Liquid developer

A developer and liquid technology, applied in developer, electrography, optics, etc., can solve the problem of coexistence of migration of substrates that cannot be electrophoretic printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

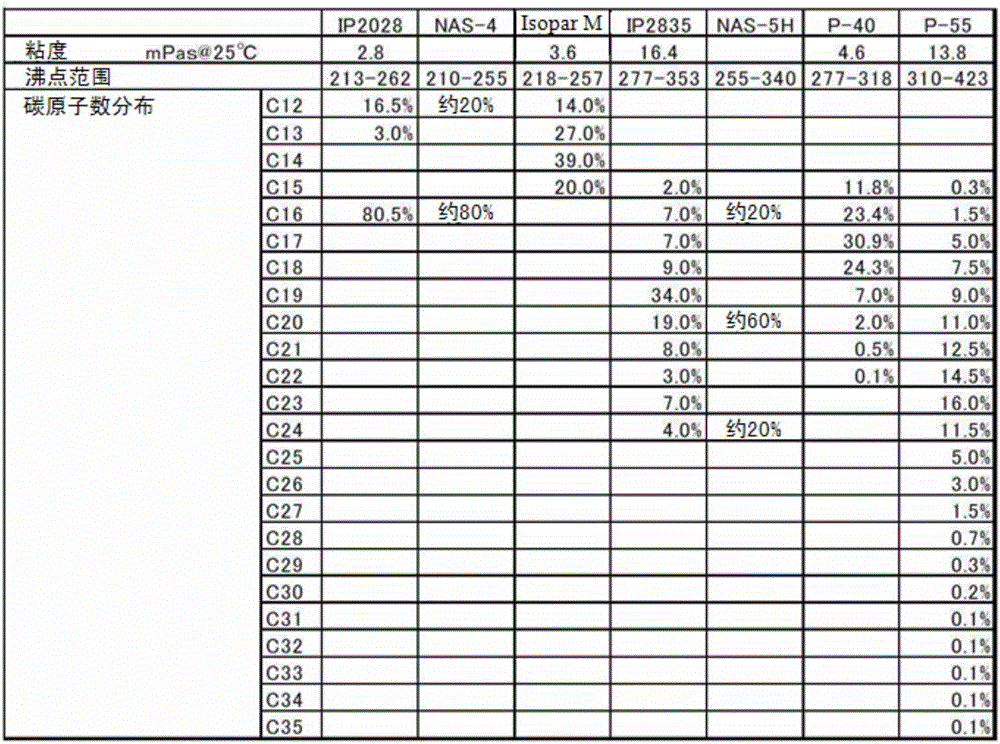

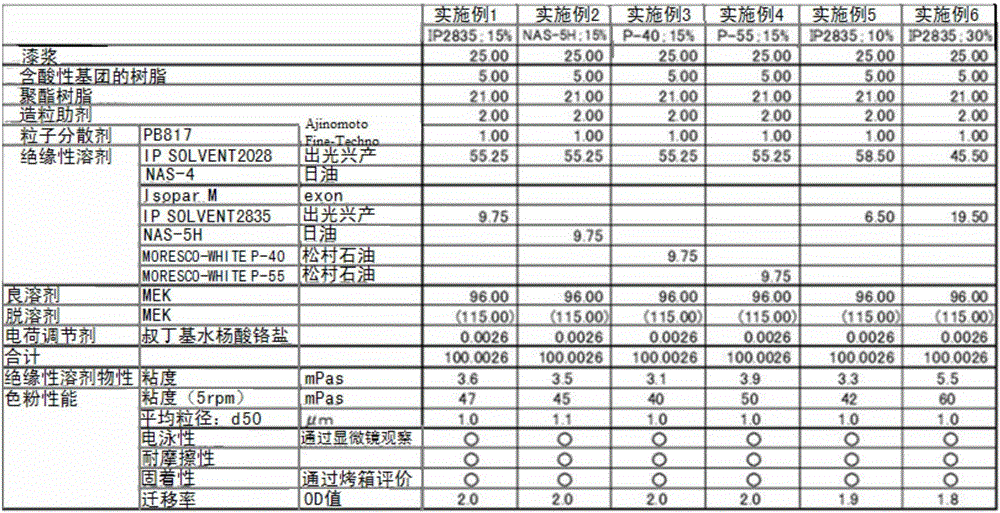

[0132] As an insulating solvent, IP SOLVENT2028 / IP SOLVENT2385=85 / 15 was used.

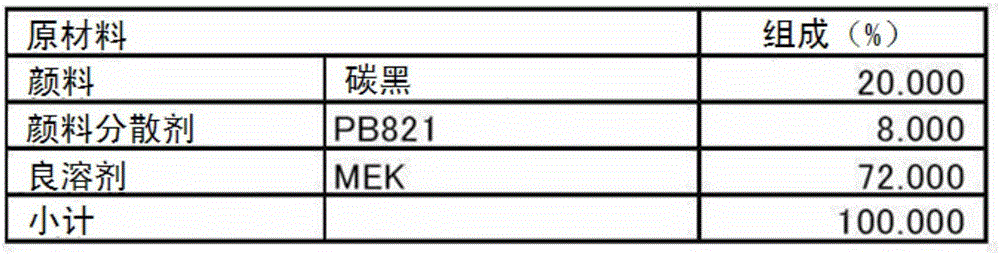

[0133] 20.00 parts of pigment (acid carbon black at pH 2.8), 8.00 parts of pigment dispersant (PB821, manufactured by Ajinomoto Fine Chemical Co., Ltd.), and 72.00 parts of methyl ethyl ketone were mixed, and passed through a paint mixer (paint mixer) with a steel ball with a diameter of 5 mm. shaker) for 15 minutes, and further kneaded for 2 hours by Eiger Motormill M-250 (manufactured by Eiger Japan) using zirconia beads with a diameter of 0.05 mm. 25.00 parts of this kneaded product was used as a millbase, and 21.00 parts of an acidic group-containing polyester resin as a binder resin, 5.00 parts of an acidic group-containing resin, and a granulation aid (solid content 50% ) and 96.00 parts of methyl ethyl ketone were heated and stirred at 50°C.

[0134] Then, after adding 1.00 parts of particle dispersants and stirring, it stirred while diluting with 55.25 parts of IP SOLVENT2028 which is an ...

Embodiment 2

[0136] Except having changed IP SOLVENT2835 of an insulating solvent (B) into NAS-5H, it carried out similarly to Example 1, and obtained the liquid developer of Example 2.

Embodiment 3

[0138] Except having changed IP SOLVENT2835 of an insulating solvent (B) into Moresco-White P-40, it carried out similarly to Example 1, and obtained the liquid developer of Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com