Preparation method of solid-state and multi-microorganism citric acid acidized fermented feed

A technology of multi-bacteria citric acid and citric acid, which is applied in the fields of feed, enzyme preparations and microorganisms, can solve the problems of expensive raw materials, difficulty in using fiber and waste residue and waste liquid, and does not involve the addition of Chinese herbal medicines, etc., to achieve digestible content and palatability The effect of good sex and high nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

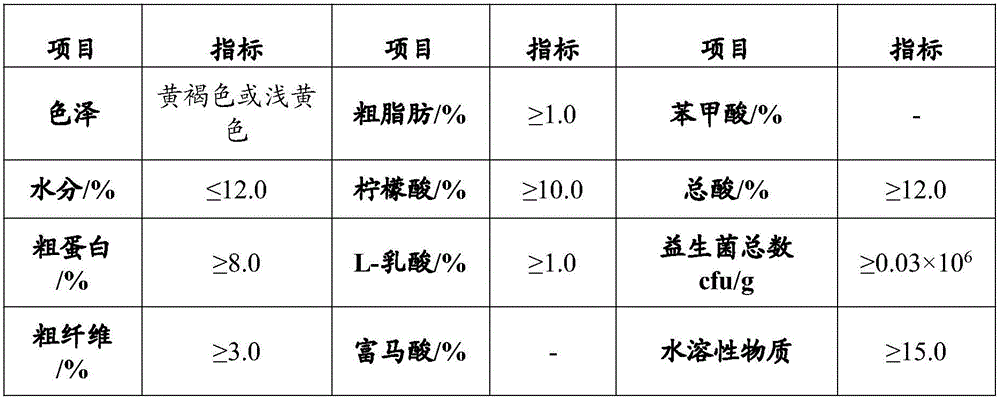

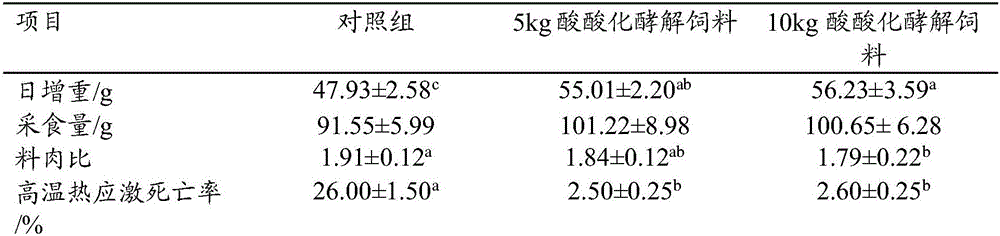

Image

Examples

Embodiment 1

[0098] A kind of preparation of solid multi-bacteria citric acid acidified fermented feed comprises the following steps:

[0099] ①. Preparation of wet base of citric acid solid-state fermentation medium:

[0100] Mix 80kg of clean water, 80kg of rice, 20kg of sucrose molasses, 80kg of bran, 2kg of stone powder, and 1.8kg of ammonium nitrate, sterilize at high temperature, and cool to obtain a solid-state fermentation medium, sterilize and cool at high temperature, and insert 25kg of citric acid bacteria Seed liquid, under the conditions of 22-26 °C, natural fermentation pH and continuous supplementation of 20 kg of sterile water, carry out aerobic fermentation for 120 hours to obtain 302-305 kg of citric acid solid-state fermentation medium wet base;

[0101] ②. Preparation of fermented feed wet base:

[0102] After mixing 80kg of clean water, 85kg of bran, 20kg of molasses and 80kg of corn gluten powder, high-temperature sterilization and cooling to obtain a solid-state fer...

Embodiment 2

[0107] A kind of preparation of solid multi-bacteria citric acid acidified fermented feed comprises the following steps:

[0108] ①. Preparation of wet base of citric acid solid-state fermentation medium:

[0109] Mix 80kg of clean water, 120kg of corn, 20kg of molasses, 40kg of bran, 2kg of stone powder, and 1.8kg of ammonium nitrate, sterilize at high temperature, and cool to prepare a solid-state fermentation medium, sterilize and cool at high temperature, and insert 25kg of citric acid bacteria Under the conditions of 22-26°C, natural fermentation pH and continuous supplementation of 20kg sterile water, carry out aerobic fermentation for 132 hours to obtain 302-305kg wet base of citric acid solid-state fermentation medium;

[0110] ②. Preparation of fermented feed wet base:

[0111] Mix 80kg of clean water, 50kg of bran, 35kg of soybean meal, 20kg of molasses and 80kg of corn gluten powder, sterilize at high temperature and cool to prepare a solid fermentation medium, ste...

Embodiment 3

[0116] A kind of preparation of solid multi-bacteria citric acid acidified fermented feed comprises the following steps:

[0117] ①. Preparation of wet base of citric acid solid-state fermentation medium:

[0118] Mix 160kg of clean water, 200kg of cassava, 40kg of broken rice, 40kg of molasses, 80kg of bran, 4kg of stone powder, and 3.5kg of ammonium nitrate, sterilize at high temperature, and cool to obtain a solid-state fermentation medium. After high-temperature sterilization and cooling, insert 60kg Citric acid bacteria seed liquid, under the conditions of 24-26 ° C, natural fermentation pH and continuous supplementation of 40 kg of sterile water, carry out aerobic fermentation for 132 hours to obtain 610-620 kg of citric acid solid-state fermentation medium wet base;

[0119] ②. Preparation of fermented feed wet base:

[0120] Mix 80kg of clean water, 55kg of rice bran, 60kg of soybean meal, 10kg of molasses and 60kg of corn gluten powder, sterilize at high temperature,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com