Sea salt and folium isatidis extract containing plant salt and method for preparing plant salt by using heavy metal ion removal process through nanofiber membrane

A technology of Folium Folium extract and nanofiber membrane, applied in the field of development and utilization of plant salt, can solve the problems of no traditional Chinese medicine ingredients, high NaCl content of table salt, and easy caking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

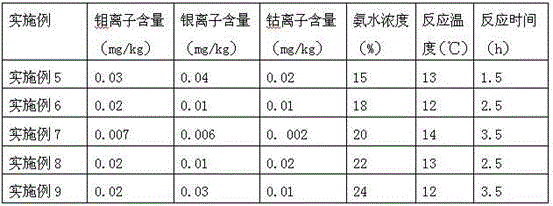

Examples

Embodiment 1

[0034] Example 1: Preparation of Plant Salt Containing Sea Salt and Folium Folium Extract

[0035] Step 1. Preparation of refined brine

[0036] (1) Brine collection

[0037] Add potassium ferrocyanide to refined saturated brine with a pH value of 7 to prepare a 0.2 mg / L potassium ferrocyanide solution, then add sodium carbonate and calcium chloride, stir, stand still, and precipitate to remove Most of the Ca2+, Mg2+, and Fe2+ ions in the brine can be used to obtain relatively pure brine. In the brine, the detected molybdenum ion content is 10mg / L, the silver ion content is 10mg / L, and the cobalt ion content is 15mg / L.

[0038] (2) filter

[0039] Mechanical filtration: The collected brine is mechanically filtered to remove large solid impurities and mechanical impurities; the first layer is activated alumina as the filter material, and the second layer uses quartz sand as the filter material. The first filter material The specification of the first filter material is 2mm,...

Embodiment 2

[0064] Embodiment 2: Preparation of plant salt containing sea salt and Folium folium extract

[0065] Step 1. Preparation of refined brine

[0066] (1) Brine collection

[0067] Add potassium ferrocyanide to saturated brine with a pH value of 8 to prepare a potassium ferrocyanide solution with a concentration of 0.5 mg / L, then add sodium carbonate and calcium chloride, let stand, precipitate, and filter to remove the brine Most of the Ca2+, Mg2+, Fe2+ plasma in the medium can get relatively pure brine. In the brine, the molybdenum ion content was detected to be 15mg / L, the silver ion content was 15mg / L, and the cobalt ion content was 20mg / L.

[0068] (2) filter

[0069] Mechanical filtration: The collected brine is mechanically filtered to remove large solid impurities and mechanical impurities; the first layer is activated alumina as the filter material, and the second layer uses quartz sand as the filter material. The first filter material The specification of the first ...

Embodiment 3

[0093] Embodiment 3: the preparation of the plant salt containing sea salt and Folium folium extract

[0094] Step 1. Preparation of refined brine

[0095] (1) Brine collection

[0096] Add potassium ferrocyanide to refined saturated brine with a pH value of 9 to prepare a potassium ferrocyanide solution with a concentration of 0.8 mg / L, then add sodium carbonate and calcium chloride, let stand, precipitate, filter, and remove Most of the Ca2+, Mg2+, and Fe2+ ions in the brine can be used to obtain relatively pure brine. In the brine, the detected content of molybdenum ions is 20mg / L, the content of silver ions is 20mg / L, and the content of cobalt ions is 25mg / L.

[0097] (2) filter

[0098] Mechanical filtration: The collected brine is mechanically filtered to remove large solid impurities and mechanical impurities; for mechanical filtration, activated alumina is used as the filter material for the first time, and quartz sand is used as the filter material for the second l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com