Method for improving sensory quality of reconstituted tobacco

A technology for reconstituting tobacco leaves and quality, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of complex operation, poor industrial applicability, and high recovery cost, and achieve the effects of improving sensory quality, reducing economic costs, and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

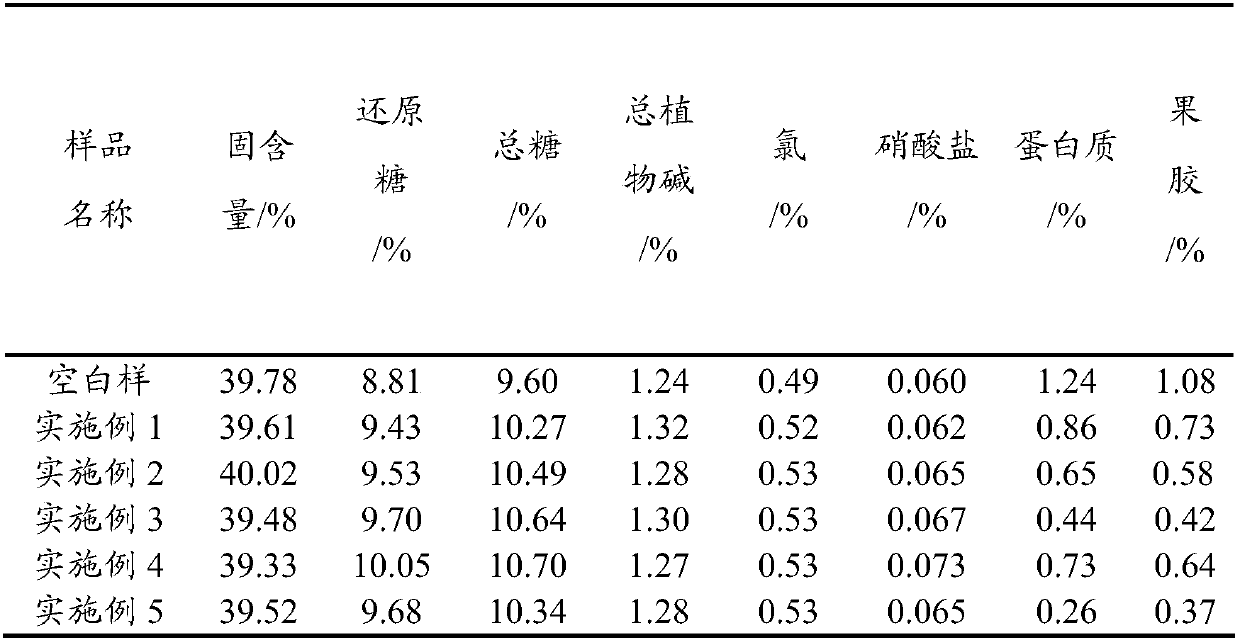

Examples

Embodiment 1

[0016] Tobacco raw materials and added wood pulp fibers are fed at a dry weight ratio of 10:1. Tobacco raw materials such as tobacco stems and tobacco powder are extracted and separated from solid and liquid to obtain extract solids and extracts. The solids are beaten by a refiner to 20± 2 O SR, plus wood pulp, beating to 40±2 by refiner O Sr. After the tobacco stem pulp is mixed with the added wood pulp, add light calcium carbonate accounting for 7% of the dry mass of the mixed pulp to make the pulp and adjust the concentration, and carry out papermaking according to the set concentration to obtain a quantitative value of about 60g / m2 reconstituted tobacco leaf substrate.

[0017] Add the same mass of glacial acetic acid into food-grade chitosan with a deacetylation degree of 85% and a molecular weight of 50,000, add water, stir and dissolve, and prepare a chitosan solution with a mass concentration of 0.1%. According to chitosan accounts for 0.01% of the solid content of ...

Embodiment 2

[0019] Tobacco raw materials and added wood pulp fibers are fed at a dry weight ratio of 10:1. Tobacco raw materials such as tobacco stems and tobacco powder are extracted and separated from solid and liquid to obtain extract solids and extracts. The solids are beaten by a refiner to 20± 2 O SR, plus wood pulp, beating to 40±2 by refiner O Sr. After the tobacco stem pulp is mixed with the added wood pulp, add light calcium carbonate accounting for 7% of the dry mass of the mixed pulp to make the pulp and adjust the concentration, and carry out papermaking according to the set concentration to obtain a quantitative value of about 60g / m2 reconstituted tobacco leaf substrate.

[0020] Add the same mass of glacial acetic acid into food-grade chitosan with a deacetylation degree of 85% and a molecular weight of 100,000, add water, stir and dissolve, and prepare a chitosan solution with a mass concentration of 0.2%. According to chitosan accounts for 0.04% of the solid content of...

Embodiment 3

[0022] Tobacco raw materials and added wood pulp fibers are fed at a dry weight ratio of 10:1. Tobacco raw materials such as tobacco stems and tobacco powder are extracted and separated from solid and liquid to obtain extract solids and extracts. The solids are beaten to 20± 2 O SR, plus wood pulp, beating to 40±2 by refiner O Sr. After the tobacco stem pulp is mixed with the added wood pulp, add light calcium carbonate accounting for 7% of the dry mass of the mixed pulp for pulp blending and thickening, and make paper according to the set concentration to obtain a quantitative value of about 60g / m2 reconstituted tobacco leaf substrate.

[0023] Add the same mass of glacial acetic acid into food-grade chitosan with a deacetylation degree of 90% and a molecular weight of 50,000, add water, stir and dissolve, and prepare a chitosan solution with a mass concentration of 0.5%. According to chitosan accounts for 0.06% of the solid content of the extract solution, the chitosan so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com