a plane, that is, the coil that is in contact with the heating device is designed to have an O-shaped structure in section, so that the contact between the coil and the heating device The area is the largest and the thermal efficiency is the best. One end of the coil is connected to the filter device 1, and the other end is the steam outlet 5. The end of the coil connected to the filter device is set above the horizontal position of the drain pipe, and also includes a pressure controller to control the pressure inside the filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com